If you’ve ever opened your storage room to find expired ingredients or had to toss out products that never got used in time, you know how costly poor stock rotation can be. Beyond the waste, there’s also the risk of serving unsafe food or failing an inspection.

FIFO, or “First In, First Out,” is a simple, reliable way to avoid these problems. By moving older stock first, you cut down on waste, maintain consistent quality, and comply with food safety regulations.

In this blog, I’ll explain FIFO in more detail. Let’s explore how it works, why it matters, and how to apply it effectively in your operation.

What does FIFO mean?

FIFO stands for “First In, First Out,” is an inventory management principle that ensures the first items added to inventory are the first ones to be used or sold. This method is widely used in industries dealing with perishable goods, such as food and pharmaceuticals, to ensure products are used before expiration.

In simpler terms, FIFO means that the oldest stock (the first items to enter the inventory) should be the first to be used or dispatched. This practice helps keep the inventory fresh and minimizes the risk of spoilage or obsolescence.

Why is FIFO necessary?

FIFO is critical because it helps reduce waste, maintain product quality, ensure customer satisfaction, and comply with safety standards. Using the oldest stock first, businesses can avoid spoilage and ensure customers receive fresh products.

Implementing FIFO in inventory management is crucial for several reasons. It reduces waste by ensuring older stock is used before it expires. It also helps maintain product quality by keeping items in their best condition. FIFO enables you to support compliance with food safety regulations and standards. By following the FIFO method, you contribute to customer satisfaction by guaranteeing that products are fresh and of high quality.

In which industries are FIFO particularly crucial?

FIFO is particularly crucial in industries dealing with perishable goods, such as the food and beverage industry, pharmaceuticals, cosmetics, and other sectors where product shelf life is a concern.

While FIFO can benefit various industries, it is especially vital in products with a limited shelf life. For instance:

- Food and Beverage: To ensure food safety and prevent spoilage.

- Pharmaceuticals: To maintain the efficacy and safety of medications.

- Cosmetics: To ensure products are used within their practical shelf life.

How can businesses implement FIFO in their operations?

Businesses can implement FIFO by organizing their inventory so that the oldest items are always at the front or top, using proper labeling and tracking systems, and training staff to follow FIFO protocols.

Implementing FIFO effectively requires a combination of organizational strategies and tools:

- Storage Organization: Arrange inventory so that older items are more accessible. For example, place newer items in a refrigerator at the back and older ones at the front.

- Labeling and Tracking: Use labels with dates and implement inventory tracking systems to monitor the age of products.

- Staff Training: Educate employees about the importance of FIFO and how to practice it during restocking and order fulfillment.

What tools and technologies can assist in practicing FIFO?

Several tools and technologies, including inventory management software, barcode systems, and RFID tags, can assist in practicing FIFO. These tools help track the age of inventory and ensure that the oldest items are used first.

Modern technology can significantly streamline the implementation of FIFO:

- Inventory Management Software: Automates inventory tracking and can alert staff when items are nearing their expiration date.

- Barcode Systems: Simplifies identifying and managing inventory by providing detailed information about each item.

- RFID Tags: Offer real-time tracking and inventory monitoring, prioritizing the oldest stock.

Can FIFO be applied manually without technology?

You can apply FIFO manually by organizing products physically and using manual tracking methods like logbooks or date labels. However, manual systems can be prone to errors and are less efficient than automated solutions.

While technology can enhance the implementation of FIFO, it is possible to practice it manually:

- Physical Organization: Arrange products so older items are always at the front or top.

- Manual Tracking: Use logbooks, spreadsheets, or simple date labels to track the age of products.

- Regular Audits: Conduct regular inventory audits to ensure compliance with FIFO practices.

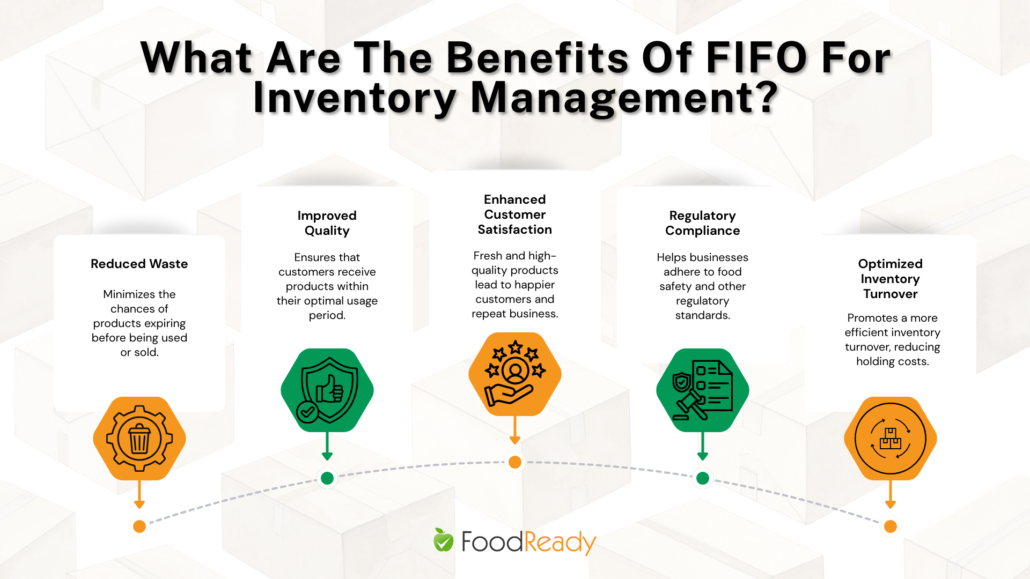

What are the benefits of FIFO for inventory management?

The benefits of FIFO for inventory management include reduced waste, improved product quality, enhanced customer satisfaction, better compliance with regulations, and optimized inventory turnover.

Practicing FIFO brings multiple advantages to businesses:

- Reduced Waste: Minimizes the chances of products expiring before being used or sold.

- Improved Quality: Ensures that customers receive products within their optimal usage period.

- Enhanced Customer Satisfaction: Fresh and high-quality products lead to happier customers and repeat business.

- Regulatory Compliance: Helps businesses adhere to food safety and other regulatory standards.

- Optimized Inventory Turnover: Promotes a more efficient inventory turnover, reducing holding costs.

How does FIFO impact food safety?

FIFO positively impacts food safety by ensuring that perishable items are used before they spoil, thus reducing the risk of foodborne illnesses and maintaining the overall quality of food products. Preventing spoiled or expired products from reaching customers is one of its most essential safeguards.

It helps prevent cross-contamination by reducing how long products stay in storage. At the same time, FIFO keeps businesses aligned with food safety regulations and standards, ensuring products remain safe for consumption.

Can FIFO help businesses save on costs?

FIFO can help save costs by reducing waste, minimizing spoilage, and optimizing inventory turnover. Efficient inventory management through FIFO can lead to lower storage costs and fewer losses due to expired products.

FIFO contributes to cost savings in various ways:

- Reduced Waste: Fewer expired and spoiled products mean lower costs associated with waste disposal.

- Optimized Storage: Efficient inventory turnover reduces the need for excessive storage space and associated costs.

- Fewer Losses: Minimizes financial losses from unsellable expired products.

Are there any challenges associated with implementing FIFO?

Challenges associated with implementing FIFO include the need for continuous monitoring, potential human error in manual systems, and the initial setup costs for automated systems. Ensuring compliance and maintaining organization can also be challenging.

While FIFO offers many benefits, it is not without challenges:

- Continuous Monitoring: Requires regular monitoring to ensure that the oldest items are used first.

- Human Error: Manual systems can be prone to mistakes, leading to potential lapses in FIFO compliance.

- Initial Costs: Setting up automated systems like inventory management software or RFID tags can involve significant initial investment.

- Maintenance: Ongoing efforts are needed to maintain the organization and ensure compliance with FIFO practices.

How is FIFO used in retail?

In retail, FIFO manages inventory by ensuring that older stock is displayed and sold first. This approach helps maintain product freshness and reduce waste from expired goods.

Retailers rely on FIFO to keep stock moving and minimize waste. Older products are placed at the front of shelves so they’re sold first, while newer items go to the back. The FIFO method helps sell seasonal goods within their intended period and track inventory more accurately to reduce losses caused by expired products.

How does FIFO apply to the food service industry?

In the food service industry, FIFO is applied to ensure that ingredients and prepared foods are used in the order they were received, maintaining freshness and food safety. This practice is essential in restaurants, cafeterias, and catering services.

Kitchens prevent spoilage and keep raw materials fresh by using older ingredients first. The same principle applies to prepared foods. Serving dishes in the order they were made ensures customers receive meals at their best while minimizing waste. Importantly, following FIFO, you manage operations according to health regulations and food safety standards.

What role does FIFO play in warehousing and logistics?

FIFO is a key principle in warehousing and logistics, ensuring older inventory is shipped first. This keeps products moving in the right order and reduces the risk of stock becoming obsolete.

It also helps maintain product quality by keeping items within their shelf life during storage and transport. At the same time, FIFO improves inventory turnover and lowers holding costs, making overall stock management more efficient.

Conclusion

FIFO, or “First In, First Out,” is a fundamental principle in inventory management that ensures the oldest stock is used or sold first. This method is vital for reducing waste, protecting quality, and staying compliant with safety regulations in industries like food, pharmaceuticals, and cosmetics.

Implementing FIFO can be done manually or with the help of various tools and technologies, each with its own set of benefits and challenges. By understanding and applying the FIFO principle, businesses can achieve more efficiency.

FAQs

For bulk items like flour, sugar, or spices, the FIFO method still applies, but you just need your own system. When a new product arrives, label the container or storage bin with the date you received it. Scoop from the older stock first before opening or using the newer one. This way, you keep freshness in check and avoid forgotten bags at the back of the shelf.

Inventory management software helps:

Track products by lot numbers and dates.

Receive automatic reminders when stock is approaching expiration.

Generate picking lists that highlight which items should be pulled first.

For busy manufacturers or food service operators, software ensures FIFO compliance even when operations scale up and you deal with multiple tasks.

Some common mistakes include:

– Improper labeling (missing or unclear dates).

– Overcrowded storage makes it hard to reach older stock.

– Untrained staff who unknowingly grab the easiest item instead of the oldest one.

To avoid these issues, keep the shelves tidy, standardize labeling, and provide quick, hands-on training. Also, regularly walk through the shelves to check compliance and spot problems early.

FIFO requires accurate date labeling, documented receiving records, and organized storage that supports stock rotation. It also depends on staff training and routine checks. Maintaining logs or digital audit trails will help you demonstrate proper FIFO practices during inspections.