Cooling and reheating potentially hazardous foods (PHFs) are critical processes in food manufacturing that directly impact food safety and quality. PHFs require specific time-temperature control to prevent the growth of harmful microorganisms that can cause foodborne illnesses.

PHFs include meats, dairy products, cooked vegetables, and other high-protein, moisture-rich foods that, when not handled correctly, can become breeding grounds for bacteria such as Salmonella, E. coli, and Listeria.

Improper cooling and reheating practices can lead to serious health risks, regulatory violations, and costly recalls, making it essential for food and beverage manufacturers to implement effective procedures.

This guide explores the best practices for cooling and reheating potentially hazardous foods, outlines the risks involved, and provides actionable steps to ensure compliance and safety.

Understanding Potentially Hazardous Foods (PHFs)

Potentially Hazardous Foods (PHFs), also known as Time/Temperature Control for Safety (TCS) foods, require strict temperature control because they are susceptible to rapid bacterial growth. These foods typically have high moisture content, low acidity, and high protein levels, creating an ideal environment for microorganisms if not properly handled.

You can learn more about TCS foods in our detailed guide.

Common examples of PHFs include:

- Cooked meats, poultry, and seafood

- Dairy products such as milk, cheese, and yogurt

- Cooked rice, pasta, and beans

- Cooked vegetables and soups

- Eggs and egg-based dishes

Why Cooling and Reheating of PHFs Matter

Proper cooling and reheating of PHFs are essential to prevent foodborne illnesses caused by bacterial growth. Bacteria multiply rapidly between 40°F (4°C) and 140°F (60°C), a range known as the “Danger Zone.”

Keeping food out of this temperature range during cooling and reheating minimizes the risk of contamination.

1. Preventing Bacterial Growth

Proper cooling and reheating primarily aim to prevent bacteria from growing to dangerous levels. Cooling food too slowly or reheating it inadequately allows pathogens to thrive, increasing the risk of illness.

2. Maintaining Food Quality

Improper cooling and reheating can also affect the taste, texture, and overall food quality. Rapid cooling helps maintain the food’s intended characteristics, while proper reheating restores it to a safe condition without degrading its quality.

3. Compliance With Food Safety Regulations

Regulatory agencies like the U.S. Food and Drug Administration (FDA) and the U.S. Department of Agriculture (USDA) have established guidelines for cooling and reheating PHFs to ensure food safety. Manufacturers must adhere to these regulations to avoid penalties, recalls, and damage to their brand’s reputation.

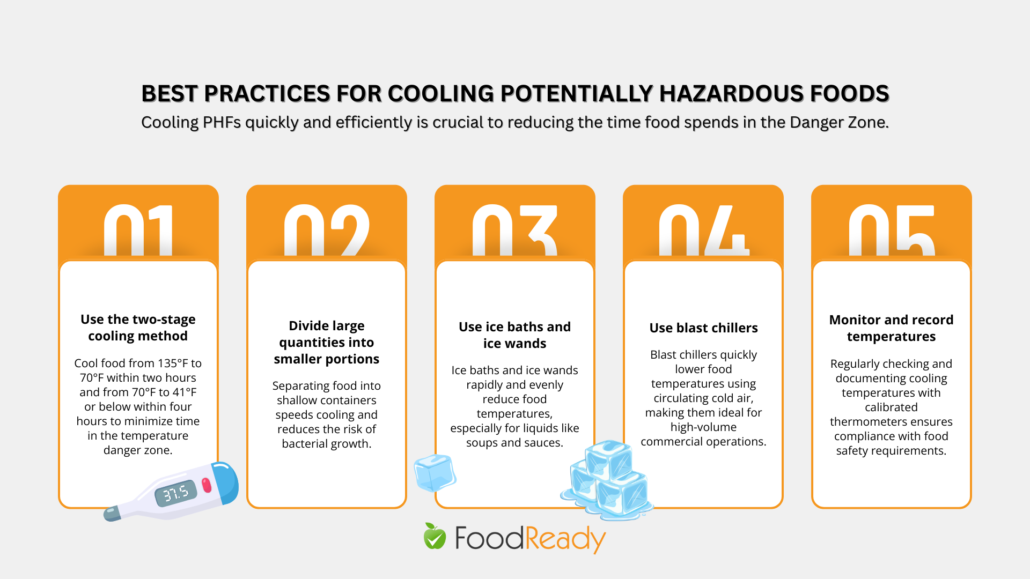

Best Practices for Cooling Potentially Hazardous Foods

Cooling PHFs quickly and efficiently is crucial to reducing the time food spends in the Danger Zone. Here are the best practices for cooling potentially hazardous foods:

1. Use the Two-Stage Cooling Method

The FDA recommends the two-stage cooling method to safely cool foods:

- Stage 1: Cool food from 135°F (57°C) to 70°F (21°C) within two hours.

- Stage 2: Cool food from 70°F (21°C) to 41°F (5°C) or below within four hours.

This process ensures food moves through the temperature danger zone as fast as possible.

2. Divide Large Quantities Into Smaller Portions

Large quantities of food take longer to cool, increasing the risk of bacterial growth. Divide large batches of food into smaller, shallow containers to increase the surface area and promote faster cooling. This method helps cool the food evenly and quickly.

3. Use Ice Baths and Ice Wands

Ice baths and ice wands are effective tools for rapidly cooling hot food. Submerging food containers in an ice bath or stirring with an ice wand helps lower the temperature quickly and evenly, especially for soups, sauces, and stews.

4. Use Blast Chillers

Blast chillers are designed to rapidly cool food by circulating cold air around the product, significantly reducing the cooling time. These are especially useful in commercial food manufacturing settings where large volumes of food need to be cooled quickly and safely.

5. Monitor and Record Temperatures

Regular temperature monitoring is essential to ensure that cooling processes meet food safety standards. Use calibrated thermometers to check food temperatures regularly and maintain records to demonstrate compliance with cooling guidelines.

Best Practices for Reheating Leftover Food, Potentially Hazardous Foods

Reheating PHFs to the correct temperature is just as important as cooling. Improper reheating can leave food at temperatures where bacteria can survive and multiply.

1. Reheat to Safe Temperatures

The FDA requires that PHFs be reheated to an internal temperature of at least 165°F (74°C) for 15 seconds before serving. This temperature is sufficient to kill most pathogens and make the food safe to consume.

2. Avoid Slow Reheating Methods

Slow reheating methods, such as steam tables, warmers, or holding ovens, can keep food in the Danger Zone for too long, allowing bacteria to multiply. Always use rapid reheating methods, such as stovetops, ovens, or microwaves, to quickly bring food up to the recommended temperature.

3. Stir Frequently for Even Heating

Stirring food during reheating helps distribute heat evenly, ensuring that all parts of the food reach the required temperature. This is particularly important for thick foods like stews and sauces, where cold spots can harbor bacteria.

4. Use Calibrated Thermometers

Use a calibrated food thermometer to check the internal temperature of reheated foods. Insert the thermometer into the thickest part of the food to ensure accurate readings, and avoid serving reheated food until it has reached the safe temperature threshold.

5. Avoid Reheating More Than Once

Repeatedly reheating the leftovers increases the risk of bacterial growth and can degrade food quality. Reheat food only once and discard any leftovers that have not been consumed.

Risks of Improper Cooling and Reheating

Failing to follow proper cooling and reheating procedures can lead to significant risks, including:

- Foodborne Illness: Improperly cooled or reheated foods are prime targets for bacteria such as Salmonella, E. coli, and Listeria, which can cause severe illness or even death.

- Regulatory Violations: Non-compliance with food safety regulations can result in fines, shutdowns, and legal action against food manufacturers.

- Product Recalls: Contaminated products that reach consumers can lead to costly recalls, loss of sales, and damage to the brand’s reputation.

- Loss of Consumer Trust: Food safety failures can erode consumer confidence in a brand, making it difficult to regain trust and market share.

Further reading: Essential Techniques for Bacterial Management in Food

Conclusion

Proper cooling and reheating of potentially hazardous foods are fundamental practices that safeguard food safety, maintain product quality, and ensure compliance with regulatory standards. By implementing effective cooling and reheating methods, food and beverage manufacturers can protect their consumers, reduce waste, and avoid costly recalls.

Adopting best practices, such as the two-stage cooling method, blast chillers, and reheating to the correct temperatures, can significantly mitigate the risks associated with PHFs. To uphold the highest standards of food safety, manufacturers must remain vigilant, consistently monitor temperatures, and educate their staff on the importance of these processes.

Ready to simplify cooling, reheating, and temperature monitoring?

Use FoodReady’s food safety software to track PHF controls digitally and stay audit-ready with confidence.

FAQs

Potentially hazardous foods require time-temperature control to prevent the growth of harmful bacteria. They include cooked meats, dairy products, cooked vegetables, and other moisture-rich, high-protein foods.

Proper cooling is crucial to prevent bacteria from growing in food that has been cooked and is cooling down. Cooling too slowly can leave food in the Danger Zone, where bacteria multiply rapidly.

The two-stage cooling method involves cooling food from 135°F to 70°F within two hours and then from 70°F to 41°F within four hours, ensuring rapid and safe cooling.

PHFs should be reheated to an internal temperature of at least 165°F for 15 seconds before serving to ensure that any bacteria present are killed. Read our detailed guide to learn about the temperature range that kills bacteria in food.

Reheating food multiple times increases the risk of bacterial growth and can degrade the quality. It is best to reheat food only once and discard any leftovers.

Improper practices can lead to foodborne illnesses, regulatory violations, product recalls, and loss of consumer trust.

Use calibrated thermometers to monitor temperatures, record cooling and reheating times, and train staff on safe handling practices to ensure compliance.

Technologies such as blast chillers, ice baths, and ice wands are highly efficient for rapidly cooling PHFs in manufacturing environments.