Managing product quality is challenging in the rapidly changing and highly regulated food and beverage industry. Here comes the QMS to facilitate and boost quality management. But what is a quality management system? Let’s answer this question.

In this blog, we will discuss the meaning of QMS, its benefits, how it works, how you can implement it, and other essential details.

What is a QMS?

QMS stands for Quality Management System, and it is an established framework to document various processes and procedures to ensure product quality and compliance with regulatory standards. In other words, it helps boost quality management in your company.

Quality Management System in the food and beverage business is as crucial as in life sciences, where it’s widely used. Incorporating a quality management system helps food and beverage companies achieve their business and production goals and enhance communication, productivity, and product quality.

Benefits of a Quality Management System in the Food Industry

Needless to say, QMS has more benefits for the food and drink industry than drawbacks. Let’s briefly review them and see how quality management systems can positively impact your business.

- Quality and compliance. First and foremost, implementing a quality management system has one significant benefit: it helps achieve food product quality, safety, and regulatory compliance faster and easier.

- Streamlined manufacturing process. Obviously, with a quality management system, you will boost the manufacturing process as it will become more structured, controlled, and efficient. Overall, you will guarantee more operational efficiency.

- Continuous improvement is another advantage, as it will be easier to encourage it through regular audits, reviews, and feedback.

- Cost reduction. A Quality Management System allows you to save money. You will minimize the risks of recalls and related costs and reduce waste, rework, and anything else that impacts spending.

- Brand reputation and leadership. It will make you a stronger competitor on the market, and you will win the trust of your customers, so they will be even more eager to continue buying your products.

Types of Quality Management Systems for the Food and Beverage Industry

Let’s see which quality management system standards apply to the food and beverage industry.

- ISO 9001. This is the most widespread and universal standard presented by the International Standards Organization. The standard establishes the requirements for quality management systems in different industries. It describes building quality management systems and designing and testing products.

- ISO 22000. The standard covers food safety and traceability throughout the supply chain worldwide. It has several sections that cover different areas of food safety.

- Six Sigma. Six Sigma methodology is used in the food and beverage industry to increase quality and effectiveness and minimize defects. It helps food and beverage companies comply with regulations, mitigate food contamination sources, improve customer satisfaction, etc.

- CMMI. Capability Maturity Model Integration is a framework with five maturity levels describing a company’s quality capabilities.

These standards are widely used in the food and beverage industry, and with one of them, you can guarantee quality and constantly improve your business and product.

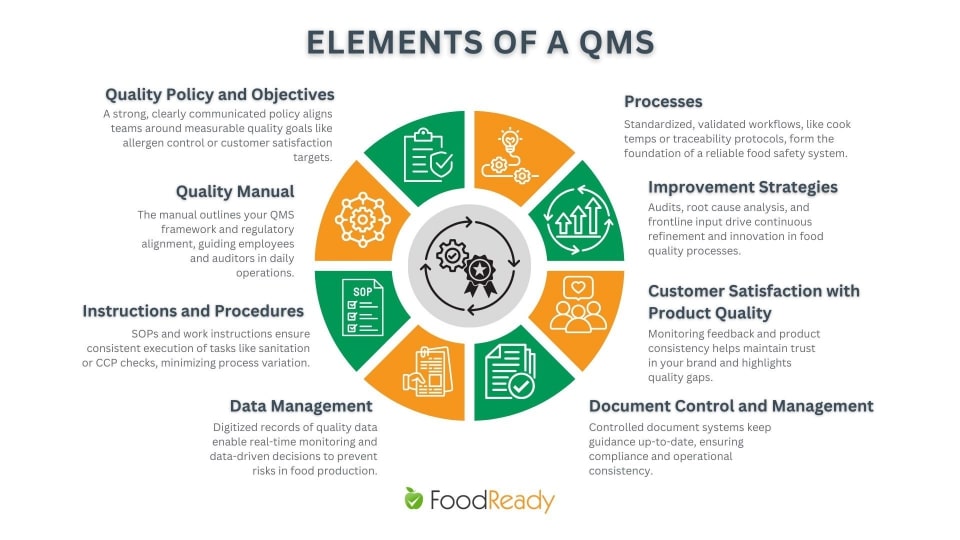

Key elements of a Quality Management System

You won’t find two identical quality management systems, as each has to be configured according to a company’s goals and needs. However, there are established components that are core to any QMS. Once you have them, you can add other elements.

Here are the critical facets of a quality management system:

1. Quality Policy and Objectives

This is the cornerstone of your QMS. It outlines your company’s commitment to quality, food safety, and regulatory compliance. A firm quality policy reflects leadership’s priorities and should be communicated clearly across departments. For example, a dairy processor might include objectives such as “zero allergen cross-contact incidents” or “maintain customer complaint rate below 1%.”

2. Quality Manual

The quality manual defines the structure of your QMS, its scope, and how it applies to your operations. It includes references to applicable regulations (like FDA, FSMA, or GFSI standards) and serves as a blueprint for employees and auditors. In a beverage bottling plant, the manual may detail how ISO 9001 and HACCP frameworks intersect in their facility.

3. Described Instructions and Procedures

Work instructions and SOPs are the actionable backbone of your QMS. These documents standardize key tasks, such as sanitation, allergen changeovers, or CCP monitoring, ensuring consistency and accountability across shifts. Clear procedures reduce variation and support regulatory inspections.

4. Data Management

Organizing quality data, such as lot traceability, audit findings, and CAPA reports, is vital for decision-making. This often involves digitized records to track temperature logs, batch yields, or microbial testing trends over time in the food sector. A structured data system enables a proactive response to potential risks.

5. Document Control and Management

Every form, record, and policy must be controlled, versioned, and accessible. This ensures your team is using the most current guidance. For example, if a cleaning SOP is revised due to a change in sanitizer concentration, the old version must be removed and the new one distributed promptly.

6. Customer Satisfaction with Product Quality

Measuring satisfaction is essential, whether through complaint tracking, product reviews, or sensory testing panels. This might involve monitoring consistency in texture, flavor, and labeling across production batches in a meat processing facility.

7. Improvement Strategies

Continuous improvement is the hallmark of a mature QMS. This involves refining processes through audits, root cause analysis, and employee feedback. For instance, implementing a Kaizen board in a commercial bakery may surface improvement ideas directly from line operators.

8. Processes

Your QMS must describe and document all standardized processes, from receiving and storage to final inspection. This includes validated cook steps, packaging integrity checks, and traceability from ingredient intake to distribution.

Once you have implemented these, you can tailor the QMS based on your business, objectives, and preferred ways of quality improvement.

QMS Principles

Apart from QMS elements, ISO 9001 includes principles applicable to any industry and company of any size. Here they are:

- Customer Focus – consider customers’ needs, opinions, and feedback and react to it.

- Leadership – correct guidance is pivotal in successful quality management.

- People Engagement – involve employees or suppliers and familiarize them with the quality standards you follow.

- Process Approach – streamline the processes to keep the workflow steady and smooth to ensure consistent quality.

- Continuous Improvement – systematically enhance overall performance by identifying areas for improvement and incorporating the changes.

- Evidence-based Decision Making – analyze the information and always make data-driven decisions.

- Relationship Management – communicate and collaborate with people throughout the whole supply chain.

These values play a pivotal role in any QMS, and you must accept and follow them to ensure proper QMS realization.

When and How to Implement a QMS?

Implementing a Quality Management System (QMS) may initially seem complex, and it is a serious undertaking.

But with a step-by-step approach, the process becomes manageable, focused, and tailored to your business goals.

Below is a structured guide to help food and beverage businesses implement a QMS with clarity and confidence:

Step 1: Assess Your Business Needs

Begin by analyzing your current operations, regulatory requirements, product types, risk level, and overall business objectives. Consider the scale of your operations, your market (local vs. international), and your audit or certification goals (e.g., SQF, BRCGS, or FSMA compliance).

A well-aligned QMS starts with clearly understanding where your business is and where it wants to go.

Step 2: Define Your QMS Framework

Based on your assessment, outline your QMS structure. This includes selecting relevant standards (e.g., ISO 9001, ISO 22000), identifying core components such as your quality policy, and mapping out critical processes like supplier approval, production checks, and customer complaint handling.

Align your plan with QMS principles like customer focus, continuous improvement, and evidence-based decision-making.

Step 3: Develop the System

Now build out your system’s documentation. Write or update your quality manual, SOPs, and recordkeeping templates. Define roles and responsibilities for quality tasks.

For example, a food processor might draft an allergen control plan, sanitation schedules, and a traceability matrix.

Ensure procedures are practical and reflect how work is done on the floor, not just how it looks on paper.

Step 4: Train Your Team

No system works without people. Provide role-specific training so your staff understands the QMS, their responsibilities, and tools like forms, log sheets, and audit checklists. Foster a culture of accountability and continuous improvement from the outset.

Step 5: Deploy and Monitor

Launch your QMS and begin collecting data. Start small if needed. Pilot the system in one area or department before a full rollout. Monitor early results to ensure procedures are followed. Track quality metrics (e.g., defect rates, customer complaints, audit findings) and look for areas of friction.

Step 6: Review and Improve Continuously

Set up regular internal audits, review meetings, and KPI tracking to evaluate performance. Adjust procedures and documents as needed. Respond to non-conformances with corrective action plans, and use findings to drive long-term improvement.

Step 7: Leverage QMS Software

Digitizing your QMS with the right software can significantly streamline implementation and management. From document control and supplier management to audit scheduling and real-time reporting, food quality management software for the food industry like FoodReady reduce complexity and improve visibility across your operation.

By following these structured steps, food and beverage businesses can build a QMS that’s compliant, scalable, efficient, and a true driver of product quality and brand trust.

New to Food QMS? We’ve Got You Covered

Whether you’re building your first system or upgrading from manual processes, FoodReady provides guided onboarding and expert support every step of the way.

Overcoming Implementation Challenges: QMS in the Real World

Implementing a Quality Management System can feel daunting, where fast-moving operations, strict regulations, and resource limitations often collide. While the benefits of QMS are substantial, getting it off the ground presents a few common hurdles. Here’s how to overcome them with practical strategies:

1. Lack of Internal Buy-In

Resistance from employees or leadership can delay or derail implementation. To address this, involve cross-functional teams early. Communicate how QMS supports food safety, regulatory compliance, and brand trust. Highlight how it will make their work more consistent and not more complicated.

2. Overcomplicated or Generic Systems

Many companies try to use systems that aren’t tailored to their industry. A generic QMS often lacks the flexibility or features needed for food safety (e.g., allergen control, batch traceability). Choose a food-focused solution like FoodReady that speaks your operational language.

3. Resource and Time Constraints

Building a QMS from scratch requires time, personnel, and training. To ease the burden, start small, prioritize high-risk processes or areas flagged in past audits. Use templates and software tools to speed up documentation and reduce manual input.

4. Keeping the System Updated

QMS is not a set-it-and-forget-it project. As regulations, products, and processes evolve, so must your system. Assign ownership for maintaining procedures, and set routine review checkpoints (e.g., quarterly SOP audits or post-recall updates).

5. Lack of Technical Infrastructure

Paper-based or disconnected systems lead to lost records, version control issues, and audit stress. Implement a digital QMS platform that supports document control, task tracking, and real-time reporting, all in one place.

By proactively anticipating and addressing these challenges, food businesses can set the foundation for a strong, flexible, and compliant QMS that adds value.

Discover FoodReady QMS Software

Using digital software to successfully work with quality management systems is always better.

FoodReady Quality Management System software is a digital solution for effective quality management. It will help you streamline and enhance the implementation and management of QMS.

FoodReady will provide a centralized platform for robust quality and food safety management, document control, supplier management, etc. It’s way better than confusing paperwork, multiple databases, and tools.

Imagine having a single platform that will guide you through the operations, and you will feel confident because your processes are organized and accessible in one app.

Digitize your quality management system and get professional help with FoodReady QMS software. Book a demo now to discover more!

Food QMS Summary

The quality management system is a framework to ensure product quality, safety, and customer satisfaction. Quality management system is a complex notion that requires a comprehensive approach.

If you are a food manufacturer, distributor, processor, or anyone who deals with food, you will need a QMS for your business.

Dealing with quality management systems demands effort, but it’s definitely worth it as you gain a lot of privileges with it, from enhanced food quality to streamlined business development.

To build and implement a QMS, consider its elements and principles, your business objectives and vision. It’s a challenge, but you can make it easier with the quality management software.

FoodReady can be tailored according to your quality management goals. Check out our features and book a demo to learn even more!

FAQs

Risk management helps identify, assess, and mitigate potential food safety and quality risks. A risk-based approach enables food and beverage companies to predict and prevent any issue from influencing product quality.

Trained employees significantly contribute to the effectiveness of a QMS. They must be well aware of quality standards, food safety protocols, and regulatory requirements.

You can measure effectiveness by tracking key performance indicators (KPIs) like customer satisfaction, regulation compliance, and the successful CAPA resolution. In addition, it’s also effective to run surveys and conduct audits and reviews to monitor the results.

There can be obstacles like the complexity of supply chain management, rapidly changing industry regulations, or lack of continuous improvement. To run the QMS effectively, the company has to overcome the challenges that arise.

HACCP is a food safety system focused on identifying and controlling specific hazards in a process (critical control points, limits, monitoring, and corrective actions). A QMS is broader: it manages overall quality and consistency across the business, including procedures, training, document control, audits, nonconformances, and continual improvement. HACCP can be one key part of a food company’s QMS.