Food safety and public health are top priorities for manufacturers, and a food safety plan can help protect consumers from foodborne illnesses and protect brand reputation.

Moreover, stringent regulations, such as the Food Safety Modernization Act (FSMA), require food businesses to develop a proactive approach to handling hazards rather than responding to them.

This is why domestic or foreign food manufacturing companies in the U.S. must have a written and implemented food safety plan. However, managing it can be overwhelming. This is where our guide comes in.

In this article, I will explain the role of a food safety plan. You will also learn the essential steps to creating one and how digital solutions can help you streamline food safety plan management.

Let’s dive in!

What Is a Food Safety Plan?

A food safety plan (FSP) is a set of written documents that outline the procedures and controls a food manufacturer, processor, distributor, or holder must follow to ensure product safety and prevent foodborne illnesses.

The FSP is based on a preventive approach and aims to identify, evaluate, and control potential hazards in food production. It incorporates HACCP (Hazard Analysis and Critical Control Points) principles while expanding them into a more comprehensive risk management framework.

A well-structured FSP covers the whole supply chain, from raw materials to distribution, protecting public health and preventing contaminated foods from reaching consumers.

What Are the Elements of a Food Safety Plan?

Below are the foundational elements of an effective FSP, enhanced with insights from industry best practices:

1. Hazard Analysis

- In-Depth Analysis: Review each stage of the production process for biological (e.g., Listeria, Salmonella), chemical (e.g., pesticide residues), physical (e.g., metal shavings), and radiological hazards.

- Collaborative Approach: Include production, quality assurance, and engineering personnel for a robust review.

- Continual Review: Especially critical when introducing new ingredients or updating processes.

Tip: Stay informed with the latest research and regulatory alerts on emerging hazards.

2. Preventive Controls

These include:

- Process controls like temperature, pH, and time.

- Food allergen controls for segregation and labeling.

- Sanitation controls for cleaning and personal hygiene.

- Supply-chain controls for ingredient testing and supplier verification.

Example: To prevent Salmonella in poultry, set a process control that ensures an internal cooking temperature of 165°F (73.9°C).

3. Determining Critical Control Points (CCPs)

- Detailed Mapping: Use flowcharts to trace every step in food production.

- Decision Trees: Apply decision-making tools to identify CCPs correctly.

- External Review: Consultants can help validate complex CCPs.

4. Establishing Critical Limits

- Scientific Basis: Use validated data, e.g., microbial inactivation parameters, to define safety thresholds.

- Regulatory Compliance: Follow FSMA and Codex standards.

Tip: Always document the rationale for each critical limit.

5. Monitoring Procedures

- Written Protocols: Define what, how, and how often to monitor.

- Digital Tools: Enhance accuracy and real-time tracking.

- Staff Training: Personnel should understand the gravity of their role.

6. Corrective Actions

- Scenario Planning: Prepare contingency responses (e.g., hold, test, recall).

- Documentation: Track the issue, root cause, and resolution.

- Real-World Example: If poultry wasn’t cooked to 165°F, discard the batch, calibrate thermometers, and retrain staff if needed.

7. Verification Procedures

- Internal Audits: Validate that procedures are followed as written.

- Third-Party Audits: Gain unbiased assessments.

- Equipment Testing: Regularly test and calibrate instruments.

8. Record-Keeping and Documentation

Maintain accessible and complete records for:

- Hazard analysis

- CCP monitoring

- Corrective actions

- Employee training

- Supplier verification

Tip: Use food safety software to store and retrieve these records during inspections or audits easily.

9. Training and Culture

- Ongoing Education: Regularly train on new regulations and tools.

- Open Culture: Encourage employees to report issues without fear.

10. Supply Chain Program

A verified supply chain program must be in place if a supplier manages a hazard. Ensure suppliers meet rigorous standards and document their preventive controls.

11. Recall Plan

A well-documented recall plan ensures rapid response and product traceability if a hazard reaches the market.

12. Continuous Improvement

- Audit trends: Use audit findings to refine controls.

- Customer Feedback: Identify overlooked issues.

- Tech Integration: Adopt new technologies to enhance safety.

Why Is a Food Safety Plan Important?

A food safety plan is an obligatory option for a reason. Food manufacturers must have it to ensure compliance, enhance productivity, and protect the consumers.

Here are the reasons why the FSP matters:

1. Regulatory Compliance

Having a food safety plan is an obligation. If you fall under the FSMA, your FSP must be written and implemented so you comply with the Human Food Rule. Additionally, maintaining accurate documentation for regulatory inspections guarantees that you are audit and inspection-ready.

2. Consumer Protection

FSP is critical to foodborne disease and cross-contamination prevention. Implementing the plan helps control hazards in food, protect public health, and prevent food safety incidents.3.

3. Waste Reduction

Following a food safety management plan will help minimize spoilage, contamination, and rejected batches. You’ll also avoid food waste and optimize resource utilization.

4. Brand Reputation

A food safety plan proves your accountability, maintains consumer trust, and reduces the risks of recalls and lawsuits. Altogether, it helps you build a firm brand name and avoid mistakes that can lead to loss of brand integrity.

What Is the Difference Between the HACCP Plan and the Food Safety Plan?

Although a food safety plan and a HACCP plan are similar, they have differences. HACCP plan can be a crucial element of a larger food safety plan. An FSP is broader and covers risk-based food safety management.

The FDA provided a comparison table analyzing both HACCP and Food Safety Plans:

| Element | HACCP Plan | Different in Food Safety Plan |

| Hazard Analysis | Biological, chemical,physical hazards | Chemical hazards include radiological hazards, consideration of economicallymotivated adulteration (21 CFR 117.130(b)(1)(ii)) |

| Preventive Controls | CCPs for processes | Process CCPs + controls at other points that are not CCPs (21 CFR 117.135(a)(2)) |

| Parameters and Values | Critical limits at CCPs | Process CCPs + controls at other points that are not CCPs (21 CFR 117.135(a)(2)) |

| Monitoring | Required for CCPs | Required as appropriate for preventivecontrols (21 CFR 117.145) |

| Corrective actions andCorrections | Corrective actions | Corrective actions or corrections as appropriate (21 CFR 117.150(a)) |

| Verification (includingvalidation) | For process controls | Verification as appropriate for all preventive controls; validation for process controls; supplier verificationrequired when the supplier controls a hazard (21 CFR 117.155, 117.160) |

| Records | For process controls | As appropriate for all preventive controls (21 CFR 117.190) |

| Recall Plan | Not required in the plan | Required when a hazard requiring preventive control is identified (21 CFR 117.139) |

How To Build a Food Safety Plan?

Creating a food safety plan may seem overwhelming initially, but breaking it down into structured steps makes it manageable and more effective. Each phase builds on the last, ensuring your plan is tailored to your facility’s unique processes, products, and risks.

Here’s a step-by-step guide to help you build a comprehensive and compliant FSP:

1. Assemble a Team

Start by gathering a team of experts from different departments. The FDA indicates that the FSP development must be overseen by a Preventive Controls Qualified Individual (PCQI). A PCQI is qualified to develop and implement a food safety system and may not be a company’s employee.

The assigned leader will guide the development and implementation of a food safety plan. They should have either job experience or complete FDA-approved training.

2. Define the Product

Establish and define relevant details about the food product. This will allow you to assess potential food safety hazards and establish safety controls.

For instance, you can define product characteristics such as name, ingredients, processing and packaging methods, storage conditions, shelf life, etc. You can also specify the target audience and how the product will be consumed (e.g., ready-to-eat foods).

3. Develop a Process Flow Diagram

Map out the entire production process, workplace setting, and other elements like processing steps, raw material receiving, storage, distribution, etc. Detailed visual representation like this will help implement efficient preventive controls.

The process flow diagram (PFD) shouldn’t be too professional and complex but must be verified with the production staff. Need help creating a PFD? Food safety software can help.

4. Conduct Hazard Analysis

Conducting a hazard analysis is crucial to identifying and evaluating potential food safety hazards. You must analyze every step of the food production process to check them for the hazard presence.

Generally, the steps you should take for analyzing hazards include listing all the processes, identifying potential hazards, assessing risks and their likelihood of happening, and determining preventive controls.

You should also include other hazards, such as radiological or allergens, in addition to physical, chemical, and biological hazards.

5. Establish Preventive Controls

Preventive controls are critical to eliminating and reducing food safety risks. Types of preventive controls include:

- Process controls. These operations (cooking, cooling, pH adjustments) remove a hazard or minimize it to an acceptable level.

- Food allergen controls – preventing cross-contact and implementing labeling.

- Sanitation controls – includes cleaning and hygiene.

- Supply-chain controls – ingredient testing, supplier approval, etc.

- Other controls.

For instance, concerning process controls, the safe cooking temperature for poultry to kill Salmonella must be 165°F (73.9°C). Allergen control will include separating gluten-free products from regular ones, and sanitation controls are about personal hygiene and separating raw and ready-to-eat foods.

6. Define Monitoring Procedures and Critical Limits

Set critical limits for each preventive control; these boundaries must not be exceeded to maintain food safety. Establish monitoring procedures that outline what will be measured, how, when, and by whom.For instance, concerning process controls, the safe cooking temperature for poultry to kill Salmonella must be 165°F (73.9°C). Allergen control will include separating gluten-free products from regular ones, and sanitation controls are about personal hygiene and separating raw and ready-to-eat foods.

7. Plan for Corrective Actions

You must develop a corrective action plan. In case of deviations from critical limits, taking corrective action helps prevent contaminated food from reaching your consumers.

The steps you must take in such a situation will be:

- Identifying the root cause.

- Immediate corrective action, such as discarding the food.

- Documenting the issue and how it was resolved.

- Review and improve preventive controls.

Corrective actions back up preventive controls, and updating them is crucial so the issue can be prevented earlier.

Imagine a scenario in which you didn’t cook the chicken to the required 165°F. In this case, you must identify the root cause—let it be equipment malfunction—and take corrective action—either recook the meat or discard the batch.

The next step would be to record the incident, noting the batch number, temperature readings, and actions taken. Then, you review and improve the preventive control (calibrate the thermometer or conduct equipment maintenance).

Here’s how corrective actions can be taken in a real-life situation.

8. Create Verification Procedures

Verification confirms that your food safety plan is working as intended. Include activities such as:

- Internal audits

- Equipment calibration

- Microbiological testing

- Review of monitoring and corrective action records

Consider periodic third-party audits for an unbiased review of your system.

9. Record-keeping and Documentation

Proper recordkeeping is necessary for food safety plan documents and regulatory compliance, traceability, and audits. Any changes, improvements, and revisions to the food safety plan should be documented.

Here are the records you must maintain:

- Hazard analysis reports

- CCP monitoring logs

- Supplier verification records

- Corrective actions

- Employee training records.

There’s also no established format for a food safety plan in the U.S. You can approve the format with local food regulatory authorities.

10. Supply Chain Program

According to the FDA’s requirements for a food safety plan, food manufacturers must have a risk-based supply chain program if the hazard analysis identifies a hazard that requires preventive control, and it will be applied in the facility’s supply chain.

However, you don’t need that program if you manage the hazard in your facility or it is controlled by a subsequent entity (such as another processor).

The supply chain program ensures you control the hazards associated with raw materials and ingredients before they enter production. Especially if risks are not fully managed within the facility.

11. Recall Plan

Even with the best controls, issues can arise. A written recall plan helps you quickly and effectively remove unsafe products from the market. It should include:

- Roles and responsibilities

- Notification procedures

- Traceability systems

- Communication templates

12. Continuous Improvement

In our blogs, we often mention the importance of continuous improvement. FSP is not a static document; it requires constant improvement to stay effective and compliant.

By regularly reviewing audit findings, monitoring data, and taking corrective actions, you can identify new potential risks before they occur. Your commitment to continual improvement strengthens food safety, protects consumer health and your reputation, and optimizes operations.

Review it at least annually or any time you:

- Change ingredients, equipment, or suppliers

- Experience a food safety incident or nonconformance

- Face new regulatory requirements

Ongoing review and improvement ensure your plan remains effective, compliant, and reflects your current operations.

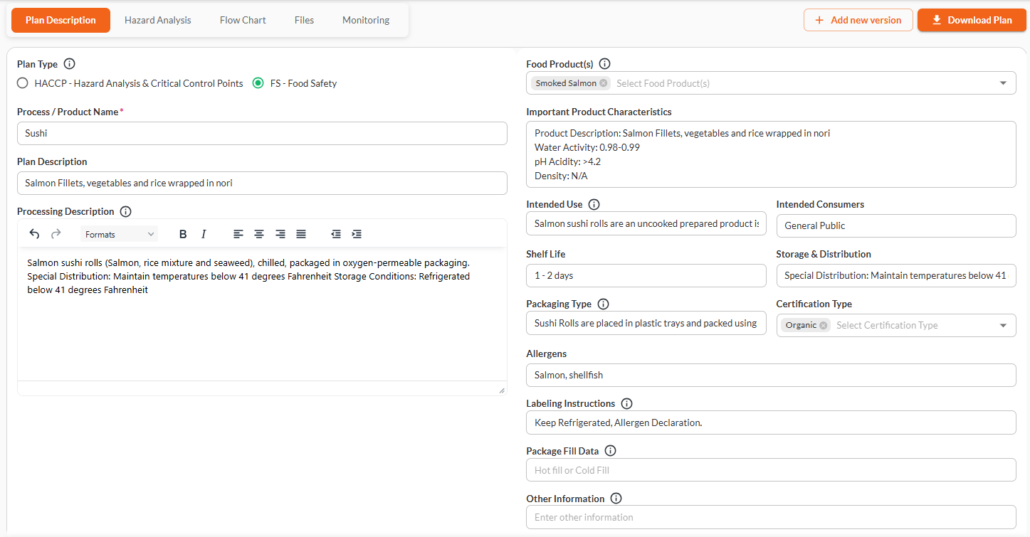

To illustrate how a food safety plan comes together in a real-world setting, the image above shows an example of a digital food safety plan created directly within the FoodReady platform. This sample plan outlines key elements such as product description, intended use, consumer group, shelf life, storage conditions, allergens, packaging, and processing details, all structured in a way that supports FSMA compliance, HACCP alignment, and audit readiness. By centralizing this information in a single system, food businesses can standardize documentation, improve accuracy, and maintain clear visibility across every component of their food safety plan.

When Do You Need To Update Your Food Safety Plan?

The time you need to update your food safety plan depends on different factors. Here are the cases when you should review and change your food safety plan:

1. Annual update

First, you must update the plan annually, even if no significant changes happen. A regular update keeps you compliant and up-to-date. Yearly updates can be based on industry trends, company growth, regulatory changes, etc.

2. When regulatory requirements update

The food safety industry is dynamic. Laws and standards, such as FSMA, HACCP, GFSI, and others, can change and emerge quickly. If you are subject to a new or updated rule, you should review your food safety plan to reflect the changes and stay compliant.

3. When you add new ingredients, recipes, or suppliers

Adding or modifying ingredients can lead to new potential hazards, so your task is to update the plan according to the modification.

4. When installing new equipment or changing the processes

The plan must reflect modifications to production lines and installations of new equipment, as these events can impact CPPs and preventive control and cause new contamination risks.

5. After a Food Safety Incident

In case of a recall, nonconformance, or foodborne illness outbreak, you must review and improve your food safety plan to prevent recurrence.

6. After an Audit

If an auditor finds gaps, you should address nonconformances in your food safety plan and review it. Also, you must update the plan if an internal audit reveals an issue.

Overall, apart from regular annual updates, the food safety plan must be reviewed and updated after each change, nonconformance, or improvement in the processes.

Extra Tips for Efficient Food Safety Plan

- Use Software: Tools like FoodReady automate hazard analysis, monitoring, reporting, and recalls.

- Simplify Your Format: Use visuals and flowcharts for easy understanding.

- Invest in Staff: Trained teams execute plans more reliably.

- Stay Informed: Join food safety networks or subscribe to regulatory bulletins.

Write Your Food Safety Plan With a Digital Solution

Creating an effective food safety plan can be overwhelming, and you might need help to manage it in the context of evolving regulations and extensive documentation requirements.

With FoodReady AI food safety management software, you can digitize your paper-based records and spreadsheets and streamline food safety compliance. Our platform is a perfect solution for automating and managing hazard analysis, monitoring preventive measures and critical control points (CCPs), building a recall plan, generating reports, and implementing corrective actions—each food safety plan component in one centralized platform.

We offer real-time monitoring, automatic alerts, and seamless audits so you can ensure FSMA, HACCP, and GFSI compliance without extra stress.

Don’t let manual processes slow you down, and benefit from the power of automation. Just like Eurobake. They addressed FoodReady to build out the food safety / HACCP plans for all their products, along with the necessary SOPs (Standard Operating Procedures) and essential checklists.

It helped them accelerate their audit processes and pass FDA, GMP, GFSI, and Costco audits with remarkable speed.

We also have a library of editable food safety/HACCP plan templates that can simplify the plan creation process.

If you want to learn more and are ready to start your food safety plan journey, book a demo with us to get started!

Struggling to keep up with food safety documentation and regulatory updates?

FoodReady streamlines hazard analysis, preventive controls, monitoring, and record-keeping with automation.

Conclusion

A food safety plan is a mandatory requirement for food businesses in the U.S. Most importantly, it demonstrates your proactive approach to preventing food safety hazards and foodborne illnesses. It will also help you protect your reputation and reduce food waste.

You must ensure your plan has essential components, including hazard analysis, preventive controls, corrective actions, monitoring and verification, recall plan, etc. Also, remember to assemble a responsible team, define the product, and create a process flow diagram in advance.

Here you are; your plan is ready, but now your task is updating it. Continuous improvement is crucial; you must change your plan annually or whenever the changes happen.

A food safety plan is complex, but you can handle it, especially if you invest in a food safety software solution like FoodReady. We offer various tools to help you write and manage a food safety plan—contact us to learn more!

FAQs

Overall, all food safety plan components are valuable and play an equal role in its effectiveness.

A food safety plan is required for all food businesses in the U.S.

Food safety plans can be categorized differently based on regulatory requirements and industry standards, such as a HACCP plan, GMP plan, allergen control plan, etc. We can also differentiate between process-based and recipe-based plans.

Process-based food safety plans are best when similar products share the same processes.

Manufacturers working with diverse products with unique ingredients and processing methods will benefit from recipe-based plans.

Inadequate hazard analysis, poor documentation, lack of employee training, failure to update the plan, and neglect of verification procedures are common mistakes. Businesses should also avoid overcomplicating processes or ignoring regulatory requirements, which can cause compliance issues and increased food safety risks.

Businesses can conduct routine audits, employee training assessments, and monitoring procedures. You can also validate your plan through testing, scientific studies, and real-world data analysis.

Failure to maintain a compliant food safety plan can lead to higher food safety risks, operational disruptions, reputational damage, and loss of customer trust. You can also face product recalls, regulatory penalties, and legal liabilities.

Continuous improvement can be achieved through implementing feedback mechanisms, staying open to adopting new technologies, and regularly reviewing the FSP for updates and improvements to adapt to new challenges and regulations.

Technology plays a crucial role in enhancing the effectiveness of an FSP by providing tools for better hazard analysis, real-time monitoring of critical control points, and streamlined record-keeping. Implementing software solutions for food safety management can automate many processes, improve accuracy, and facilitate quicker responses to potential safety issues.