If you work in food manufacturing, processing, or food service, you must be familiar with handling easily perishable foods. It’s important to understand what influences the safety and quality of certain foods, especially those that require the most attention.

In this blog, we will discuss the meaning of TCS foods, examples, the importance of maintaining TCS food safety, and many other essential questions.

What Are TCS Foods?

Some foods grow bacteria and pathogens quickly. These require Time and Temperature Controls for Safety (TCS) to avoid spoilage and contamination. In food safety, they’re considered high-risk. You may also hear them called Potentially Hazardous Foods, or PHFs. Without strict controls, they can become dangerous to human health. Even minor lapses in storage or handling can allow bacteria to multiply rapidly, making food unsafe.

What Does TCS and PHF Stand For?

In food safety, acronyms like TCS and PHF aren’t just jargon but crucial for preventing foodborne illness. TCS stands for Time and Temperature Control for Safety. This term applies to foods that require careful handling to keep them safe. These foods can quickly become breeding grounds for dangerous bacteria if not held at the right temperature or left out for too long.

PHF, or Potentially Hazardous Food, is the legacy term used in earlier regulatory language. While the industry now leans toward using TCS, both terms are often used interchangeably, especially in audits or inspections. The key difference is emphasis: PHF highlights the risk, while TCS highlights the required controls.

Think of it this way: PHF is the warning sign, and TCS is the protocol you follow to keep food safe. Understanding both is essential if you’re working toward compliance with standards like the FDA Food Code, GFSI, or state-level food safety rules.

| Aspect | TCS (Time/Temperature Control for Safety) | PHF (Potentially Hazardous Food) |

|---|---|---|

| Focus | Emphasizes required safety measures (time and temperature control) | Emphasizes the risk level of the food |

| Use in Regulation | Standard in modern food codes (FDA Food Code, GFSI audits, etc.) | Found in older regulations, still used interchangeably in some cases |

| Purpose | Guide for handling, storing, and monitoring high-risk foods | Classification of foods most likely to cause foodborne illness |

| Examples | Cut leafy greens, dairy, shellfish, and cooked rice | The same examples apply; PHF is the risk category |

| Why It Matters | Helps establish procedures for safe food handling | Highlights why a food needs control to remain safe |

Why Is It Crucial To Keep TCS and PHF Foods Safe?

You must monitor TCS or PHF foods for safety, regulatory compliance, and financial reasons.

Firstly, food safety is the most obvious reason. You must protect your customers from any risks of foodborne illnesses. TCS foods are particularly susceptible to pathogen growth if not properly managed, making strict controls essential to prevent microbial proliferation and ensure public health. It’s crucial to prevent diseases and ensure public health.

Secondly, you will adhere to state and federal regulations regarding food safety, such as FDA or GMP. Otherwise, you risk losing your business. If you want to pass the GFSI audit or any other certification, you will also be checked for how you treat TCS foods.

Lastly, an irresponsible attitude towards TCS food can lead to waste and recalls that affect a company’s budget. What’s more, not only does a manufacturer or caterer lose money but also the customer who pays to get a quality product. A thoughtful approach can save you time, money, and a client.

Who Uses the Terms PHF and TCS Foods?

These terms are used in the food manufacturing and food safety world. FoodReady food safety software and consulting can help your food and beverage business implement a system to keep your TCS foods safe.

What Makes up TCS or PHF Foods?

TCS and PHF foods have several qualities which make them susceptible to spoilage and bacterial growth.

- They contain moisture. Some foods like fruits and vegetables, seafood, etc, have higher moisture content, which leads to faster bacterial growth.

- They have higher protein and carbohydrate levels. Protein and carbohydrates support the spread of bacteria in food.

- They are neutral or slightly acidic in nature. Bacteria grow less in acidic environments, whereas low acidity boosts their growth.

Attention to these aspects is essential. Refrigeration and proper storage will extend the food’s shelf life and prevent contamination and foodborne illnesses.

Take Control of Your TCS Food Safety

Ready to stop guessing and start tracking? Monitor TCS food temperatures with confidence using FoodReady’s digital tools.

Why the Temperature Danger Zone Matters?

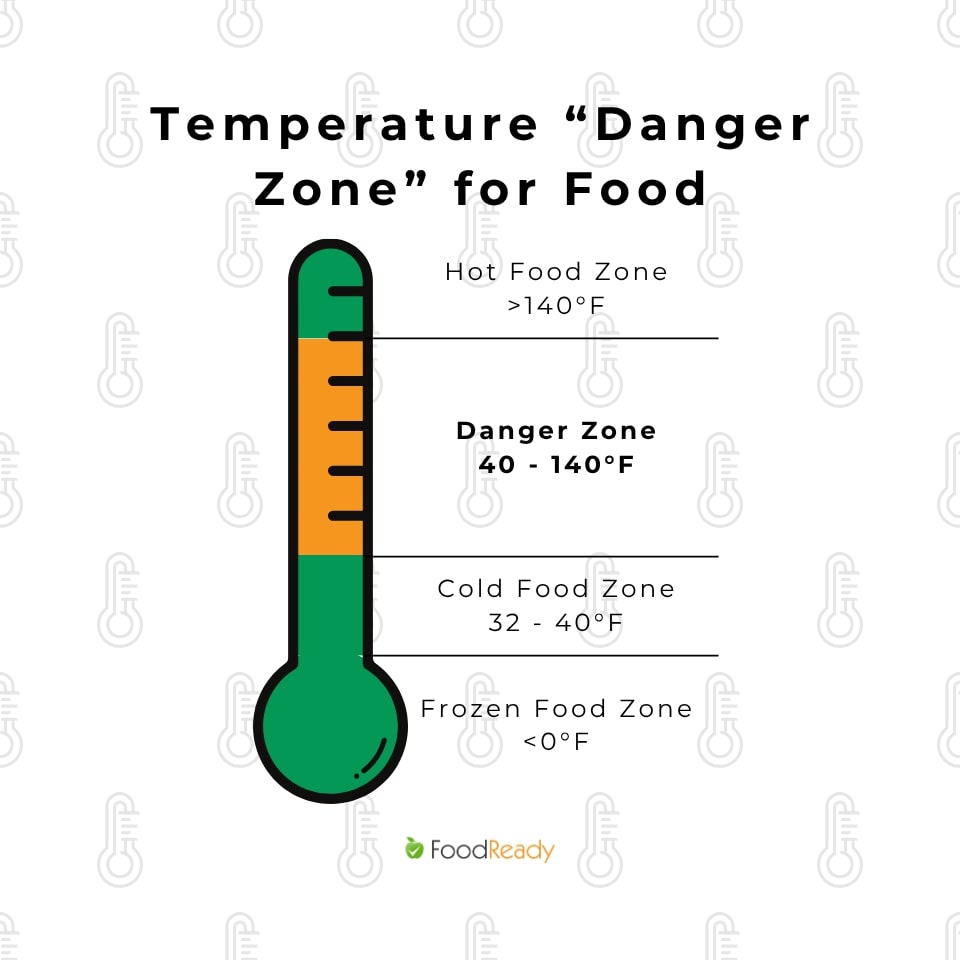

Whether labeled as TCS or PHF, these foods must be kept out of the “Danger Zone”: the temperature range between 40°F and 140°F. This is where bacteria like Salmonella, E. coli, and Listeria thrive and multiply rapidly. Even a few hours in this range can allow dangerous pathogens to grow to levels that cause foodborne illness.

To keep food safe:

- Cold foods should be stored at 40°F or below

- Hot foods must be maintained at 140°F or above

Crossing into the danger zone compromises food safety, making tight temperature control essential from preparation through storage and transport.

1. How Do We Keep TCS Foods and PHFs Safe To Eat?

These foods are kept safe by keeping the time spent in temperatures (41°-145° F) to a minimum. Hence, the phrase “time and temperature controls”. Minimize the time foods are kept in this temperature “danger zone”.

2. How Long Can Food Be Safely Left Out?

Cold foods are safe for up to six hours as long as the internal temperature stays below the threshold of 70°F. Any food left out longer than four hours or with a temperature above 70° should be tossed out. Any food whose temperature has not been checked should be tossed out after four hours.

Hot or “hot-held” foods can be served for four hours and thrown out after the four-hour mark.

Foods that are served immediately after reheating do not require hot holding, but they must reach a safe internal temperature of 165°F quickly, typically within two hours, to ensure safety.

What Are Some Examples of Common Types of TCS Foods and PHFs?

Let’s take a look at some of the most popular and common TCS food examples. This list highlights the most common TCS foods that require strict temperature control for safety:

- Leafy greens and sprouts: Includes cut greens like lettuce, chard, and spinach, as well as raw sprouts such as mung bean, alfalfa, and broccoli.

- Fruits: Cooked vegetables, sliced melons, and cut tomatoes (e.g., diced or sliced).

- Animal-based proteins: Covers a wide range of meat products, cooked, raw, and uncured, including fish, shellfish, and eggs, and frozen foods.

- Prepared dishes: Includes high-risk foods like potato salad, mashed potatoes, and frozen foods, which combine moisture and proteins.

- Dairy products: Milk, cheese, and other dairy items with moisture and neutral pH that support bacterial growth.

Prepared dishes: Includes high-risk foods like potato salad and mashed potatoes, which combine moisture and proteins. - Protein-rich plant foods: Legumes, tofu, and other plant-based products rich in protein and susceptible to spoilage.

Unlike TCS foods, other foods do not require the same strict temperature controls, but still need proper storage and handling to prevent contamination.

Why Can TCS Foods and PHFs Become Dangerous?

TCS foods use and/or contain the three elements that bacteria needs to multiply

- Food

- Moisture

- Warmth

Small amounts of bacteria are not a problem, but when they multiply to large amounts foodborne illness can occur to those who eat these foods.

How Do We Keep TCS Foods and PHFs Safe To Eat?

These foods are kept safe by keeping the amount of time spent in temperatures (41°-145° F) to a minimum. Hence the phrase “time and temperature controls”. Minimize the time foods are kept in this temperature “danger zone”.

How Long Can Food Be Safely Left Out?

Cold foods are safe for up to six hours as long as the internal temp stays below the threshold of 70°. Any food left out longer than four hours or whose temperature has risen above 70° should be tossed out. Any food whose temp has been unchecked should be tossed out at four hours. When handling hot foods, it’s important to cool food quickly and efficiently to prevent bacterial growth, use shallow containers and refrigerate promptly to keep foods safe.

Hot or “hot-held” foods can be served for four hours and thrown out after the four-hour mark. When reheating foods, always ensure they reach a safe internal temperature of 165°F before serving to eliminate bacteria and reduce the risk of foodborne illness.

How Do I Properly Store TCS and PHF Foods?

All TCS and PHF foods should be stored in a refrigerator, freezer, or heated countertop at the appropriate temperature. It’s important to keep track of the temperatures in each location to ensure that food is kept safe. Additionally, avoid cross-contamination by storing food separately and away from potential sources of contamination, such as raw meat, poultry, fish, and eggs.

Food packaging can also help store and transport TCS food according to safety norms, as it protects the food from cross-contamination. Also, different types of packaging can prolong the shelf life of a TCS food product. For example, vacuum packaging makes food last longer, protecting it from oxygen and microorganisms.

FDA Guidance When Cooling Foods

The FDA Model Food Code outlines a strict two-stage cooling process for TCS foods. First, cool hot food from 135°F to 70°F within two hours. This step is critical; bacteria multiply most rapidly in this range. Next, bring the food down to 40°F within four more hours. Altogether, cooling must not exceed six hours. If food doesn’t meet these times, it must be reheated, cooled properly, or discarded to avoid safety risks.

FDA Guidance When Warming Foods

Because the foods must be reheated in two hours or less it is recommended they be heated using an oven, microwave or stove because the proper temperature will not be reached if using warm “holding” equipment. Using the holding equipment would allow time for bacteria and pathogens to grow.

TCS Foods in the Food Service Industry

In the food service industry, managing TCS foods, those requiring Time and Temperature Control for Safety, is a top priority for preventing foodborne illnesses. These foods are especially vulnerable to the rapid growth of harmful bacteria if not handled with strict temperature controls. Because food service operations often prepare, store, and serve large quantities of food, understanding which foods are considered TCS foods and how to manage them is essential for customer safety and regulatory compliance.

Proper temperature control is at the heart of food safety in restaurants, cafeterias, catering, and other food service settings. Foods like cooked rice, leafy greens, dairy products, meat, and cut fruits must be kept out of the temperature danger zone to prevent the growth of dangerous bacteria. This means cold foods need to be held at or below 40°F, while hot foods must be kept at or above 140°F. Time and temperature control measures, such as regular temperature checks, using calibrated thermometers, and minimizing the time food spends in the danger zone, are critical steps in keeping TCS foods safe.

Food service professionals must also be vigilant about cross contamination and ensure that TCS foods are stored, prepared, and served using best practices. By following strict temperature controls and handling guidelines, food service establishments can significantly reduce the risk of foodborne illnesses and keep their customers safe.

Handle TCS Foods With a Digital Solution

FoodReady is food safety software that will assist you with managing and digitizing food safety operations.

The software has robust temperature and environmental monitoring features that will help you control the TCS foods in the required conditions and identify any potential hazards or issues.

Apart from temperature monitoring, you’ll receive a comprehensive set of tools like document management, batch and lot traceability, supplier management, CAPA, and HACCP builder. You can also use the help of our food safety consultants to comply with State, USDA, or FDA regulations.

Contact our sales team to get a demo!

FAQs

Signs that a food has spoiled include a visible change in color, texture, or odor, as well as any signs of mold or bacteria growth. If you are unsure whether a food has gone bad, it is best to throw it out and buy a new one.

Use separate utensils, cutting boards, and wash hands thoroughly before, during, and after handling food. Use a thermometer to check cooked foods.

If you think you have food poisoning, contact your healthcare provider and local health department.

If leftover food has been left out at an unsafe temperature or smells, looks, or tastes bad, throw it out immediately into a sealed container.

It is recommended that manufacturers and restaurants check the temperatures in their refrigerators and freezers with an accurate thermometer at least twice a day.

Non TCS foods are foods that do not require strict temperature controls for safety. These foods typically have low moisture, low pH, or high acid content, which makes them less prone to bacterial growth and safe to store at room temperature. Examples include dry goods like rice, pasta, and certain baked goods.