Are you starting your HACCP journey? Writing a HACCP plan or preparing for the audit can require a lot of research, and it’s always confusing as HACCP includes a lot of aspects, stages, and rules.

Don’t worry, you won’t get lost! We’ve done the research for you and compiled everything into a well-detailed HACCP plan guide where you’ll find everything you need to know.

What Is a HACCP Plan?

A HACCP plan is a written document that outlines how a food business identifies, evaluates, and controls food safety hazards using the principles of Hazard Analysis and Critical Control Points (HACCP).

It includes a step-by-step assessment of the production process, highlights where risks may occur, and defines the preventive actions and monitoring procedures used to ensure food safety. Each plan is unique to the product and facility it covers, and it is required for compliance with many national and international food safety regulations.

Why Do You Need a HACCP Plan?

Although the HACCP plan is sometimes voluntary, there are some factors to consider, like the benefits of HACCP, business development, and legal requirements.

First and foremost, food safety is the most essential reason for having a HACCP plan. It helps identify and mitigate risks, ensuring the safety of consumers. As a result, your clients are healthy and satisfied.

You will improve your product quality, encouraging customers to return, which will make your business increasingly reliable.

FDA made implementing HACCP compulsory within specific food and beverage industry branches. It is described in the Food Safety Modernization Act (FSMA), which came into force in 2011.

The FDA’s primary goal is to prevent foodborne illnesses rather than deal with them afterward. And the HACCP plan is the best way to stick to these principles. So, once you have a program, you can be safe from legal issues, fines, and other problems.

A HACCP plan will regulate the working process. The employees will know how to deal with their tasks correctly and how to reach the highest quality of the product.

A HACCP plan saves you money. If your production is safe and compliant, you reduce the risk of recalls, losing customers, reputation problems, and dealing with even more severe issues. Consequently, you save money, reduce waste, and enhance efficiency.

What happens when a company demonstrates its commitment to food safety? They attract more customers, partners, and investors and become a strong competitor in the market. Also, HACCP facilitates access to export markets that often require a HACCP certification.

Once you implement your HACCP plan, you will constantly work on its improvement as it requires regular updates. The more you improve your HACCP plan, the safer and higher quality your product is.

Another important aspect is that a HACCP plan is essential to different 3rd party audits like SQF, BRC, and others. If you want to pass any of the GFSI-recognized certifications, you won’t move further without a HACCP plan.

Overall, a HACCP plan can only benefit your company and ensure many prospects for your business in the long run.

How to Create a HACCP Plan?

Now you are about to learn how to develop a comprehensive Hazard Analysis Critical Control Points (HACCP) plan with this clear, sequential approach. Ensure food safety by identifying potential hazards, establishing critical control points, and implementing effective monitoring procedures.

Assemble Your HACCP Team

You need staff educated in HACCP principles to build and execute your HACCP plan. The staff you choose for this first HACCP plan step need to have technical knowledge of your food preparation or production and of the chemical, biological, and physical hazards present at your facility or at your restaurant.

With FoodReady’s Enterprise solution, we can create your HACCP plan for you and help you set up your HACCP software at your business. If you need our HACCP consultant to visit your facility we can also arrange a site visit for an extra charge.

Describe Your Product, Intended Consumer, and Distribution

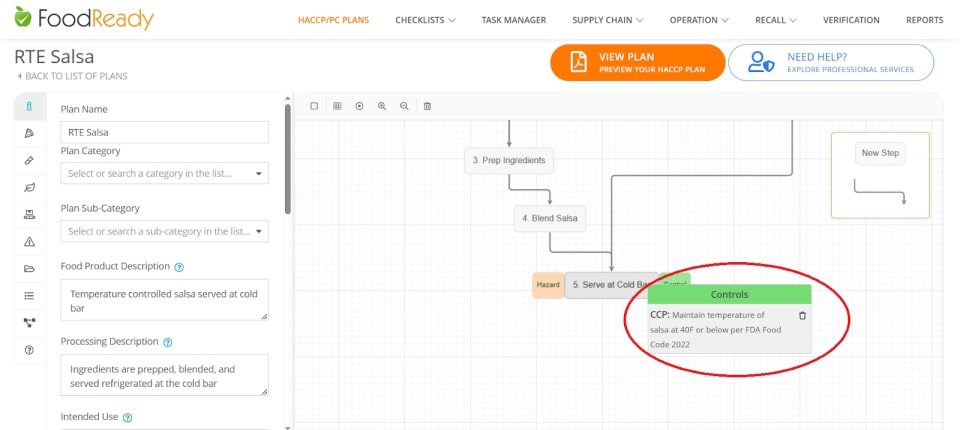

For demonstration purposes, our product is ready-to-eat salsa.

- Product Description – Ready-to-eat unpasteurized tomato-based salsa. The salsa will be stored in cold cases and refrigerated display cases.

- Intended Consumer – Our consumer is likely between the ages of 2-70. It is unknown if our consumer is of robust or fragile health. Our product will be sold at convenience stores, delis, and grocery stores.

- Distribution – Our salsa will be shipped to retailers in refrigerated trucks.

Describe Your Food Process

- Pre-approve and verify suppliers.

- Receive ingredients from suppliers. Check delivery trucks and supplies for contamination, dirt, insects, spoilage, and general condition.

- Perishable ingredients are put into cold storage. Shelf-stable ingredients are stored in the warehouse.

- Prepare Salsa (chopping, mixing, etc.)

- Package and Label Salsa

- Pack salsa into boxes

- Boxes are put into cold storage.

- Load boxes onto refrigerated trucks.

(Most processes will also include various sanitation and standard operating procedures)

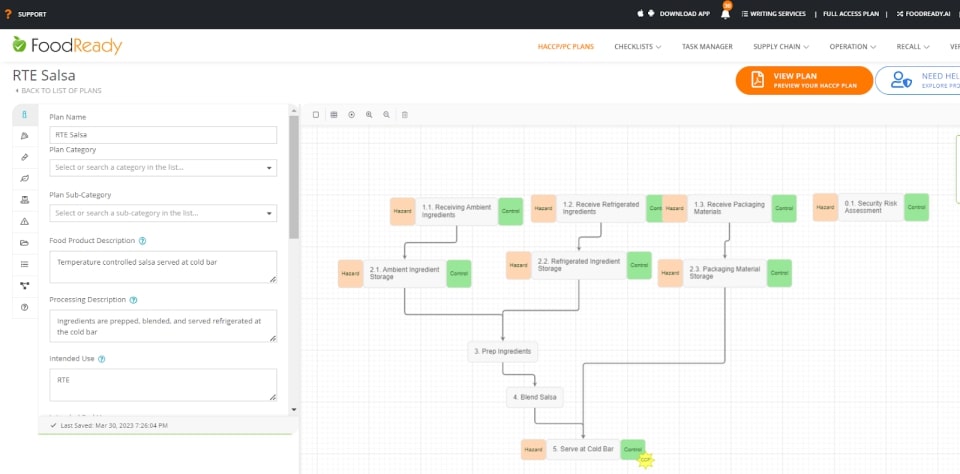

Develop a Simple Flow Chart of Your Food Process

This should illustrate a clear and simple outline of every step from receiving the ingredients to distributing the finished product.

FoodReady food safety software has a drag-and-drop HACCP flow chart builder and a library of over seventy Food Safety / HACCP plan examples for GFSI, SQF, GMP, USDA, FDA, Local Health, and Retail compliance.

Simply choose the template that most closely resembles your food product and customize the HACCP steps to your process.

We have a video knowledge base to help you learn this process, or you can hire one of FoodReady’s food safety consultants like SQF Consultant, GMP Consultant, GFSI Consultant, FDA Consultant to build your HACCP plan for you.

Analyze the Flow Chart With Your HACCP Team

Your HACCP team then needs to verify that the HACCP flow chart you created is correct and that there are no missing steps in your food production process. Any corrections to your process are made at this time before implementation.

Once you finish these steps, you have to apply the 7 HACCP principles.

Those will be the next steps in developing a HACCP plan.

BUILD A HACCP PLAN IN MINUTES

Streamline your food safety compliance with FoodReady’s drag-and-drop HACCP Builder.

The 7 Principles of HACCP

These seven HACCP principles are the cornerstone of a HACCP plan and must be completed correctly.

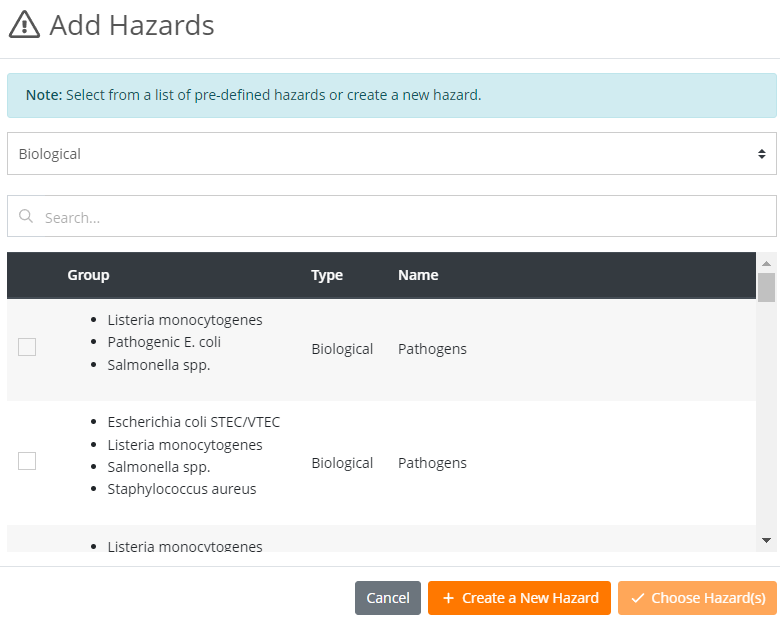

HACCP Principle #1 – Perform a Hazard Analysis

The hazard analysis is the step where the HACCP team scrutinizes the production process and documents where and how any hazards can be introduced to the food process. Food safety hazards are either biological, chemical, or physical. HACCP principle #1 is perhaps the most important step in writing a HACCP plan because this is the step that identifies food hazards that can make your customer sick.

For instance, if you are working with raw meat there are biological hazards like E. coli and Salmonella bacteria that can contaminate the meat. Any surface or equipment that comes into contact with raw meat could have these biological hazards on it and needs to be controlled to keep your customers from getting food poisoning.

Machinery used at certain points of the process could introduce a physical hazard like metal shards which pose a danger to your customer and must be addressed as a hazard in your HACCP plan.

Allergens, such as shellfish, fish, peanuts, tree nuts, soy, sesame, dairy wheat, and eggs are a significant food hazard.

Any food allergen contained in your product must be included on the food label, so the consumer can protect themselves if they have an intolerance or allergy to an ingredient.

Steps in your food process that could introduce allergens need to be noted. Allergens need to be carefully stored and used so they do not cause cross-contamination.

Any step in your process that introduces chemicals (such as equipment sanitizer) to the process or machinery needs to be noted.

In the hazard analysis, your entire process must be evaluated from the receiving of the ingredients to the delivery to your customer.

To ensure the safety of the ingredients you receive you need to make sure your suppliers have their own functioning food safety system like a HACCP, PC, or GMP certification.

Having pre-qualified suppliers or ingredients and packaging is a PRP (pre-requisite program) that most manufacturers have in place.

A PRP is any program that you have to help ensure the safety of your product before your process begins.

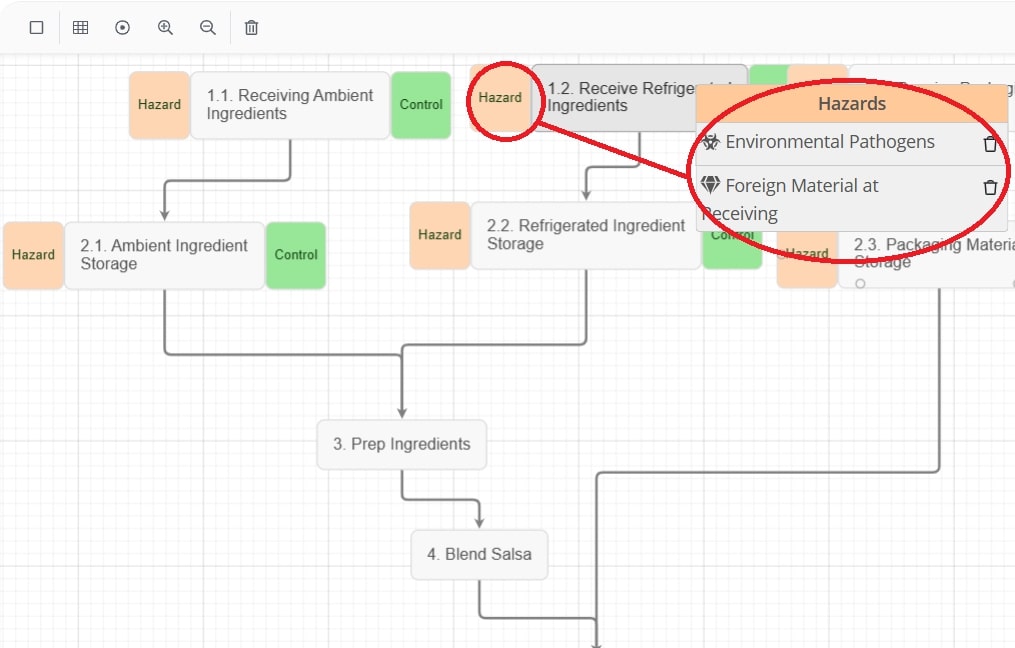

After the hazards are identified the HACCP team must evaluate the severity of each possible hazard, how much it could harm the consumer, and the likelihood of this hazard occurring.

For instance, if Listeria is found in baby formula it’s an enormous risk because of the fragility of the population that consumes baby formula. This is an example of a food safety problem that causes a very severe hazard to a sensitive population.

As for the likelihood of occurrence, it’s much more likely that a product like packaged lettuce which has a lot of moisture would have more bacterial growth, than a product that is pre-cooked and then frozen.

Once the list of hazards is made you must list the “controls” you can use to eliminate, or reduce the hazards.

For example, if your product is packaged lettuce, the lettuce would be washed in a solution to control the growth of bacteria. If your product is pre-cooked frozen hamburger patties, the patties would be cooked to a specific temperature for a certain amount of time to kill pathogenic bacteria which could be harmful to your customers.

After all the hazards are identified, apply them to your flow chart at the appropriate steps.

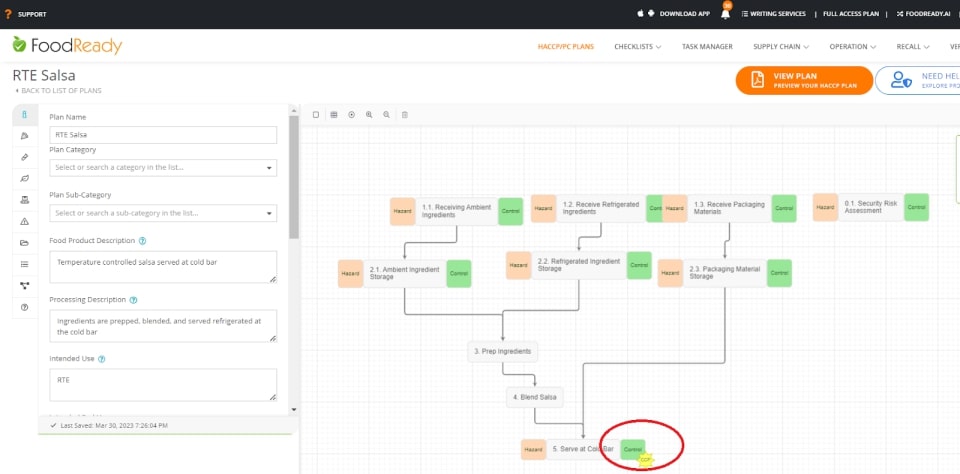

HACCP Principle #2 – Determine Critical Control Points

Now that you know which hazards could be the most detrimental to the health of your consumer and which are the most likely to occur, you need to determine at which point in your process you can control the hazard by eliminating it or reducing it to acceptable standards. These are called Critical Control Points.

In our example of ready-to-eat salsa, there is a CCP at the final step “serving at a cold bar”. If the temperature of the salsa rises above a certain level there is potential for biological pathogens to grow.

HACCP Principle #3 – Establish Critical Limits

Critical limits are the maximum and minimum levels needed to achieve control over the hazards at each CCP.

For instance, you may need to cook food to a specific temperature for a certain amount of time to kill biological pathogens. These parameters must be listed at each critical control point.

For example, salsa must be kept at or below a minimum temperature of 40℉ according to the FDA to control bacterial growth.

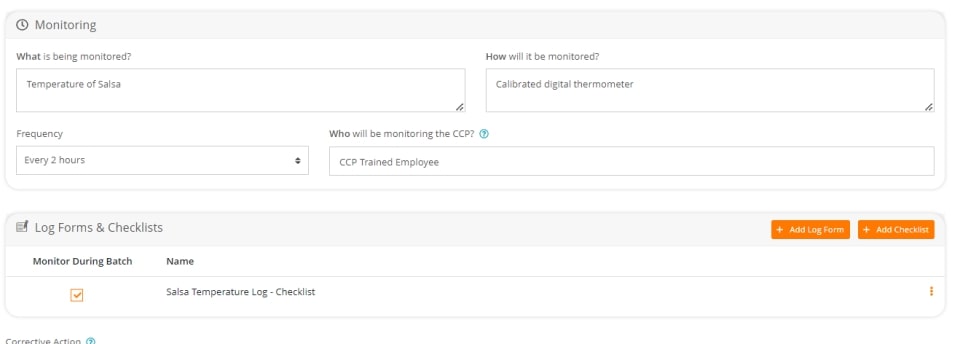

HACCP Principle #4 – Establish Monitoring Procedures

There must be a way to monitor that any hazards were controlled or stopped at the critical control point. Examples of monitoring could be logging times and temperatures needed to kill pathogens, swabbing for pathogen identification on sanitized equipment, testing the magnets used to detect metal in food to make sure they are working properly, and other measures.

As monitoring measures are performed, the staff responsible for monitoring must document and record their actions in monitoring logs. These monitoring logs must be maintained and available for retrieval for audit and inspection purposes.

HACCP Principle #5 – Establish Corrective Actions

This step is needed when a hazard is not properly controlled at the CCP.

For example, let’s say one of the HACCP team uses their Bluetooth thermometer and discovers that the salsa temperature is at 50℉ which is above the 40℉ maximum temperature. In this case, the corrective action would be to dispose of the salsa to prevent people from eating food that could have biological contamination.

HACCP Principle #6 – Establish Verification Procedures

Firstly, the initial HACCP plan must be verified for validity by HACCP-trained individuals. This is often done through a process called HACCP plan validation, which confirms that the control measures are scientifically sound and effective before implementation. For example; if cooking at a certain temperature is needed to kill pathogens, the oven temperature must be verified to make sure the proper temperature is obtained.

If the HACCP plan is verified and followed precisely, there is less need for corrective actions later on, resulting in safer food and a reduction in costs.

Verification procedures are in place so that when there is a failure in the HACCP system, compromised food can be targeted and dealt with in a manner that protects the consumer.

Additionally, the HACCP plan needs to be verified occasionally by an unbiased third-party auditor to ensure the HACCP is being followed correctly.

HACCP Principle #7- Establish Record Keeping and Documentation

An important part of a HACCP plan is making sure that all actions associated with the HACCP plan are recorded, and these documents are maintained and easily accessible.

This means that the HACCP plan itself, any corrective actions, monitoring, and verification are documented and retrievable for audits, recalls, food traceability, labeling, batch management, training logs, etc.

FDA’s Food Safety Modernization Act rule 204 is legislation that requires food manufacturers to have food recall plans in place, food traceability, and record keeping.

In the past, this meant having to maintain binders of documents to present during inspections and wade through when a recall needed to happen.FoodReady can build your HACCP plan, create your food safety system, and your process ready for any 3rd-party audit like SQF, BRC, GMP, GFSI, and the Costco Audit.

See How HACCP Plans Work in Real Food Businesses

Now that you’ve learned the seven principles of HACCP, you might be wondering how they come together in a real-world plan. Reviewing actual examples from a range of food categories can help clarify how critical control points, limits, monitoring procedures, and corrective actions are applied to different products and production methods.

Whether you work with animal proteins, packaged foods, ready-to-eat meals, or specialty items, these HACCP plan examples provide actionable insight into how the process works across diverse industries:

- Poultry Products HACCP Plan: Includes temperature control and pathogen management for raw and cooked chicken.

- Beef HACCP Plan: Focuses on E. coli reduction and sanitary handling during grinding or slicing.

- Sushi HACCP Plan: Highlights freezing for parasite control and cold chain integrity.

- Juice HACCP Plan: Addresses FDA Juice HACCP regulation and acidification procedures.

- Dairy HACCP Plan: Details pathogen control in pasteurization and storage of milk products.

- Sausage HACCP Plan: Manages thermal processing and cross-contamination risks in mixed-meat processing.

- Vegetables HACCP Plan: Includes washing steps, cold storage, and pathogen controls for fresh produce.

- Baked Goods HACCP Plan: Covers allergen controls and temperature-based baking steps.

- Coffee HACCP Plan: Focuses on dry processing, metal detection, and sanitation in roasting environments.

- Honey HACCP Plan: Addresses filtration, storage, and packaging hazards in natural sweetener processing.

- Distribution HACCP Plan: Useful for cold chain and temperature-controlled logistics.

- Chocolate HACCP Plan: Manages melting, tempering, and allergen segregation in confectionery.

- Restaurant & Catering HACCP Plan: Covers multi-ingredient prep and diverse critical points in foodservice settings.

- Reduced Oxygen Packaging (ROP) HACCP Plan: Focuses on anaerobic hazard prevention for vacuum-packaged foods.

- Cannabis Edibles HACCP Plan: Helps processors align with food safety and dosage control in infused products.

You can explore the full library of HACCP plan templates to find the one that best aligns with your product type and compliance goals. Each plan is customizable in the FoodReady HACCP builder, making it easy to adapt validated safety processes to your unique facility.

With a clearer understanding of how these principles work in action, you’re now ready to move forward with implementation, including building out your prerequisite programs, SOPs, and team training.

HACCP Plan Implementation

By implementing these stages, you and your team will write and incorporate a successful HACCP plan and achieve the highest possible level of food safety.

HACCP implementation is an intricate process and requires a lot of determination. The FDA provides the guidelines to help apply the HACCP principles and write a sophisticated HACCP plan.

Prerequisite Programs

Take care of the prerequisite programs. This is an essential requirement for creating a good HACCP plan. PRPs can create an acceptable environment and operating conditions for hazard-free, safe food production.

These environmental requirements can be indicated in state and local codes, standards, and guidelines like cGMP (Current Good Manufacturing Practices).

Prerequisite programs are developed and incorporated separately from the HACCP plan. However, some aspects can still be managed within the plan, for example, equipment maintenance and settings.

Prerequisite programs include an abundance of factors. Let’s look at some of them:

- Your facilities have to be built according to the principles of sanitary design.

- Your supplier must be reliable and have GMP and food safety programs.

- Maintain the equipment according to the established hygienic standards.

- Implement effective sanitation practices.

- The personal hygiene of employees has to be controlled.

- Traceability and recall procedures have to be well-organized, etc.

Standard Operating Procedures

One of the crucial prerequisites in HACCP implementation is the establishment, documentation, and execution of Standard Operating Procedures (SOP).

SOPs are detailed written guidelines indicating how to perform routine tasks that directly influence food safety.

Every Standard Operating Procedure should cover aspects like monitoring, documentation, corrective measures, and periodic assessment. Following SOPs will help in monitoring and preventing potential hazards.

Also, it is an effective way to keep the employees aware of how to perform their work.

These manuals have to be easy to read and regularly updated. They can be presented in different formats like steps, flowcharts, or diagrams.

FoodReady has everything you need for effective SOPs. Our AI SOP generator will easily create SOPs in no time. We will help keep your SOPs compliant and up-to-date as you’ll be able to track changes, control, and restore previous document versions.

HACCP Training for Employees

You must always know what you are dealing with. That’s why HACCP training for management and employees is a key to the successful HACCP plan.

The HACCP team must be well-educated and equipped to develop, implement, and update the plan. The training should include modules that cover the work with CCPs.

Once you and your team are educated enough to work with the HACCP system and the well-established prerequisite programs, you are ready to develop and implement the plan.

The HACCP system will remain effective if you stick to planned verification procedures and maintain the plan when required. But remember that the program won’t work unless the staff knows their role and responsibilities. Their input is invaluable.

Getting Your HACCP Certified

Once you have developed and implemented your HACCP system, you can try to get your HACCP plan certified.

A HACCP certification is a document that proves that you have developed a great HACCP plan and efficiently implemented it into your food safety management. If you are a food manufacturer or anyone who deals with food at different phases of the supply chain, HACCP certification will be an advantage.

The procedure and the preparation will include some of the steps you are already familiar with.

Work on perfecting your prerequisite programs. Then, develop, improve, and implement your HACCP plan.

Perform a Gap Analysis

Gap assessment will be an excellent preparation before the actual audit happens. Check all the processes to identify the gaps and areas for improvement so that you are entirely prepared for the inspection by the auditor. It’s always better to involve a third person who will be unbiased. That will help make the preparation more efficient.

As an example of preparation, you can conduct random temperature measurements and organize and check if the documents are easily retrievable, updated, and organized. Follow and include the latest food safety updates into your food safety management system.

Hire a 3rd-Party Auditor

Choose a verified third-party auditor. They are trained to thoroughly review the entire organization to confirm they adhere to the established food safety standards.

The HACCP certification routine can be time-consuming but definitely worth it. The audit itself will take approximately five days to complete. But the rest will depend on your certification goals, current workflow state, company’s size, etc.

Pass your HACCP Audit and maintain your result

It’s time to pass the HACCP audit and get certified. After successful certification, you are responsible for keeping your results, as a HACCP plan requires constant implementation and continuous improvement.

HACCP certificates need to be renewed within a certain period, which depends on the decision of the auditor you choose. In the next two years, you will have an announced or unannounced surveillance audit to verify if you still adhere to the HACCP standards.

You should also know that you risk revoking your certification if your company breaches the HACCP requirements.

In general, once you get HACCP certified, you must be responsible enough to improve your food safety and maintain your achievements.

Don’t forget that our HACCP consultants can help you get HACCP certified in a quick and easy way.

Common Mistakes When Working With the HACCP Plan

When it comes to HACCP, the process can be challenging, making it essential to recognize and avoid common mistakes.

First and foremost, generalized and irregular checkups can pose a problem. Various processes and facilities can hide different hazards. It is essential to check everything in detail and constantly so you maintain a steady checking routine. But remember that everything has to be in moderation; overly simple or intricate reviews can both be harmful.

Companies need to pay attention to prerequisite programs and prioritize training and preventative maintenance, so they can keep on top of hazards before they are introduced into the production process.

Another problem is neglecting reviews. They are usually associated with the audits; however, the HACCP plan must also be reviewed in other cases. For instance, when there are changes in the legislation, or you modify a recipe.

In general, ignoring or underestimating some of the compulsory steps or prerequisite programs can lead to issues with developing and implementing the HACCP system into the business.

FoodReady software and consulting will help you do everything right the first time.

See how our customers have flourished with our HACCP and 3rd-party audit help.

FoodReady will assist you with your HACCP Plan

FoodReady strives to help food companies manage food safety and digitize food safety compliance.

Our software has a HACCP builder with over eighty customizable HACCP templates to fit your business needs.

Make your quality and operational tracking tasks more efficient and optimized using FoodReady’s task manager or the user-friendly “drag-and-drop” checklist builder. This simplifies the transition for organizations seeking to replace their manual spreadsheet systems.

Also, you will track biological, physical, and chemical hazards in a database, as well as work with CCP logs with Bluetooth thermometer integration.

With FoodReady, you will feel confident about traceability and recall, monitoring, correction, verification procedures, and other significant steps needed for your HACCP plan.

We do offer consulting services as well, and our HACCP consultants will gladly assist you.

FAQs

Kill steps are those that you need to do to eliminate the bacteria. These can be cooking, freezing, pasteurization, and others. Read our guide to learn more about kill step in the HACCP plan.

Implementing HACCP can be an intricate, demanding, time, and money-consuming process. However, if you make sure your company can handle that, this is a worthy investment.

No, HACCP can fit other industries apart from food and beverage. For example, it can be cosmetics or pharmaceuticals.

Apart from the primary rules of HACCP, you should also learn how to align with regional standards, customize plans, and train your staff based on regional peculiarities.

Don’t forget about risk assessment to discover potential risks. Follow the international guidelines like those established in Codex Alimentarius.

Your HACCP plan should be reviewed whenever there is a change in your process, when there is a trend in poor food safety outcomes, and also periodically, some companies review their HACCP plan annually and others review their plans more frequently.

A digital HACCP system works much more efficiently for many reasons:

First and foremost, who wants to keep binders and binders full of papers that have to be waded through. A digital cloud based system removes the onus of the room full of papers.

Second, employees can document their actions in FoodReady’s mobile app which will help keep them compliant.

Third, you can take and log photos for visual verification, link to a Bluetooth thermometer for temperature controls.

Fourth, you can easily share your logs with inspectors.

Fifth, you can easily edit your HACCP when changes occur.

Sixth, your HACCP plan also links to your batch management, your supply of ingredients, your recall plan, etc. FoodReady is your food safety solution.

FoodReady’s HACCP writers are certified and have years of real world HACCP and food safety experience. We use our software to write your HACCP plan, where you can record and keep any associated SOPs, PCs, time and temperature logs, etc.