Unfortunately, many foodborne diseases are caused by biologically contaminated food, and these are not rare cases. You can even find a list of foodborne illness outbreaks in the United States and see how many of them were caused by biohazards.

Biological hazards are hard to detect and pose a considerable challenge for food and beverage manufacturers responsible for their consumers’ health. Hazard control and mitigation require strict food safety measures.

We all need to know more about this, so let’s examine biological hazards in food, their types, sources, and handling methods.

Definition of Biological Hazards in Food

Biological hazards are one of the leading food safety hazards. These are pathogenic organisms like bacteria, viruses, parasites, or fungi that can contaminate food and cause foodborne illness or poisoning when consumed by a person. Biological hazards can contaminate food at any stage of food manufacturing.

Compared to physical hazards visible in food, biohazards are impossible for the human eye to notice. Hence, they require even more attention and a serious approach to their prevention and handling.

What Are the Types of Biological Hazards?

Biological hazards are generally divided into the following groups:

1. Bacteria

Salmonella, Campylobacter, E. coli, or Listeria are common bacteria that can contaminate food. Some are resistant to extreme temperatures and multiply quickly, while others are killed easily and don’t pose any significant harm to people.

2. Parasites

Parasites are mostly invisible organisms that contaminate food. They quickly enter the human body and survive by getting nutrients from their host. Protozoa, helminths, and ectoparasites are the most common types of parasites in food.

3. Viruses

Viruses are infectious agents that can survive in a host’s organism. They are highly resistant and can contaminate food at different supply chain stages, staying highly contagious. Viruses in the food industry are norovirus, hepatitis A, rotavirus, astrovirus, enterovirus, and adenovirus.

4. Fungi

Fungi include yeasts and molds. Some of the most common are Aspergillus sp. and Candida sp. Fungi can survive in different environments, from very acidic to very dry. Although many fungi are used to produce food like cheese, these microorganisms emit toxins and can cause severe intoxications and diseases.

Biological hazards can vary and, in many cases, are difficult or impossible to kill if they enter food. That’s why food manufacturers must prioritize preventing potential contamination.

Where Do Biological Hazards Come From?

Biological hazards can be found in different environments and organisms. For example, parasites can be in the soil or water, as well as in humans and animals. Bacteria live on moist surfaces and can be almost everywhere, including water, air, surfaces, animals, etc. Moist environments also promote fungi growth.

Let’s talk about the possible places where biological hazards are likely to exist.

1. Water and Soil

Beware of contaminated water. Water systems are one of the major ways biological hazards can reach food, as water is used for almost all food manufacturing and cooking processes. It must be adequately inspected and allowed for usage.

Soil can also pose risks as it can contain hazards and contaminate foods growing close to it. That’s why raw materials, like fruits and vegetables, must be washed.

2. People

People are natural habitats for biological hazards. Food handlers can transmit bacteria, viruses, or parasites and contaminate the food.

3. Infected Animals

Animals and pests can be both physical and biological hazards. They can carry bacteria, viruses, or parasites and contaminate food and surfaces through droppings, skin, saliva, etc.

4. Environment

Biological hazards are commonly found on surfaces. Improper cleaning and sanitation can allow bacteria or viruses to survive on food leftovers or moist surfaces.

How Do Biological Hazards Appear in Food?

Cross-Contamination and Environment

Cross-contamination is a widespread reason why biological hazards get into food. Also, the very food, its pH level, time, temperature, oxygen (or its absence), and moisture level can impact the development of bacteria, viruses, and other food hazards.

Improper Food Handling

Food handlers who carry biological hazards must adhere to strict hygiene rules and food handling techniques to prevent food contamination.

Supply Chain and Distribution

Contamination can happen at different supply chain stages, especially in international markets with other food safety practices and norms. Food distributors must also take care of transportation conditions. Just like in food storage or production, they can influence the spread of hazards such as fungi or bacteria.

What Risks Biological Hazards in Food Pose and What Can They Cause?

Biological hazards can cause either minor stomachaches or severe intoxication, leading to hospitalization and even death. Biological hazards can impact a lot of people, including children and pregnant women.

Some of the most common outcomes of biological hazard intoxication can be:

- Fatigue

- Abdominal Pain

- Fever

- Nausea

- Vomiting

- Diarrhea

- In severe cases, it can even lead to kidney failure or neurological disorders.

If contaminated food is found, it can lead to food recalls, loss of the manufacturer’s reputation, and legal issues. Contamination incidents can also cause changing trends in food consumption.

Which Food Safety Practices Prevent Biological Hazards?

Maintaining clean and sanitized food preparation areas, cooking food to the correct temperature, and thorough handwashing are all interconnected components of a strong food safety program designed to prevent biological hazards.

You can find additional guidance on Safe Food Handling as per FDA standards and how it aligns with current legislation.

So, let’s explore these food safety practices and their role in preventing biological hazards.

1. Effective Handwashing

Global food safety standards legally require proper hand hygiene in food manufacturing to prevent contamination.

Why should we wash our hands so frequently? Let’s look at the reasons below:

- Prevention of Foodborne Illness: Handwashing is essential to avoid the spread of pathogens that cause foodborne illnesses

- Compliance with Food Safety Regulations: Handwashing ensures adherence to food safety standards and regulations and reduces the risk of foodborne illness by removing harmful bacteria.

- Elimination of Cross-Contamination: Prevents cross-contamination between raw and ready-to-eat foods.

- Removal of Contaminants: Eliminates dirt, harmful bacteria, and allergens from hands.

Handwashing Assessment Criteria During Food Safety Audits

- Handwashing Facilities: Auditors will evaluate handwashing stations’ availability, proper installation, and upkeep.

- Handwashing Practices: Auditors will observe the frequency of handwashing by food handlers, if they are using the correct technique, and if they are using hand sanitizer.

- Documentation and Training: Auditors will review written handwashing policies and verify that staff have been trained on proper handwashing procedures.

- The results of not complying with handwashing requirements can be severe, including regulatory violations, failed audits, and product recalls.

Evaluation of Handwashing Stations

- Availability: Inspectors will confirm sufficient handwashing facilities exist in all food preparation and processing areas.

- Setup: They will verify that the stations are correctly installed and feature a dedicated handwashing sink, warm water supply, soap dispensers, and hand drying facilities like paper towels or air dryers.

- Upkeep: Auditors will check for evidence of proper maintenance, including clean basins, working faucets, and adequate supplies of soap and paper towels.

Observing Handwashing Procedures

- Frequency: Inspectors will note how often food workers wash their hands, especially after activities that could cause contamination, such as using restrooms, handling raw ingredients, or touching surfaces.

- Technique: They will assess whether personnel are washing their hands effectively, which includes using warm water, applying soap, scrubbing thoroughly for at least 20 seconds, rinsing, and drying off.

- Hand Sanitizer Usage: While not a substitute for washing, auditors may also evaluate hand sanitizers when appropriate.

Records and Instructions

- Handwashing Guidelines: Auditors will review documented handwashing policies that detail the required steps and frequency.

- Staff Education: They will confirm that food handlers have received training on proper handwashing methods and protocols.

What happens when we don’t follow these rules? Consequences are dire and are as follows:

- Regulatory Violations: Failure to adhere to handwashing standards can result in significant regulatory violations and a failing score on food safety inspections.

- Product Recalls: Insufficient handwashing can lead to food safety issues, potentially causing product recalls and damaging the company’s reputation.

2. Cooking Food to a Safe Temperature

Cooking food to the correct temperature is paramount in eliminating dangerous bacteria and preventing foodborne illnesses. Food must be cooked to a safe core temperature and then kept stable to prevent bacteria from growing. This involves checking the temperature of the food while it is being cooked and also while it is being held and cooled.

The internal temperature of food is the most accurate way to measure safety. Different foods with different minimum internal temperatures are considered safe, as they eliminate harmful microbes.

For instance, whole cuts of beef and lamb require at least 145°F(63°C), while ground meats and poultry need 160°F(71°C) and 165°F(74°C), respectively. Seafood also has its own specific required cooking temperatures.

- Maintaining Safe Holding Temperatures:

- The “danger zone” for bacterial growth ranges from 40°F (4°C) and 140°F (60°C).

- Hot food must be kept stable at 140°F (60°C) or above, whilst cold food must be kept stable at 40°F (4°C) or below.

- Reliable equipment and consistent temperature monitoring are non-negotiable.

- Rapid Cooling Procedures:

- Prompt cooling is fundamental to limit the time food spends within the danger zone.

- A two-stage cooling method is critical:

- Reducing the temperature from 135°F (57°C) to 70°F (21°C) within two hours is paramount.

- Further, the temperature should be decreased from 70°F (21°C) to 40°F (4°C) or lower within an additional four hours.

- Large-scale food production requires specialized cooling equipment, such as blast chillers, and provision must be made for this.

- Safe Reheating Practices:

- Reheating must bring food to a safe core temperature to kill any bacteria that may have proliferated during storage.

- 165°F (74°C) is recommended as a standard target for reheating.

3. Temperature Control

Proper temperature control is essential throughout food production from receiving of ingredients to dispatch of finished food product to ensure food safety and minimize the risk of foodborne illnesses.

Key Practices

- Cooking and Pasteurization: Foods must be cooked or pasteurized to specific temperatures to eliminate harmful pathogens.

- Hot Holding: Cooked foods should be kept stable at temperatures of 140°F (60°C) or higher to prevent bacterial growth.

- Cooling and Cold Holding: Cooked foods must be cooled rapidly to 40°F (4°C) or below and stored at that temperature to inhibit microbial activity.

- Reheating: Reheating should be done quickly and reach an internal temperature of 165°F (74°C) or higher.

Essential Equipment

- Accurate food thermometers are necessary for monitoring food temperatures.

- Temperature maintenance equipment: Steam tables, refrigerators, freezers, and rapid chillers are crucial for maintaining safe temperatures.

- Calibration: Temperature devices must be regularly calibrated to ensure accuracy.

Record Keeping

- Temperature records: Food producers must maintain accurate temperature readings and cooling times records for traceability and compliance.

Staff Training

- Safe food handling: All personnel must receive comprehensive training on safe food handling procedures, including proper temperature control.

4. Mitigating Risk of Cross-Contamination

Cross-contamination is the process by which harmful bacteria or other contaminants are transferred from one food or surface to another. This often occurs from raw meats, poultry, seafood, and eggs, which are common carriers of pathogens and necessitate careful handling to prevent the spread of contamination.

Key Prevention Strategies for Cross-Contamination:

- Separation:

- Keep raw and cooked foods physically apart during storage, preparation, and serving.

- Use separate, dedicated equipment and utensils for raw and cooked foods. Color-coding can help.

- Store raw meats on the lower refrigerator shelves to prevent dripping onto other foods.

- Cleaning and Sanitizing:

- Prioritize washing of hands thoroughly with soap and warm water, especially after handling raw foods.

- Clean and sanitize all food contact surfaces, cutting boards, and utensils that touch food.

- Use appropriate sanitizing solutions according to the manufacturer’s instructions.

- Regularly clean and sanitize high-touch surfaces.

- Proper Hygiene:

- Enforce strict handwashing protocols for all food handlers.

- Ensure employees maintain good personal hygiene, including clean clothing and hair restraints.

- Keep sick employees from handling food.

- Safe Food Handling:

- Cook foods to their proper internal temperatures to kill bacteria.

- Avoid washing raw poultry to prevent spreading bacteria.

- Thaw frozen foods in a safe manner using the refrigerator, cold water, or microwave.

- Facility Design and Flow

- Design food processing facilities to minimize cross-contamination risks

- Implement a one-way flow of food, from raw to cooked, to prevent backtracking.

- Create separate areas for raw and cooked food preparation.

- Implement proper waste disposal systems.

- Personnel Hygiene

- Maintain good personal hygiene, including frequent handwashing.

- Use and frequently change clean aprons to prevent cross-contamination from clothing.

- Training and Education

- Provide comprehensive training for all food handlers on safe handling and cross-contamination risks.

- Regularly reinforce food safety protocols.

- Stay up-to-date on local and federal food safety regulations.

- Allergen Control:

- Take extra precautions to prevent cross-contamination of allergens, which include using dedicated equipment and strict cleaning procedures.

By implementing these measures, food manufacturers can significantly reduce the risk of cross-contamination and protect consumers from foodborne illness.

5. Cleaning and Sanitization

It is highly necessary to regularly clean and sanitize all surfaces that touch food, utensils used in food processing, and food equipment and machinery.

Food handlers need to:

- Ensure all food-contact surfaces, tools, and equipment are consistently cleaned and sanitized to prevent contamination and safeguard against bacterial growth, and that maintenance is updated.

- Clean and sanitize all food-contact areas regularly, according to master cleaning schedules and daily cleaning checklists. Cleaning checklists really improve food safety and operational efficiency. They also hold staff and food handlers accountable for the upkeep of cleaning and sanitization in the food manufacturing plant.

6. Proper Storage of Food

Correct food storage is a critical component of preventing biological hazards and ensuring food safety as follows:

- Temperature Control:

- The “temperature danger zone” (between 40°F and 140°F or 4°C and 60°C) is where bacteria multiply rapidly. Keeping food outside of this zone is essential.

- Refrigerators must be maintained at 40°F (4°C) or below.

- Freezers must be kept at 0°F (-18°C) or below.

- Hot foods must be held at 140°F (60°C) or above.

- Preventing Cross-Contamination:

- Store raw meats, poultry, and seafood separately from ready-to-eat foods.

- Keep raw foods on the bottom shelves of refrigerators to prevent liquids from dripping onto other foods.

- Use airtight containers or sealed bags to store food.

- Proper Storage Techniques:

- Cool hot foods quickly before refrigerating them. Portion large quantities of food into smaller ones to accelerate cooling.

- Do not overload refrigerators or freezers, which can impede air circulation and affect temperature.

- Follow “first-in, first-out” (FIFO) principles to ensure that older food is used before newer food.

- Store dry goods in cool, dry places away from moisture and pests.

- Pay close attention to “use-by” and “best-before” dates.

- Container and Environment Hygiene:

- Use clean, food-grade containers for storage.

- Regularly clean refrigerators, freezers, and storage areas.

- Maintain a pest-free environment.

Specific Food Storage Considerations

- Raw Meat, Poultry, and Seafood:

- Keep these items in sealed containers on the lowest shelf of the refrigerator.

- Thaw frozen meats in the refrigerator, cold water, or the microwave – never at room temperature.

- Cooked Foods:

- Cool cooked foods quickly and refrigerate them within two hours.

- Store cooked foods in airtight containers.

- Fruits, Vegetables, and Dry Goods:

- Store fruits and vegetables according to their individual requirements. Some require refrigeration, while others are best stored at room temperature.

- Wash fruits and vegetables before use.

- To prevent pest infestation, store dry goods (such as flour, rice, and pasta) in airtight containers in a cool, dry place.

By keeping to to these storage practices, food manufacturers can greatly reduce the risk of food biological hazards and ensure the safety of their product supply.

So, what have we learnt from the various food safety practices we have just read about in preventing food biological hazards?

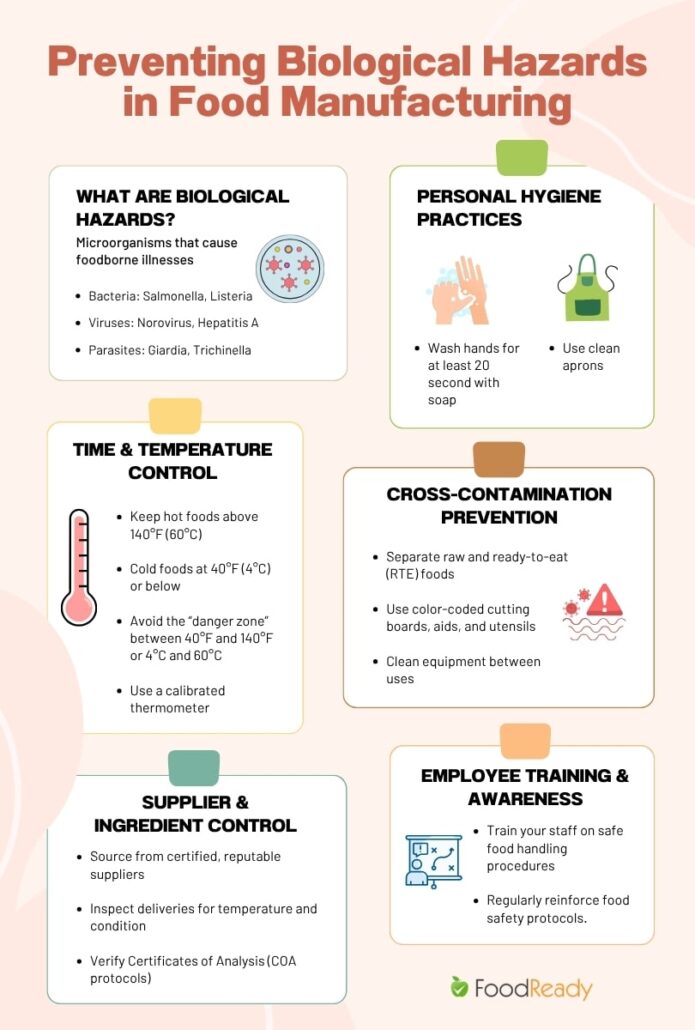

Let’s conclude with the infographic below:

How Can I Streamline the Monitoring, Analysis, and Control of Biological Hazards?

As a food manufacturer, you must manage the HACCP plan and ensure proper hazard monitoring and preventive actions.

With the help of a software solution that will take over all the hard work and help you eliminate errors, minimize risks, and improve food safety, you can guarantee automated and digitized hazard monitoring, food safety management, and workflow.

FoodReady food safety software enables food and beverage businesses to efficiently write and implement a HACCP plan, conduct hazard and CCP monitoring, oversee risk management procedures, manage emergency response actions, etc.

Need Help with Food Safety Monitoring?

Get expert guidance and automated tools to tackle biological hazards. Schedule your consultation with FoodReady today.

The software also integrates tools and services, such as barcode scanners, thermometers, and third-party laboratory testing, to efficiently monitor and identify biological food hazards.

FoodReady is a cost-effective solution that helps food and beverage companies prevent food contamination and avoid food recalls. Moreover, you can hire qualified food safety consultants to help with food safety plans, inspections, and other essential procedures.

Conclusion

Biological hazards, including bacteria, fungi, viruses, and parasites, exist all around us, and they are sometimes invisible and hard to kill. If biological hazards contaminate food, they can cause foodborne illnesses with symptoms like nausea, vomiting, fever, fatigue, etc. In a worst-case scenario, they can lead to death.

That’s why food manufacturers must be cautious to prevent them from getting into the food. If you wonder how to do that, you must implement food safety practices and ensure proper monitoring, preventive, and response measures.

If you still feel perplexed, we recommend using food safety software to facilitate and streamline your efforts. You will minimize biological contamination and ensure your clients consume safe, hazard-free products.

FAQs

To identify a food hazard, food manufacturers must constantly monitor and test their products, consult food safety consultants, stay updated about the latest food safety news, and monitor consumer feedback and complaints about the product.

Viruses and bacteria are the most common to provoke diseases among people.

Pregnant women, children, older adults, and people with weakened immune systems have higher risks of developing foodborne illnesses.