Foodborne illnesses affect 600 million people annually and cause 420,000 deaths worldwide. Cross-contamination is a significant cause; potential contamination is observed in 63% of restaurants. According to a 2023 study published in the Journal of Food Protection by Hoover et al. (DOI: 10.1016/j.jfp.2023.100182), bare-hand or dirty glove contact with ready-to-eat food occurs in 36% of food operations.

In this case, stand-up training refers to taking initiatives to uphold and improve the food safety culture in a manufacturing environment. It implies that food handlers and staff members take action against non-compliance in the food safety system and food quality culture, and that risk is mitigated on all levels at all times. Food handlers can achieve successful food safety stand-up training by adopting the important aspects in food manufacturing discussed below:

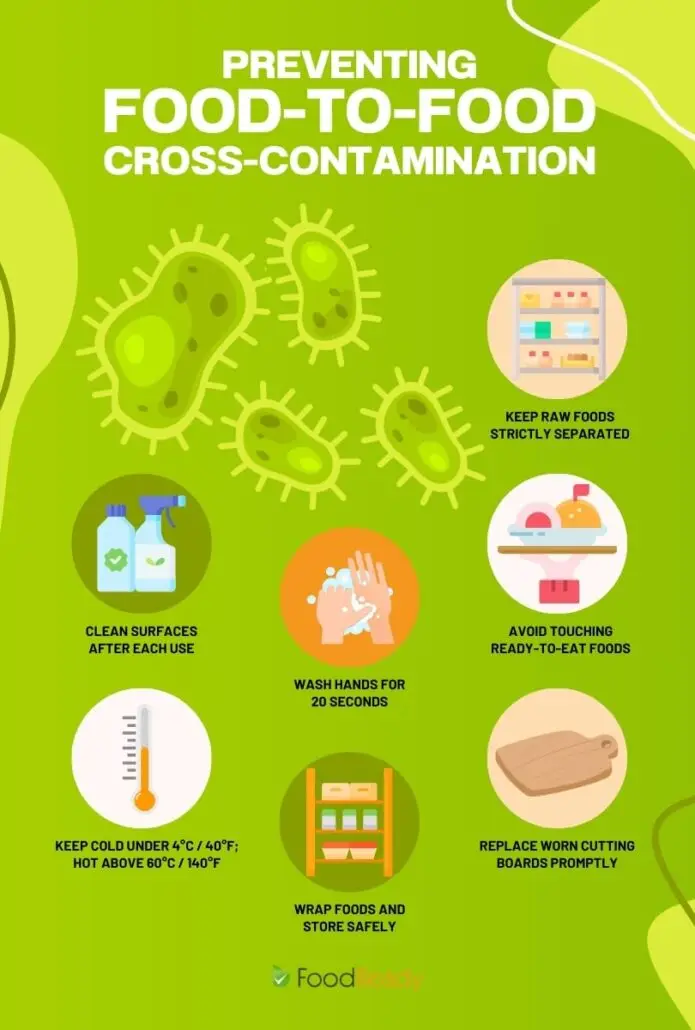

How to Effectively Prevent Food-to-Food Cross Contamination?

To prevent food-to-food cross-contamination, separation and hygiene must be prioritized.

Clear separation between raw and ready-to-eat foods during all stages of food handling, from delivery and storage to preparation and serving, is paramount and non-negotiable!

This includes using separate equipment, utensils, and work surfaces and practicing proper handwashing and sanitization techniques. Although repetitive and may seem monotonous, these practices can save our food businesses from tonnes of brand damage, including frustrated customers, which no one wants.

So, what points can we use for training on preventing food-to-food cross-contamination?

To begin with, what is cross-contamination? It is the transfer of harmful microorganisms, such as bacteria, viruses, and parasites, from one food to another. It can happen directly through physical contact between foods or indirectly through contaminated hands, utensils, or surfaces. Never forget that even the tiniest amount of contamination can cause foodborne illness, so one must be extra careful and have awareness at all times.

1. Raw vs. Ready-to-Eat

The separation of raw meats, poultry, and seafood from cooked and ready-to-eat foods is a cornerstone of safe food handling. Raw foods can harbour harmful bacteria, such as Salmonella, E. coli, and Campylobacter, which can easily contaminate ready-to-eat foods through direct contact or dripping fluids. This cross-contamination can lead to foodborne illness, with symptoms ranging from feeling slightly unwell to severe disease and ending up in the hospital!

Bacteria thrive and multiply rapidly in the “danger zone” temperatures between 4°C and 60°C (40°F and 140°F). Keeping foods out of this temperature range is highly recommended for food safety.

1. Storage

The first-in, first-out (FIFO) system is an effective food storage method that prevents food spoilage and waste. This ensures that older food items are used first. To implement FIFO, place items with earlier preparation or opening dates in front of or on top of those with later dates.

To prevent cross-contamination, always properly wrap or cover food items. Use plastic wrap, aluminum foil, airtight containers, or sealed bags. Also, apply clear and consistent labeling to all food items, including the ingredients’ names, batch numbers, production, and expiry dates. This practice also helps maintain food safety and prevents the use of expired ingredients.

3. Preparation

Always use separate cutting boards for raw foods and ready-to-eat foods. Clearly label each board with its designated use (e.g., “Raw Meat” or “Vegetables”). Colour-coded cutting boards work very well as a visual aid to quickly differentiate between boards and minimize the risk of error. For example, red cutting boards could be used for raw meat, green for vegetables, and yellow for poultry.

To maintain a safe food preparation environment, cutting boards should be regularly inspected for deep cuts or cracks that can harbor bacteria. Damaged cutting boards should be replaced promptly.

4. Hygiene

Emphasize thorough handwashing with soap and hot water for at least 20 seconds before, during, and after food handling, and especially after touching raw foods, using the restroom, or handling garbage.

Consider using disposable gloves when handling ready-to-eat foods, especially for high-risk foods like cooked meat and poultry. Change gloves frequently and wash your hands before putting on new gloves. Spray sanitizer onto your gloves at regular intervals whilst wearing and working with them.

5. Serving

Food servers should always avoid touching the eating and drinking surfaces of dishes and utensils, and never touch ready-to-eat foods with their bare hands. It is of the utmost importance to use tongs, serving utensils, or disposable gloves when handling ready-to-eat foods.

In self-service areas, separate utensils must be provided for each food item to prevent cross-contamination. Always ensure that utensils are clean and sanitized, and replace them frequently.

6. Temperature Control

We have discussed in detail the critical importance of ensuring that food is cooked to safe internal temperatures to kill harmful bacteria. Always use a calibrated and verified food thermometer to check internal temperatures, and follow recommended guidelines for different types of food. Remember to hold hot foods at or above 60°C and cold foods at or below 4°C to prevent bacterial growth.

7. Cleaning and Sanitation

Thoroughly cleaning and sanitizing all work surfaces and equipment after each use, especially after handling raw foods, should be second nature to food handlers. Always disassemble equipment for proper cleaning and sanitizing to get into the inner workings of the machinery.

After each use, wash all utensils with hot, soapy water and sanitize all work surfaces. This includes countertops, tables, and cutting boards. Between preparing different foods, this practice eliminates any lingering bacteria and prevents cross-contamination.

Disinfect surfaces and utensils with food-grade sanitizing solutions from an accredited supplier. Always follow the manufacturer’s instructions for proper dilution and contact time, and ensure food handlers are trained on dosage guidelines.

Conclusion

To conclude, what can we take away from this training session? Remember that by following these guidelines with your staff and food handlers, you can create a safe and organized food safety training protocol that vastly reduces the risk of cross-contamination and ensures the safety of your food products in a manufacturing environment or industrial kitchen setup. This increases customer satisfaction, credibility, and revenue for your food business.

Contact FoodReady now for a free demonstration of the various standard operating procedures, such as “Preventing Cross-Contamination During Storage and Preparation,” which are in our document library. This way, you can adapt these crucial SOPs into your food manufacturing or food processing facility with absolute ease and peace of mind.

FAQs

YES! Food poisoning is caused by the spread of bacteria in your food handling environment. This is called cross-contamination, and it occurs when bacteria are transferred from food to surfaces or from surfaces to food. Awareness of cross-contamination is especially critical when storing and preparing food.

Essentially, food-to-food cross-contamination is when harmful bacteria move from one food to another. It often happens when people handle raw meat and then touch foods that are ready to eat without washing their hands, use dirty aprons or towels when dealing with different foods, or don’t change gloves between handling various items.

To avoid cross-contamination, keep raw meat, chicken, and fish away from other foods. If possible, use different cutting boards for raw meats. Wash everything—cutting boards, knives, and counters—with hot, soapy water after handling raw meats. Don’t reuse raw meat packaging for other food. If we follow these tips to the tee, we mitigate the risk of food-to-food cross-contamination in leaps and bounds, for happy customers all round.