Preventing cross-contamination has been one of the most critical challenges in food manufacturing, and food businesses often dread contamination incidents and the effects they can have on people’s lives and business perspectives.

Understanding the nature of cross-contamination and methods to prevent cross-contamination in food handling can significantly alleviate the struggle with the issue and protect both consumers and your own food business.

In this article, I’ll explain what causes cross-contamination, how it happens, how to prevent food contamination, and how to simplify your daily food safety operations.

What Is Cross Contamination?

Cross-contamination means the transfer of harmful bacteria, viruses, microorganisms, or allergens from utensils, foods, or people to other objects and foods. It can cause foodborne illnesses.

Cross-contamination of food is more likely to happen when handling raw foods like meat, seafood, eggs, etc. Cooked meals and products can also be contaminated if not separated. For that reason, food handlers must be careful to avoid cross-contamination in self-service areas and production lines. Proper training and awareness can easily tackle this issue.

What Are the Types of Сross-Сontamination?

Cross-contamination can take different forms, which influences how the issue is handled. Below are some main pathways of cross-contamination.

1. Food-to-Food

The most apparent type of cross-contamination is food-to-food, which means that pathogens can move from one product to another that touched it. Food can contaminate other ingredients, for example, when it is not separated correctly (raw and processed products), stored, or washed.

Preventing food cross-contamination between raw meat and ready-to-eat items is critical.

2. People-to-Food

People also carry hazards, which is why they can contaminate food with bacteria, viruses, or even physical pathogens. Therefore, sick workers are prohibited from working with food, and how food workers can prevent contamination includes following strict sanitation protocols and proper personal hygiene.

3. Equipment-to-Food

If your sanitation procedures are insufficient, leftovers on the equipment, bacteria, or allergens can get into the food it touches—the same with utensils, boards, and surfaces. Imagine cutting salad with the unwashed knife you used to cut raw chicken. Cross-contamination is most likely to occur when food handlers do not clean and sanitize equipment and surfaces between uses.

Who Can Be Affected by Cross-Contamination?

People who consume a contaminated product can suffer from a foodborne illness, allergies, or other adverse effects. But pregnant women, the elderly, children, or people with weaker immune systems are at a much higher risk.

To avoid these risks, food manufacturers must understand how cross-contamination happens. It will help them foresee potential issues.

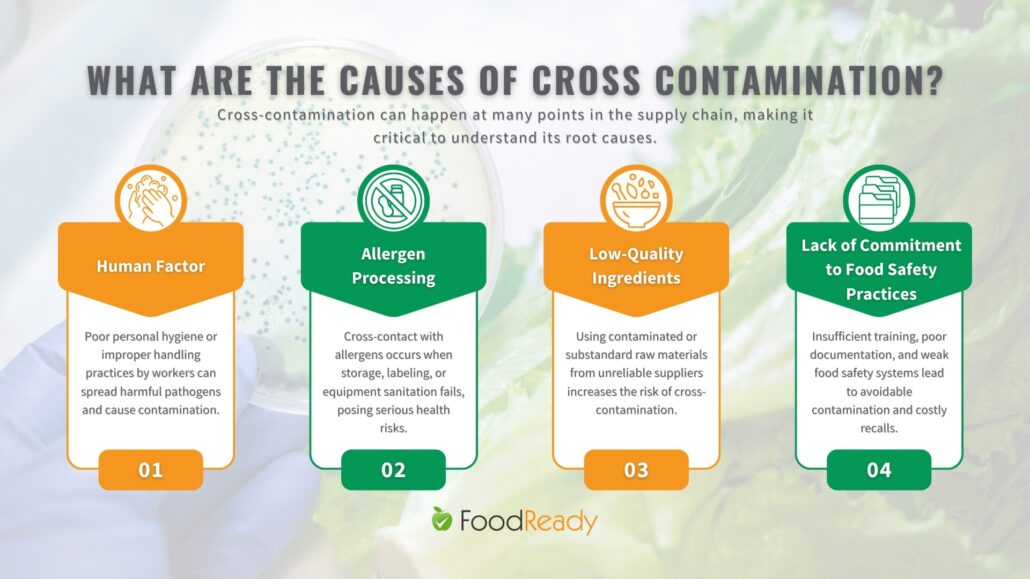

What Are the Causes of Cross Contamination?

Cross-contamination can occur in different scenarios and at various supply chain stages, but it’s essential to know why the chances of contamination exist.

1. Human Factor

Human factors can cause some human errors that lead to cross-contamination. Examples can include improper personal hygiene: cross-contamination has occurred when a worker didn’t wash their hands properly or forgot to change the dirty apron. This is how contamination can be caused by carrying bacteria from one area to another.

2. Allergen Processing

One of the most common types of cross-contamination is the introduction of allergens into food. Allergenic ingredients must be stored separately, and equipment must be cleaned properly to prevent cross-contamination from occurring when allergens are not declared.

Food labels must declare all allergenic ingredients in each product and whether the food has come into contact with equipment that has been in contact with allergenic ingredients.

3. Low-Quality Ingredients

Low-quality raw food is a common source of cross-contamination, so you must monitor your suppliers to prevent spoilage. It’s best to have pre-approved suppliers that maintain high food safety standards and have been certified by third-party auditors.

4. Lack of Commitment to Food Safety Practices

If your facility lacks a proper food safety management system, has disorganized recordkeeping procedures, and has workers who are not adequately trained about safe food handling, you risk selling a contaminated product that will eventually be recalled.

The problem often boils down to human-made mistakes and insufficient food safety management. Food manufacturers must be consistent and aware of the risks and ways to maintain a safe food handling environment.

A lack of understanding of how cross-contamination occurs is often to blame.

Beware of the Cross Contamination Consequences

Consuming contaminated products can cause foodborne illnesses, from food poisoning to serious health problems requiring hospitalization. Typical symptoms of food poisoning are nausea, vomiting, diarrhea, fever, and dehydration.

Eating contaminated food can also cause chronic diseases like kidney failure or neurological disorders. Cross-contamination with allergens can trigger life-threatening allergic reactions.

Let’s remember about the fear and anxiety caused by consuming contaminated food. People can suffer from psychological issues badly influencing their quality of life and eating habits.

From the manufacturer’s perspective, putting customers at risk can cost a lot in terms of reputation and finances. A contaminated product will be recalled, causing financial losses. Food businesses can also lose their certifications, get fined, fall under increased scrutiny, receive more attention from regulatory bodies, and be audited more frequently.

Companies will experience downtime, increased costs, and loss of employee morale. Contamination incidents will also adversely impact the company’s reputation.

Cross-contamination affects customers and manufacturers, so prevention is the only way to avoid mistakes.

But how can you do that?

What Is the Best Way To Avoid Cross Contamination?

To prevent cross-contamination, you should implement various strategies regarding operational aspects, sanitation, supply chain management, etc. Here are some insights into these strategies.

- Understand food safety hazards. You must understand what dangers can cause cross-contamination risks. These could be biological hazards, physical hazards, or chemical hazards.

- Implement a HACCP Plan into your production. A HACCP plan will help you monitor hazards more efficiently and spot potential contaminants in advance.

- Cleanliness and Sanitation. Incorporate SOPs on hygiene, cleaning, and sanitation to prevent cross-contamination caused by improper personal hygiene, insufficiently cleaned and sanitized equipment, etc.

- Pest control. Pests can quickly appear in food and turn into physical and biological hazards. You must implement a pest control system and dispose of products accordingly, as pests usually occur due to improper waste management.

- Temperature monitoring. The most effective way to kill pathogens is to control storage temperature and process food under the established temperatures. IoT devices like Bluetooth thermometers and other monitoring equipment can accomplish this task.

- Food handling. Train employees to follow food handling procedures strictly. The practices will include separating food, cooking conditions, storage, sanitation and more. Explain your team why chopping board colors matter in food safety.

- Supplier monitoring is an indispensable part of cross-contamination prevention. Verify supplier documents, track their performance, and double-check if they follow food safety practices. Suppliers sometimes provide a contaminated product to your facility; you must foresee and prevent that.

- Use digital tools to facilitate food safety and quality management at your facility. Software and IoT devices will automate the processes and help reduce human errors, downtime, and cross-contamination risks.

Preventing Cross-Contamination with a Risk-Based Approach

The journey from farm to fork involves multiple stages where cross-contamination risks can arise, including farming, manufacturing, distribution, retail, and food service. At each point, harmful microorganisms can be transferred through soil, water, equipment, handling practices, or temperature abuse, putting consumer health and brand integrity at risk. Managing these risks requires a risk-based approach that identifies stage-specific hazards and applies targeted controls. By embedding food safety into every step of the supply chain, businesses can reduce contamination incidents and maintain regulatory compliance.

Understanding the Risks at Each Stage

- Farming: Contamination can occur from the use of contaminated water, improper use of fertilizers and pesticides, and interaction with wildlife or livestock. Strategies here include regular testing of water sources, controlled use of agricultural chemicals, and implementing biosecurity measures to limit animal contact with crops.

- Manufacturing: The risks at this stage include contamination from processing equipment, packaging materials, human handling, and environment. Preventive measures include supplier approval, regular equipment sanitization, strict control of processing environments (e.g., air quality and humidity), and rigorous employee hygiene practices.

- Distribution: During transportation, food products can be exposed to contaminants through improper handling and fluctuations in temperature. Key preventive strategies include maintaining controlled transportation environments, regular vehicle cleaning, and ensuring strict adherence to safe handling practices.

- Retail: At this stage, cross-contamination can occur through handling by employees and customers, as well as through contact with other food products. Retailers can mitigate these risks through proper food storage and display, employee training in food safety, and maintaining clean and sanitized facilities.

- Restaurant Operations: In restaurants, cross-contamination can happen during food preparation and serving. Preventive measures include separate preparation areas for raw and cooked foods, use of designated utensils and cutting boards for different types of food, and rigorous staff training in food safety practices.

Implementing a Risk-Based Approach

Adopting a risk-based approach involves:

- Regular Risk Assessments: Identifying and evaluating potential hazards at each stage of the supply chain.

- Tailored Prevention Strategies: Developing and implementing control measures that are specific to the risks identified at each stage to prevent cross-contamination.

- Monitoring and Evaluation: Continuously monitoring the effectiveness of these measures and adjusting them as needed.

- Employee Training and Awareness: Ensuring that all staff members are trained in food safety practices and understand the importance of their role in preventing cross-contamination.

- Compliance with Regulations: Staying up-to-date with food safety regulations and ensuring all operations are in compliance.

Real Cases of Cross-Contamination

Unfortunately, foodborne illness outbreaks happen often, many of which are caused by cross contamination. Sometimes, we need to delve deeper into this topic and see real examples to understand the extent of the problem and how to prevent it.

Caito Foods’ pre-cut melon Salmonella outbreak occurred in 2019. Caito Foods voluntarily recalled fresh-cut watermelon, honeydew, cantaloupe, and mixed fruit melons because of potential contamination from Salmonella bacteria.

The products were distributed to Illinois, Indiana, Iowa, Kansas, Kentucky, Michigan, Minnesota, Missouri, Nebraska, New York, North Carolina, Ohio, Pennsylvania, Tennessee, West Virginia, and Wisconsin. Different sources report that the contamination affected around a hundred US people aged from less than a year old to a 98-year-old.

JBS Tolleson, Inc. recalled approximately 12 million pounds of raw beef products because of Salmonella contamination. In 2018, it affected nearly 250 people.

The FDA and CDC (Centers for Disease Control) investigated an outbreak of Salmonella in diced onions sold in the U.S. and Canada. According to the FDA, the outbreak resulted in 80 illnesses, 18 hospitalizations, and one death.

These highlight the need to prevent contamination in food processing and packaging.

Digital Solutions To Prevent Cross-Contamination

Nowadays, AI, IoT, and other technologies have significantly facilitated food safety management, and preventing food contamination has become a more achievable task. Here’s how a software solution like FoodReady can help you.

FoodReady software will digitize food safety at your facility to prevent cross-contamination and make it more manageable. It enables efficient HACCP management, CPP monitoring, document management, supplier monitoring, and more. You’ll efficiently manage sanitation procedures, SOPs, equipment maintenance, etc.

FoodReady will replace multiple tools and platforms and centralize workflow. We want to provide a complex solution, offering professional advice from our food safety consultants on your FSMS, HACCP plan, recall actions, audit preparation, and more.

Implementing an automated and centralized solution is a game changer for the food and beverage businesses.

Contact us to learn more about what we can help you with!

Prevent Cross-Contamination Before It Starts

Detect risks early and maintain full traceability across your facility.

Conclusion

Preventing cross-contamination across the food supply chain requires ongoing, coordinated effort from all stakeholders, as hazards can arise from food, people, equipment, and processes at every stage from farm to fork.

By understanding these risks and applying a robust, risk-based food safety strategy, food businesses can significantly reduce foodborne illness, protect consumer health, and safeguard their reputation. Implementing strict hygiene practices, maintaining clear documentation, and following proven food safety procedures are essential to avoiding costly and preventable failures.

When managing these requirements becomes complex, digital food safety solutions like FoodReady can help streamline compliance and minimize contamination risks.

FAQs

Businesses must establish monitoring procedures, track their suppliers’ performance, ensure proper document verification, etc.

A well-thought-out facility plan can significantly improve food safety and reduce cross-contamination risks. Examples of well-designed facilities include planned zoning for raw and processed foods, properly established pathways for workers, and accessible and adequate sanitizing areas.

Plan the facility layout and product storage. Use different equipment for raw and processed foods; for example – you can implement color-coding to differentiate the tool’s purpose.

There are several ways. For example, food can be put in unsanitized packaging, or non-hermetic packaging can allow pathogens to contaminate food from the environment.

Educating consumers on safe food handling practices, such as proper storage, cooking temperatures, and avoiding cross-contamination at home, is crucial. Awareness campaigns can empower consumers to act as an additional line of defense against foodborne illnesses.

Simple and cost-effective practices like crop rotation, natural pest control methods, regular handwashing, and basic sanitation can significantly reduce the risk of contamination. Community-based training and resource-sharing initiatives can also support these efforts.

The design of equipment and facilities with hygiene in mind, such as smooth, easy-to-clean surfaces, minimal crevices where bacteria can hide, and effective drainage systems, can drastically reduce contamination risks. Incorporating sanitary design principles from the outset is key.

Emerging trends include stricter regulations on traceability, enhanced transparency requirements, and the adoption of international food safety standards. Businesses should stay informed about changes, invest in training, and adopt a proactive approach to compliance and risk management.