Safety isn’t a suggestion in the food and beverage industry; it’s a legal and ethical requirement. One essential tool in maintaining these high standards is the food safety audit, a systematic process ensuring your facility complies with current laws, regulatory expectations, and industry best practices.

Whether required by customers, retailers, or government agencies, food safety audits help identify potential risks before they become costly issues.

In this guide, we’ll explore what food safety audits are, the types you may encounter, and how to prepare for them effectively.

What Is a Food Safety Audit?

A food safety audit is a careful and systematic examination of a food manufacturing facility’s systems, processes, and operations to ensure compliance with food safety standards. It helps identify potential hazards and assess whether the facility’s food safety management system is efficient enough.

According to the research, the global Food Safety Audit and Certification Services market is expected to reach $8597.5 million in 2029, up from $5800 million in 2022. The CAGR from 2023 to 2029 is 5.8%.

Audits typically assess:

- Your written food safety management system (FSMS)

- Sanitation and hygiene practices

- Employee training and awareness

- Supplier and traceability controls

- Documentation accuracy and real-time monitoring

Government regulators like the FDA or USDA may require food safety audits, certification bodies like SQFI or BRC, or even retail partners like Costco or Whole Foods.

What Are the Types of Food Safety Audits?

Food safety audits can be internal or external.

Internal audits are first-party audits conducted by the food business itself.

External audits can be second-party, meaning the audits of your supplier, and third-party, where independent auditors or certification bodies conduct audits.

Third-party audits are typically required for recognized certifications (SQF, BRC, ISO 22000) and often follow global benchmarks like GFSI. These audits are conducted by accredited certification bodies and are considered highly credible in worldwide trade and retail acceptance.

Pass Your Next Audit with Confidence

From SQF to FDA inspections, FoodReady’s digital tools and expert consultants give you full support through every stage of audit prep.

What is the Importance of Food Safety Audits?

Food safety audits focus on critical aspects of food and beverage manufacturing and play a key role in protecting public health. They help businesses identify and eliminate potential sources of food contamination before they result in foodborne illness outbreaks.

These audits offer broad operational and strategic advantages, including:

- Preventing contamination and foodborne illnesses by identifying high-risk areas in sanitation, handling, and processing

- Improving employee training and competence, ensuring staff understand and follow proper food safety protocols

- Enhancing internal communication and teamwork, fostering a stronger food safety culture across departments

- Increasing productivity and staff morale, as employees feel more involved and empowered

- Identifying gaps in operations, allowing companies to improve their food safety systems continuously

- Protecting product quality and brand reputation, which is essential in competitive markets

- Facilitating market expansion, both domestically and internationally, by meeting regulatory and customer requirements

- Ensuring regulatory compliance, reducing the risk of fines, recalls, or shutdowns

In short, food safety audits help manufacturers prove that their products are safe, consistent, and aligned with all applicable standards, making audits a necessity and a strategic advantage. According to the USDA, foodborne illnesses cost the U.S. economy over $15.6 billion annually. A strong audit program helps businesses identify and mitigate risks before they escalate into public health issues or brand damage.

How Is a Food Safety Audit Done? (Step-By-Step)

A food safety audit process includes different steps, from planning to the actual audit. Let’s examine it in more detail.

1. Planning and Preparation

Planning and preparation for a food safety audit can take several months to a year. It will involve training, documentation, and other steps that we will discuss later.

2. Audit Execution

At the established date, certification bodies arrive at a facility, interview the facility’s employees, and conduct the audit, assessing the state of the company’s operations, food safety system, documentation, etc.

3. Corrective and Preventive Actions

Auditors want to check how you address hazards or gaps found during the audit. If any nonconformances are found, the company must implement corrective and preventive actions to resolve the issue before the deadline established by a certification body.

4. Verification

At this stage, an auditor will check whether you successfully implemented preventive and corrective actions and whether everything works well. It confirms that your facility meets the needed standards.

5. Audit Evaluation

The final step is when the auditors assess how well you handled the audit and announce the result.

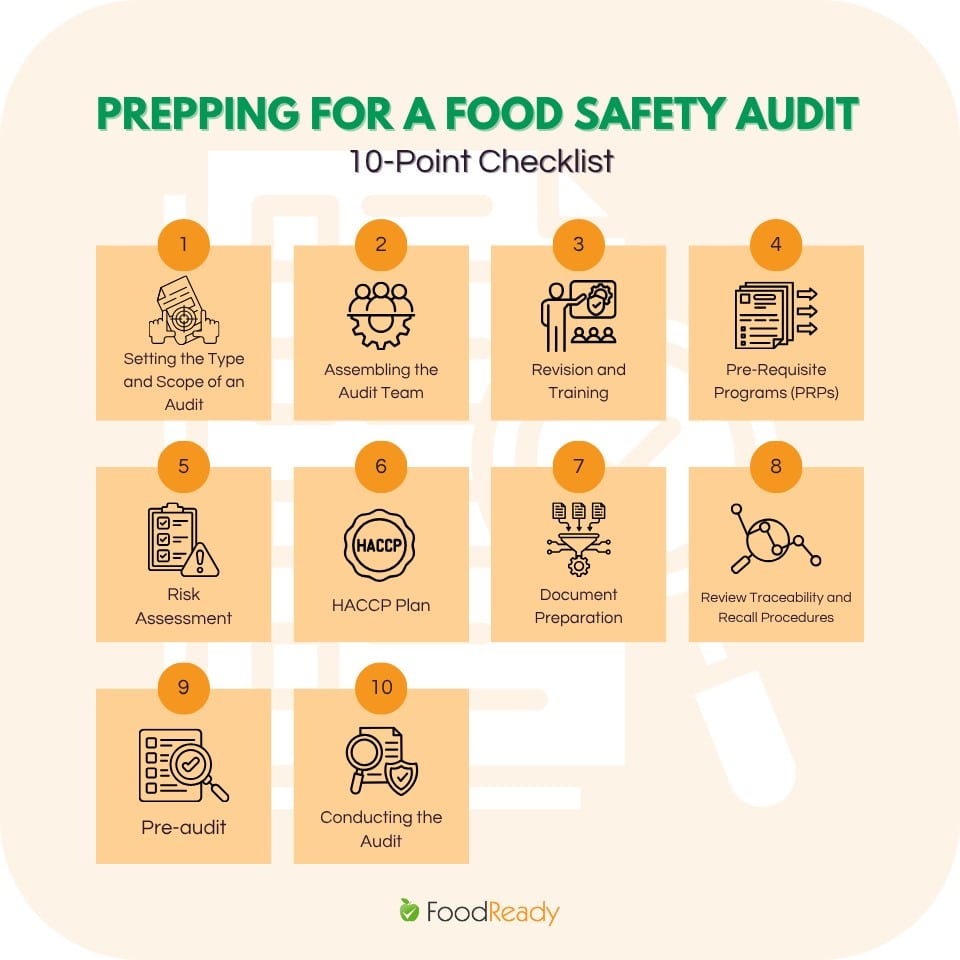

10-Point Checklist for Food Safety Audit Preparation

We’ve created an audit preparation checklist so you can understand how to prepare for a food safety audit.

- Setting the Type and Scope of an Audit: If you decide to pass the audit, you must understand the type of audit you take (GFSI, HACCP, FDA), its scope, and requirements.

- Assembling the Audit Team: The company that plans to undertake the audit must gather a responsible team.

- Revision and Training: Make sure you and your employees fully understand and are aware of food safety practices, requirements of the food safety audit, and so on. You or other food handlers can be interviewed and checked to ensure you work according to the standards.

- Pre-Requisite Programs (PRPs): Prerequisite programs like GMP (Good Manufacturing Practices) are the basis of a food safety management system and are key to a successful audit.

- Risk Assessment: The procedure will help identify and resolve issues before the food safety audit.

- HACCP Plan: Develop and implement a comprehensive and structured HACCP plan. Although it’s not obligatory, the plan is essential to successfully pass the audit, as it demonstrates your proactive attitude to handling food safety hazards.

- Document Preparation: Properly document your food safety management system and keep all your records accessible for auditors, as they can require them for review during the audits. The document management system should include your food production operations, SOPs, HACCP, PRPs, traceability system, batch records, environmental monitoring program, etc. Remember about supplier documentation as well. Review and keep supplier documentation up to date, as auditors may want to check supplier records, certifications, etc.

- Review Traceability and Recall Procedures: You must ensure your food traceability system works seamlessly. Also, conduct a mock recall to prove you can quickly handle affected products.

- Pre-audit: You should conduct an internal audit before the third-party audit to find areas for improvement and gaps between your practices and the given criteria.

- Conducting the Audit: On the audit day, stay calm, professional, and cooperative, greet your auditors, and confidently demonstrate how compliant you are.

After the audit, you need to be ready for corrective actions and continuous improvement.

These are the general strategies for a successful food safety audit, but you can continue the research and read our blogs on how to prepare for an SQF audit or how to prepare for a Costco audit or browse our website to see more.

FoodReady: Your Partner in Successful Audit Preparation!

FoodReady food safety software is an affordable and universal solution for food manufacturers who want to pass a food safety audit, such as GFSI, GMP, FDA, etc.

The software gathers and streamlines all your operations, including monitoring, document management, traceability, sanitation procedures, HACCP, CCPs, and CAPA management.

Additionally, you can contact our food safety consultants, who will alleviate the audit preparation for you and help you foresee every detail to avoid mistakes.

FoodReady has many customers – thriving food and beverage companies searching for a solution to improve food safety compliance and ace the next audit. We are thrilled to see their growth and share success stories with you.

Eurobake’s new owner, Josh Svenhard, was searching for new sales opportunities but faced a challenge: the company needed a robust food safety plan to meet FDA standards under FSMA. Moreover, most customers demanded a third-party audit.

For this purpose, Eurobake selected FoodReady and chose to work toward GFSI/Costco audit readiness.

Josh wanted to get compliant faster, and we didn’t disappoint him! Eurobake passed its first third-party audit, meeting Costco’s requirements after 5 months with FoodReady. Moreover, they succeeded in a surprise FDA audit after only a few weeks of using the platform.

FoodReady provided Eurobake with HACCP plans, SSOPs (Standard Operating Procedures), PRPs (pre-requisite programs), and checklists for different purposes, including batch management, traceability, sanitation, etc.

With FoodReady, Eurobake has greatly expanded its customer base and achieved food safety goals. Book a demo with us today and begin a successful food safety audit journey!

Wrapping Up

Food safety audits are indispensable in the food and beverage industry, and food manufacturers must know how to prepare for and handle them to avoid costly mistakes and stress.

Generally, food safety audit preparation consists of different stages: certification selection, choosing a team, training, PRPs, documentation, HACCP plan, risk assessment, mock recalls, etc.

Food safety audits can be different and require a thorough understanding of crucial aspects, so addressing a food safety software provider can be a lifesaver.

FoodReady will guide you through each audit preparation step and continue to support you afterward. Contact us for more information and to digitize your food safety compliance!

FAQs

Food and beverage manufacturers should follow the FDA, FSMA, HACCP, and USDA regulations.

There are various reputable and well-known certifications, such as GFSI-recognized schemes like BRC or SQF. There are also retail-specific certifications, such as Costco.

If you are in two minds about which audit to undergo, read our blog about which food safety certification is the best.

Some common pitfalls to avoid in food safety audits are improper documentation, lack of an audit plan, or insufficient employee training.

Food safety consultants will support you and enhance your audit preparation process. They will conduct pre-audits, find areas for improvement, prepare documentation, etc.

In this case, you will receive a list of nonconformances. You must implement corrective actions within a given time, and then you will be re-evaluated.

Food safety audits are more comprehensive than food safety inspections.