A BRCGS (British Retail Consortium Global Standard) or BRC (British Retail Consortium) food safety audit is an internationally recognized evaluation process used to assess food safety systems across the supply chain.

BRC Certification is a GFSI (Global Food Safety Initiative) benchmarked standard.

The BRC Food Safety standard is used by food manufacturers, retailers and service providers around the world to assess their food safety management systems. By doing so, they’re able to demonstrate that they have an effective management system in place that ensures the safety of their products from source to shelf.

FoodReady BRC consultants and BRC software have all the components you need to get ready and stay ready for a BRC audit or GFSI certification. You can have a demonstration of our platform, have your questions answered and get pricing by scheduling a meeting here with one of our food safety experts.

What are the Benefits of Achieving BRC Certification?

Having a BRC certification means that your business is manufacturing safe quality food products you can be proud of. BRC certification is widely accepted and elevates your brand and because BRCGS certification is a GFSI benchmarked standard, you can sell your products at large retailers such as Whole Foods, Walmart and with an added addendum, you can sell at Costco as well. Learn more about the BRC certification benefits and how they open doors to major retail partnerships.

Here is a list of benefits of getting BRC-certified:

- Builds consumer trust by proving compliance with global food safety and quality standards.

- Recognized by major retailers and brand owners as a mark of excellence.

- Reduces the need for multiple customer audits, saving time and resources.

- Encourages senior management involvement and proactive issue resolution.

- Streamlines workflows and minimizes risks across food safety operations.

- Enhances competitiveness in both local and international markets.

- Strengthens brand reputation and supports long-term business success.

Preparing for a BRC audit is a daunting task. Make your work life a little easier by using FoodReady’s software and consulting services.

Check out our software and consulting features that will help you become BRC-certified.

What are the 12 Fundamental Requirements of the BRC Standard?

The 12 main requirements you must follow for the BRC standard are listed below:

- Your senior management is committed to continually improving safety and quality.

- You have a detailed food safety plan in place. (HACCP, SQF, GMP)

- You conduct regular internal audits.

- You manage suppliers of raw materials and packaging.

- You have corrective and preventive actions in place.

- You track and document ingredients from suppliers for traceability.

- Your factory layout, flow of processes and movement of staff must be sufficient to prevent the risk of product contamination and to comply with relevant legislation.

- You employ appropriate and effective hygiene regulations.

- You carefully separate and contain all known allergens.

- You provide a facility layout, floor plan, and organization that is in compliance with your food safety plan.

- All your food products are correctly labeled and packaged.

- You provide sufficient training for your employees that encompasses all areas of food production including but not limited to raw material handling, preparation, processing, packing and storage.

FoodReady is a food safety software and consulting company. Our software has an AI HACCP builder, food traceability, you can create your own checklists to manage your HACCP plan or track other items, ingredients, tasks, or events. With our Enterprise program you will have access to food safety quality assurance professionals who can help you with GFSI, SQF, GMP, SOP, BRC, CGMP, HACCP, USDA, FDA FSMA, gap analysis, or prepare for audits like the Costco audit, the Whole Foods, Publix, Kroger, Safeway, Meier, HEB and more.

BRC Certification Grades

BRC certification grades are an essential component of the certification process. They indicate the level of compliance a site has achieved against the BRC Global Standard for Food Safety.

Here’s how the BRCGS Culture Excellence Food Safety Culture Module Assessment grading system scores.

| Range Score | Grade | Basic Explanation |

|---|---|---|

| 90-100 | A+ | Very high scores above the industry norm indicate excellent satisfaction and agreement. |

| 85-89 | A | High scores, above the industry norm, showing general satisfaction and well-utilized tools and mechanisms. |

| 80-84 | B+ | High scores indicate general satisfaction and the presence of supportive tools, with room for enhancement. |

| 75-79 | B | Above industry norm, indicating satisfaction and the existence of supportive mechanisms. |

| 70-74 | C+ | Medium scores, close to the industry norm, show partial satisfaction with some practical tools. |

| 65-69 | C | Medium scores indicate partial satisfaction and some practical tools, but improvements are needed. |

| 60-64 | D+ | Low scores, below industry norm, showing general dissatisfaction and ineffective or inconsistent tools. |

| 55-59 | D | Low scores indicate dissatisfaction and low agreement levels, with necessary tool improvements. |

| 50-54 | E+ | Very low scores, well below the industry norm, indicate profound dissatisfaction and very low agreement. |

| 0-49 | E | Indicative of profound dissatisfaction, with a significant need for tools and support mechanisms changes. |

What is the Scope of BRC Certification?

BRC certification applies to a wide range of businesses and operations, each with unique requirements and specifications. From large-scale manufacturers to small-scale farmers, and from local retailers to global distributors, BRC offers standards that cater to the size, scale, and specialization of diverse entities within the food industry.

These standards also extend to companies involved in distribution, including storage, shipping, and logistics, ensuring product safety and compliance throughout the supply chain.

Furthermore, BRCGS standards are not confined by national borders or legal jurisdictions.

They are adaptable to various international arenas and are recognized by global regulators and multinational corporations.

Their universal applicability underscores the fundamental value they bring to the international food supply chain.

Certified Companies and Products

Achieving BRCGS certification places companies in the BRCGS directory, a comprehensive and publicly accessible database of certified businesses and their products.

This directory serves as a trusted resource for retailers, manufacturers, and customers seeking assurance that the food and consumer products they buy or supply meet the highest standards of safety and quality. Companies listed in the BRCGS directory can proudly display the BRCGS logo on their packaging and marketing materials, signaling their commitment to excellence in food safety and quality management.

The BRCGS certification scheme covers a broad range of food and consumer products, and is recognized by thousands of companies and retailers worldwide. This recognition not only enhances brand credibility but also facilitates access to new business opportunities and partnerships within the global food industry.

How to Get BRC Certified?

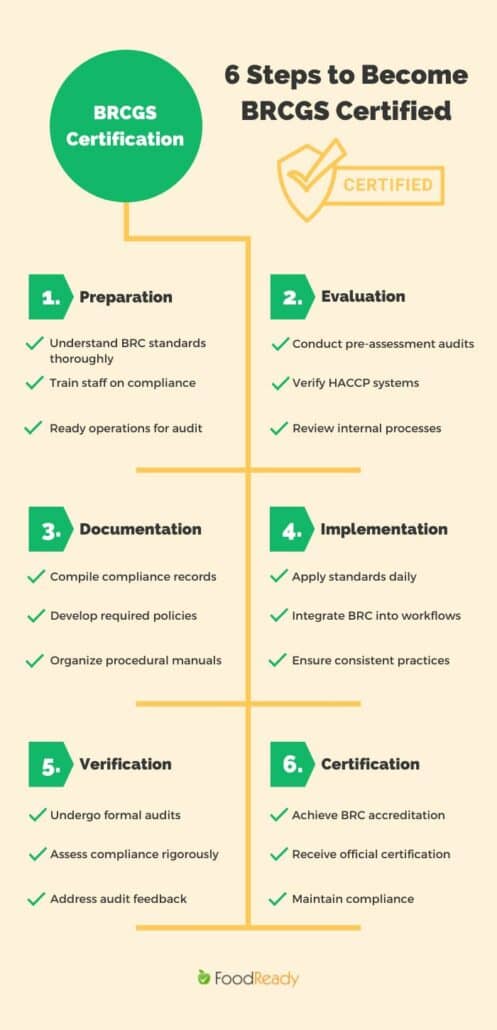

The process of BRC certification involves six steps:

- Preparation: The first step is to understand the BRC requirements and complete any necessary staff training.

- Evaluation: Engage in a pre-assessment, internal audits, and HACCP verification.

- Documentation: Develop and compile the required policies, procedures, and records.

- Implementation: Integrate the BRC standards into all your business processes.

- Verification: Undergo formal audits by accredited certification bodies.

- Certification: Upon successful auditing, you will receive BRC certification, which will be subject to surveillance and re-evaluation.

Obtaining BRC certification is both a process and a milestone. The last step involves an external audit by accredited BRC auditors, who evaluate the business’s systems, facilities, and practices against BRC’s meticulous criteria.

BRC Certification Costs

The costs of obtaining BRC certification can vary widely based on your organization’s size, the complexity of your operations, and the chosen certification body. You should budget for costs associated with initial certification, including preparation and training, as well as ongoing maintenance costs, including annual reviews and recertification audits.

Maintaining and Improving BRC Standards

Certification is just the beginning of a company’s BRC journey. Maintaining standards requires ongoing commitment and vigilance. Regular internal audits, training updates, and staying abreast of evolving BRC criteria are critical elements of post-certification compliance. Equally important is the ongoing development and continual enhancement of food safety management systems to ensure sustained compliance and proactive progress toward full BRCGS certification.

Maintaining and improving BRC standards is a dynamic process that necessitates adaptation to new information, technologies, and market trends. Companies must embed a culture of continuous learning and improvement to ensure their BRC certification remains a living testament to their commitment to food safety and quality.

Challenges and Solutions in BRC Implementation

The path to BRC certification is not without its obstacles.

Businesses often face logistical, operational, and cultural challenges during implementation.

However, proactive solutions can mitigate these challenges, such as investing in employee training, fostering a supportive organizational culture, and leveraging BRC software.

Adopting a systematic and strategic approach to BRC implementation is crucial. Best practices include breaking down the process into manageable steps, building cross-functional teams, and seeking external advice and support where necessary. Overcoming implementation challenges is a testament to a company’s resilience and resourcefulness, qualities underpinning the essence of BRC standards.

Partner Organisations in BRC Certification

BRCGS collaborates with a network of elite partner organisations to provide comprehensive support and resources for food manufacturers pursuing certification. These partnerships offer access to a wide range of training courses, industry events, and expert guidance, all designed to help companies implement effective food safety management systems and achieve BRCGS certification.

Partner organisations play a vital role in promoting the BRCGS certification scheme and supporting manufacturers through every step of the certification journey. By leveraging these partnerships, companies benefit from the latest industry knowledge, best practices, and practical tools needed to protect the global supply chain and ensure the safety of food products.

Together, BRCGS and its partner organisations are committed to connecting and protecting businesses, customers, and other stakeholders across the world, reinforcing the value of globally trusted certification programmes.

Our Food Safety and Quality Management Software features:

Food Safety Expert Consultants

- Staff trained in GFSI benchmarked standards like SQF, BRC, HACCP creation and certification.

- One of the company’s founders is a GFSI benchmarked standards auditor and food safety expert with 25 years of experience.

HACCP Builder

- 80+ HACCP / PCP Plan Templates.

- Biological / Chemical / Physical Hazards Database.

- Implement Critical Control Point (CCP) Logs with Bluetooth Thermometer Integration.

- Drag-drop flow chart builder.

Operation Checklists

- Easy ‘Drag-Drop’ Checklist Builder with Custom Controls such as Conditional If / Then Logic, Multi-Select Drop Downs, Max-Min Temperature and Numeric Values, and more.

- Replace Excel spreadsheets with “Grid View” sheets, which are available in the mobile app.

- Task Scheduling & Notifications.

- Shipping and Receiving Logs and Inspections for Traceability.

- Quality Control Signature Workflows for Deviations & Corrections.

Batch Management and Inventory Database

- Batch / Production Run Management With Associated CCP Logs and Quality & Food Safety Checklists.

- Recipe Formulation, Bill of Materials, and Lot Traceability Management.

- Track Quantity on Hand, Work in Progress, and minimum quantity alerts with Inventory Management.

- Purchase Order and Sales Order Management.

- Integration with Quickbooks™

Traceability and Recall

- Recall Plan & Mock Recall Management.

- Product Complaint Tracking.

- Receiving & Shipping Lot Traceability and Sales Order and Purchase Order Tracking.

- Receiving GS1 Barcode Scanning.

Automated Supplier Document Management

- Supplier Upload Portal

- Easily manage hundreds or thousands of required supplier documents in one place.

- Automatically emails suppliers with document requests.

- Save months of effort managing hundreds or thousands of files.

Monitoring and Verification

- Real-time list of CCP logs and checklists for Management Review.

- Generate Corrective Action Reports and CAPA Logs to address Deviations.

- Real-Time Notifications if Monitoring Limits are breached or additional reviews are needed.

- Pairable with Thermoworks bluetooth thermometer for temperature monitoring.

Environmental Monitoring

- Environmental Swabbing Documentation.

- Organize Areas, Zones, Locations, Indicators, Pathogens, and Testing Frequency.

- Testing Scheduler with Notifications and Reusable Templates.

- Integration with Alliant Food Safety Labs and other 3rd Party Laboratories.

Cloud Based System with Mobile App

- Real-time updates from employee’s mobile apps visible on the web system at any location.

- English and Spanish versions of the mobile app.

- Compatible with Mac and Android

Wrapping-up

For businesses seeking to secure a BRC certification, the effort and resources invested are not only measures of compliance but commitments to a better, safer, and more resilient food industry. The vitality of the global food market depends on such proactive initiatives, and BRC stands as a model worth emulating and exceeding.

FAQs

The latest BRC standard is Food Safety Issue 9. It was launched on August 1, 2022.

They are different. ISO covers any product, whereas BRC focuses on a specific range of fields.

BRC Certification typically requires an annual renewal through a re-audit process to ensure ongoing compliance with the BRC standards. This ensures that food safety management systems remain effective and up-to-date with any changes in the standard or industry practices.

Companies often face challenges such as understanding the specific requirements of the BRC standard, aligning their current practices with those standards, managing the documentation required for the audit, and ensuring that all staff are adequately trained and engaged in the process. Utilizing food safety software and consulting services can help address these challenges.

Yes, SMEs can achieve BRC Certification. The process involves developing and implementing a robust food safety management system that meets the BRC standards. SMEs may find it beneficial to leverage specialized software and consulting services to prepare for the certification process, ensuring they meet the necessary requirements without excessive overhead.

BRC certification can significantly benefit small-scale suppliers by enhancing their marketability to major retailers and manufacturers that require their suppliers to adhere to strict food safety standards. It also helps in improving their operational efficiencies and product quality.

Technology, particularly food safety and quality management software, plays a crucial role in maintaining BRC Certification compliance. It helps in streamlining the documentation process, ensuring real-time monitoring and control over food safety processes, managing supplier compliance, and facilitating efficient and effective internal and external audits. Tools like HACCP builders, CCP logs, and traceability systems are essential for achieving and maintaining compliance.

It is recommended that certified companies update their training and knowledge annually to stay aligned with any updates or changes in BRC standards.

Companies in non-English speaking countries can pursue BRC certification by working with local certification bodies that provide auditors fluent in the local language. BRC provides documentation and standards translated into several languages to accommodate non-English speakers.

Yes, while BRC initially focused on the food industry, it has expanded to include standards for packaging and packaging materials, storage and distribution, and agents and brokers, making it relevant for a broader range of industries.

Yes, BRC certification can be revoked if a company significantly fails to maintain the required standards during surveillance audits, if there’s evidence of a major food safety breach, or if the company refuses to comply with audit requirements.