Ensuring safety to maintain quality and meet strict regulatory standards in the rapidly growing and highly regulated food and beverage production world is challenging. Companies rely on well-defined processes called Standard Operating Procedures (SOPs) to achieve these goals.

Executing SOPs is the cornerstone of excellence. It helps standardize operations, reduce errors, and ensure consistency across the organization. This guide explores the importance of SOPs in the food and beverage industry and provides insights into how to develop, implement, and optimize them for success.

What Are Standard Operating Procedures (SOPs)?

Standard operating procedures (SOPs) are detailed written instructions that describe the steps and operations required to perform tasks consistently and effectively. In the food and beverage manufacturing industry, effective SOPs cover everything from food safety procedures to cleaning, quality control inspection, equipment and personnel maintenance, and hygiene training.

Why Are SOPs Important in Food and Beverage Production?

Standard Operating Procedures (SOPs) play a foundational role in maintaining control, safety, and quality throughout every stage of food and beverage production.

Whether you’re operating a small facility or a large-scale manufacturing plant, SOPs are essential for streamlining operations and ensuring your team consistently follows best practices. Here are some of the key reasons why SOPs are critical in this industry:

Compliance With Regulatory Requirements: The food and beverage industry is highly regulated by the FDA, USDA, and international partners. SOPs help ensure that your products meet these regulatory requirements. This reduces the risk of violations, fines, and recalls.

Consistency and Quality Control: SOPs create an institution-wide system that ensures every product meets the same high standards. This consistent process is critical to maintaining customer satisfaction and building trust in the brand.

Food Safety: Food safety is paramount in this industry. SOP provides a structured approach to implementing Hazard Analysis and Critical Control Points (HACCP) to identify, monitor, and control safety hazards.

Operational Efficiency: Clear and well-documented SOPs help improve operations, reduce the chance of errors, and improve overall efficiency. They are a valuable training tool for new employees and serve as a reference guide for current staff.

Risk Mitigation: SOPs are essential for risk management. They help identify potential hazards in the construction process and identify corrective actions to eliminate or minimize them.

9 Elements of Effective SOPs in Food and Beverage Manufacturing

Developing a comprehensive and easy-to-follow SOP is crucial.

Here is some basic information to include in your SOP:

- Title and Purpose: Each SOP must have a clear title. The objective statement should describe the plan’s development and expected results.

- Scope: This section describes the scope of the SOP, including departments, roles, and procedures. It helps everyone understand who is responsible for what.

- Responsibilities: Clearly define the roles and responsibilities of each employee involved. This creates accountability and helps avoid confusion.

- Process: Every SOP has a step-by-step process at its heart. This section should be detailed and accessible. Each stage should be indicated by a number or bullet for clarity. Use flows and diagrams where necessary to increase understanding.

- Safety and Quality Control Measures: These include any safety precautions or quality control checks that must be performed during operations. This is especially important in the food and beverage industry, where safety and quality are paramount.

- Tools and Equipment Needed: List all tools, equipment, and supplies needed to perform the procedure. This ensures that employees are fully prepared before starting work.

- Documentation and Recordkeeping: Identify any documents that may be completed as part of a process, such as notes, audit plans, or reports. Proper recordkeeping is vital for compliance and accounting purposes.

- References: Include references to SOPs, rules, or other program guidelines. This information provides context and helps employees understand the big picture.

- Review and Change History: The SOP should be reviewed and updated frequently. It includes a date update and a summary of changes.

Developing SOPs for Food and Beverage Manufacturing

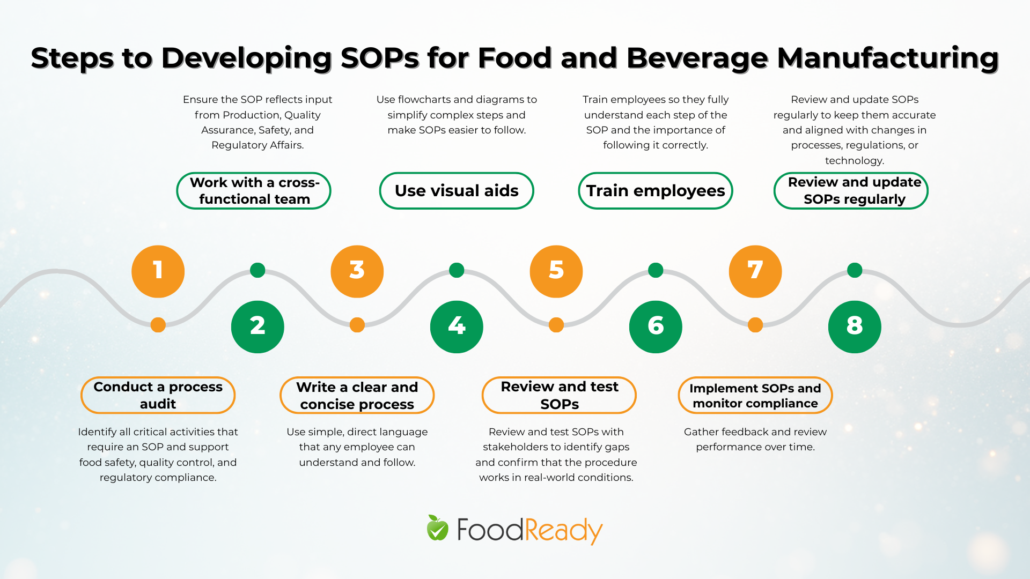

An effective SOP requires careful planning, teamwork, and attention to detail. Here’s a step-by-step guide to developing an SOP for your food and beverage manufacturing business:

1. Conduct a process audit

Start by taking a close look at your current processes. Identify critical activities that require an SOP and prioritize food safety quality control and compliance with regulations.

2. Work with cross-functional team

SOP development must be collaborative and involve input from cross-functional teams, including production, Quality Assurance, Safety, and Regulatory Affairs. It will ensure that the SOP covers and addresses all aspects of the process.

3. Write a clear and concise process

Clarity is essential when writing an SOP. Use language that is straightforward to understand. Avoid jargon and complicated terminology. The goal is to create a document that all employees can quickly follow, regardless of their level of expertise.

4. Use visual aids

Include audiovisual aids such as flowcharts and diagrams to complement written instructions. Visual tools help simplify processes and make SOPs more user-friendly.

5. Review and test SOPs

Before finalizing the SOP, review it with all relevant stakeholders and conduct testing. Real-world SOP testing helps identify gaps or ambiguities that need to be resolved.

6. Training employees

Once the SOP has been finalized, training employees on how to use it is essential. Organize training to guide employees through the steps and ensure they understand the importance of following it correctly.

7. Implementation and follow-up

Deploy SOPs and track their effectiveness over time. Gather employee feedback and conduct regular reviews to ensure the SOP is consistently followed and relevant.

8. Review and update regularly

SOPs should be reviewed and updated regularly to reflect process, regulatory, or technological changes. Schedule periodic reviews to ensure your SOPs remain current and effective.

Optimizing SOPs for Better Results

Creating an SOP is just the beginning. Consider the following optimization strategies to maximize performance.

1. Digitize your SOPs: In the digital age, many businesses are moving towards electronic SOPs. Digital SOPs are more accessible for updates, publishing, and access. It can be integrated with other digital tools, such as training modules, SOP software, and quality management systems.

2. Integrate continuous improvement practices: Adopt a culture of continuous improvement by regularly asking employees for feedback and including their suggestions in SOPs. This improves processes and performance and promotes employee participation and ownership.

3. Automate when possible: Look for opportunities to automate routine tasks within your SOP. Automation can reduce human error, improve performance, and help employees focus on more value-added activities.

4. Benefits of data analysis: Use data analytics to track the performance of your SOP. Analyze metrics such as error rates, production time, and compliance scores to identify areas for improvement. Data-driven insights can help you refine your SOP for better results.

5. Conduct training and retrain regularly: Regular training and retraining are essential to ensure employees are current on SOPs. Integrate SOP training into your onboarding process and take refresher courses periodically.

Using FoodReady for SOP Management

Standard operating procedures (SOPs) are critical to maintaining quality, consistency, and food and beverage production compliance. The right tools can significantly impact the effective management and implementation of SOPs.

FoodReady is a comprehensive food safety software solution designed to improve SOP management and help businesses achieve compliance with food safety standards such as HACCP, FSMA, and ISO 22000.

Key advantages of using FoodReady for SOP management:

- Custom SOP Templates: FoodReady offers customizable SOP templates specifically for food and beverage manufacturers. It allows you to create specific processes for your operations quickly.

- Centralized Document Management: Store, access, and update all your SOPs in one place. This ensures that your team is always working with the latest version.

- Automatic SOP Updates: Follow the latest food safety regulations by automatically updating SOPs as standards evolve.

- Employee Training and Monitoring: Set SOPs for employees, track training progress, and monitor compliance with built-in checklists and auditing tools.

Ready to standardize every step of your food safety process?

Standardize your workflows with simple, reliable SOPs.

Conclusion

Standard operating procedures (SOPs) are crucial tools for checking consistency, efficiency, and compliance within a manufacturing unit. By clearly outlining a step-by-step process, SOPs reduce errors, increase productivity, and provide a reliable framework for decision-making. They also serve as valuable assets for training new employees and maintaining high quality standards across teams and departments.

Creating an effective SOP requires collaboration. Regular review and a commitment to keeping requirements and regulations up to date. When well-developed and consistently implemented, SOPs can promote a culture of responsibility. Improve operations and support the organization’s long-term success

As your organization grows, investing in a clear, concise SOP will help simplify complex tasks and pay dividends by keeping everyone on the same page. After all, an SOP is more than just a document. They are at the heart of running an efficient, scalable, and flexible business.

FAQs

SOPs are designed to standardize processes, improve compliance with food safety assurances, and maintain consistent food and beverage production quality.

SOPs should be reviewed regularly, at least once a year, or whenever processes, rules, or technology change. Continuous improvement should be part of your SOP management strategy.

Developing an SOP must be a collaborative effort that combines input from multiple departments. A dedicated SOP team or coordinator can oversee the process, which includes production quality assurance, safety, and regulatory affairs.

Many businesses are shifting to digital SOPs, which provide benefits such as easier updates, better accessibility, and integration with other digital tools.

The SOP should include a title, purpose, scope, and responsibilities. The process should be explained step by step, including safety and quality measures, necessary equipment and materials, document requirements, reference documents, and editing history.

Manufacturing processes help ensure that SOPs meet regulatory standards set by agencies such as the FDA and USDA, providing a documented framework to meet regulatory compliance requirements. This reduces the risk of violations and fines.