The food industry bears a dual responsibility: to follow legal standards and to maintain its commitment to consumers by ensuring the quality and safety of food products. This effort includes central food inspection reports, which are essential in evaluating documents for manufacturing, processing, and service installations. These reports ensure compliance and highlight areas of non-transportation and possible risks, enabling organizations to take corrective action.

In this article, we examine the importance of food inspection reports, outline the process of making them, and investigate how to change the way of managing food security inspections.

Meaning of a Food Inspection Report

A food inspection report is a comprehensive document compiled after a manufacturing, food processing, or service facility inspection. The report summarizing inspection results assesses compliance with food safety regulations and identifies potential risks that could affect food safety.

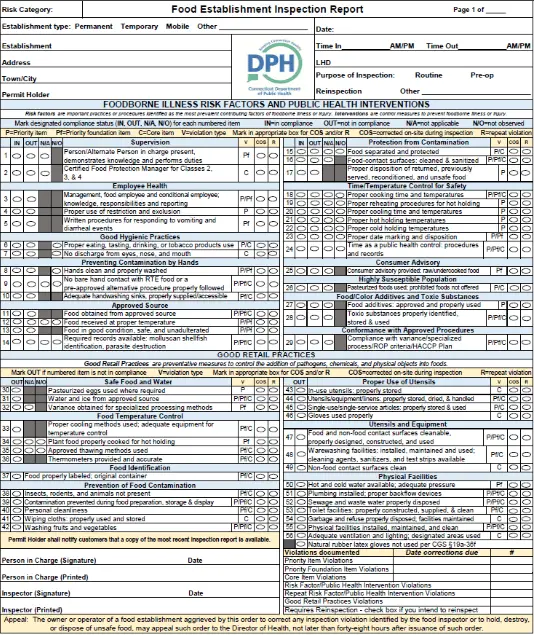

Here is a sample PDF food inspection report.

What Are the Key Components of a Food Inspection Report?

- Facility information: name, address, establishment type, and contact information.

- Inspection details: Date, time, name, and type of investigator (e.g., routine, follow-up, or complaint) of the inspection.

- Assessment Criteria: A detailed assessment based on specific regulations or standards, such as hygiene practices, cleaning the equipment, pest control, and temperature management

- Violations or Non-Compliance: Description of the observed violation, severity, and applicable conduct.

- Corrective Actions: Suggestions to address violations, including the deadline for compliance.

- Inspector’s Notes: Additional observations or comments related to the operation or management of the facility.

- Signature: Signature of the investigator and facility representative acknowledging the findings.

These reports serve as benchmarks for food safety practices to ensure public health protection and compliance with local, state, and federal regulations.

What is the Importance of Food Inspection Reports?

- Public Health Assurance: Routine surveillance identifies risks and prevents foodborne illnesses before they become serious.

- Compliance: Helps businesses meet stringent legal requirements enforced by agencies such as the FDA, USDA, or local health departments.

- Building consumer trust: Transparent adherence to food safety standards increases trust in your brand.

- Operational efficiency: The report highlights areas for improvement and allows businesses to optimize processes and reduce waste or errors.

- Legal Safety: A recorded compliance history can protect a business during an audit or legal challenge.

Types of Food Inspections: What Inspectors Look For and Report On?

The type of food inspection reports depends on the type of inspection. Let’s see the most common types of food inspections and the reports they follow:

- Regular inspections: Regularly scheduled inspections to ensure continued compliance with food safety regulations.

- Follow-up inspections: Conducted to verify that previously identified violations have been corrected.

- Complaint-based inspections: Initiated in response to consumer complaints regarding food safety issues.

- Pre-Operation Inspection: Conducted before the start of operation of a new facility to ensure compliance.

- Hazard Analysis Tracking: Focuses on identifying and managing specific risks within the facility.

Challenges in Managing Food Inspection Reports

- Complex regulations: The application of various food safety regulations can be a matter of concern. This is especially true for establishments operating in multiple locations.

- Human error: Manual compliance checks and corrective actions are prone to mistakes.

- Over-documentation: Examining past reports, corrective action, and compliance records can be overwhelming.

- Time constraints: Conducting and reviewing detailed audits takes time, which can strain resources.

- Inefficient processes: Traditional methods often involve paper-based systems that could be more efficient and easier to scale.

How FoodReady Revolutionizes Food Inspection and Safety Management?

The food production industry is increasingly turning to technology to overcome challenges related to food safety management. FoodReady offers an innovative software solution tailored to meet food safety and compliance standards. It simplifies the process of managing food inspection reports and overall safety procedures.

Key Features of FoodReady for Food Inspection Management:

1. Automated Compliance Tracking

FoodReady automatically monitors compliance with local, national, and international food safety regulations. This feature helps ensure that businesses get the latest information on law changes, reducing the risk of abuse.

2. Digital Inspection Reports

Replace cumbersome paper processes with digital food inspection reports. Investigators can enter their findings directly into the software, where they are organized and stored for easy access and inspection.

3. Real-Time Monitoring

Real-time monitoring of critical food safety parameters such as temperature, humidity, and hygiene practices. It ensures that any potential problems are identified and resolved promptly.

4. Corrective performance management

FoodReady provides a clear roadmap for corrective action when a violation is found. The software includes scheduling and tracking tools to ensure timely resolution.

5. Integrated training modules

Equip your team with the knowledge they need to maintain compliance. The software includes training resources on best practices and regulatory standards.

6. Customizable checklist

Create an inspection checklist tailored to your facility’s unique processes and risks. This will ensure a thorough assessment.

7. Analysis and Reporting

Leverage analytics to identify trends, track recurring problems, and measure the effectiveness of corrective actions. The software creates detailed reports that make inspections easier.

8. Cloud Access

With cloud storage management, you can access food tracking information anywhere and anytime. This feature is especially useful in multi-site operations.

9. Allergy compliance and labeling

Manage allergen information and labeling requirements to ensure products meet consumer safety standards and legal obligations.

Benefits of Using FoodReady for Food Inspection and Safety Management

- Increased efficiency: Automating audit and compliance processes saves time and reduces administrative burden.

- Better accuracy: Digital systems reduce human error, ensuring accurate data and reporting.

- Improved Compliance: Stay ahead of regulatory changes with automatic updates and compliance checks.

- Cost Savings: Businesses can avoid costly recalls, fines, or lawsuits.

- Streamlined Audits: Easy access to organized reports and documents makes audits less stressful and more efficient.

- Scalability: FoodReady adapts to businesses of all sizes, from small factories to multinational companies

Steps to Implement FoodReady for Your Food Manufacturing Business

- Assessment: Begin with a consultation to assess your facility’s unique needs and compliance requirements.

- Customization: Tailor the software to your processes, risks, and regulatory environment.

- Training: Equip your team with the skills to use the software effectively through training sessions and support.

- Integrations: Connect FoodReady.ai with existing systems for seamless data sharing and workflow management.

- Monitoring: Use real-time data and analytics to track compliance and progress.

- Continuous Improvement: Leverage insights from analytics to refine processes and improve safety standards.

Why Choose FoodReady for Food Safety Management?

FoodReady is more than software. It is a comprehensive solution designed to empower food manufacturers to achieve excellence in food safety. Whether you manage a small bakery or a large food processing facility, FoodReady helps simplify compliance and deliver safe, high-quality products to your customers.

Are your food inspection reports audit-ready and easy to manage?

Discover how FoodReady can digitize inspections, streamline compliance, and keep your facility inspection-ready year-round.

Conclusion

Food inspection reports are the cornerstone of food safety management. They provide a clear picture of compliance and areas for improvement. In an industry where accuracy and compliance are paramount, using an advanced tool like FoodReady will enhance your ability to manage food inspections and safety procedures effectively.

With automatic compliance tracking, simplified document management, and actionable insights, FoodReady helps ensure your business remains compliant, effective, and ready for any audit or inspection.

Investing in such technology is not just about regulatory compliance but also about promoting consumer confidence and achieving operational excellence in the food production industry. Book a demo with FoodReady today to stay ahead of compliance challenges and boost food safety compliance!

They play a vital role in ensuring that food businesses follow safety regulations, ultimately keeping consumers safe from harmful food.

They focus on whether businesses meet hygiene standards, follow food safety procedures, and adhere to the necessary regulations.

The inspector will meet with management to discuss their findings and discuss any steps that need to be taken to correct issues.