A BRC (British Retail Consortium) food safety audit sets an international standard for verifying compliance in food production. Auditors conduct this process using a structured questionnaire, and the company is formally audited for adherence to the required standards.

The BRC standard, recognized worldwide, ensures companies maintain high food safety and food quality benchmarks. BRC food is a globally recognized food safety standard and certification program. BRC stands for British Retail Consortium, which established the BRC Global Standard for Food Safety to ensure compliance with UK and EU regulations and to set audit procedures for the industry.

Retailers, food manufacturers, quick service restaurants, and consumer product companies rely on BRC audits for assurance. BRC audits help businesses meet the updated Standard #9 requirements, with BRC issue 9 being the latest version and focusing on safety culture, compliance requirements, and the certification process.

The Global Food Safety Initiative (GFSI) benchmarks BRCGS and other standards as global indicators of excellence. GFSI certification signals strong international food safety practices. Audits may be announced or unannounced, encouraging daily compliance, not just temporary fixes.

BRCGS certification remains highly sought after in retail, manufacturing, and consumer goods industries. Its standards cover distribution, packaging, raw materials, and supply chains. These ensure strict process control and supplier oversight throughout the food supply system, especially in food manufacturing. An accredited certification body performs the certification audits, serving as the official authority responsible for conducting and verifying compliance with BRC standards. They review documents, assess practices, and inspect on-site operations.

Following the audit, they issue reports to confirm compliance. Before the audit, companies should conduct a gap analysis to identify areas for improvement. This preparation strengthens control measures and overall readiness.

Having comprehensive food safety plans and a robust food safety program is essential for audit readiness. A thorough hazard analysis should also be conducted as part of the preparation process. Implementing and continuously improving food safety processes is critical to ensure ongoing compliance. Achieving BRCGS certification provides the following benefits: it boosts your credibility, strengthens customer trust, and protects against food fraud. It positions your brand as a leader in food safety and product integrity.

FoodReady’s expert consultants assist businesses with every step. They perform mock audits, write HACCP plans, and provide BRC and SQF readiness training. They also offer tailored advice, action plans, and support for continuous quality improvement.

Preparing for a BRC audit can feel overwhelming. It requires attention to detail and constant readiness, not just preparation right before an audit. That’s where FoodReady steps in. Our tools, including the AI HACCP builder and mock audit services, reduce the burden on your quality assurance team.

FoodReady also supports other major food safety certifications. We assist with GFSI, GMP, CGMP, and branded audits like those from Costco, Whole Foods, Kroger, Publix, Safeway, H-E-B and Walmart. Whether you’’re navigating compliance or strengthening internal systems, our platform and consultants provide the expertise you need.

Introduction to BRC Audit

A BRC (British Retail Consortium) audit is a comprehensive assessment designed to verify that food manufacturers are meeting the stringent requirements of the BRC Global Standard for Food Safety. This internationally recognized audit evaluates whether a company’s food safety management system is robust, effective, and compliant with industry best practices.

During the audit, every aspect of the food safety plan is scrutinized, from allergen management and proper hygiene practices to process controls and documentation. The BRC audit process ensures that food manufacturers are not only following the BRC standard but are also prepared to avoid contamination and manage risks effectively.

As a benchmark recognized by the Global Food Safety Initiative (GFSI), the BRC audit plays a critical role in upholding food safety standards across the food industry, providing assurance to customers, retailers, and regulatory bodies that food products are produced safely and responsibly.

The BRC Audit Process

The BRC audit process is a detailed, on-site evaluation conducted by a qualified auditor to assess a food manufacturer’s compliance with the BRC standard. The process begins with a review of documented procedures, including food safety and quality management systems, followed by product testing and a thorough self-assessment. The auditor will interview key personnel, such as senior management and employees, to gauge their understanding of food safety protocols and their roles in maintaining compliance.

A comprehensive site inspection is also carried out to verify that facilities, equipment, and operational practices meet the required standards. This rigorous assessment ensures that every aspect of the food manufacturer’s operations aligns with the BRC standard, providing confidence in the safety and quality of their food products.

How to Prepare for a BRC Audit?

Adequate preparation for a BRC audit starts with a solid understanding of the BRC Global Standard and the audit’s specific requirements. A successful audit involves identifying and addressing operational weaknesses before the certification body arrives.

The audit process typically begins with an opening meeting where the scope, agenda, and key personnel are discussed, setting the stage for the audit.

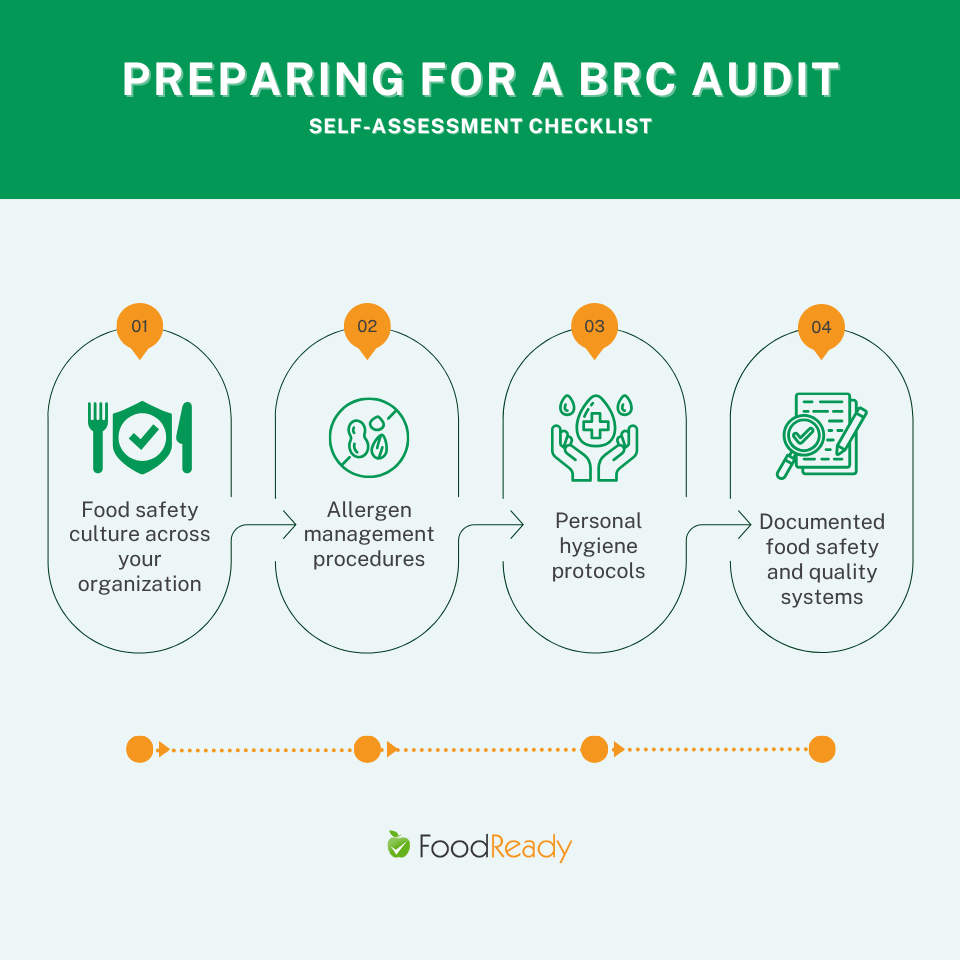

Begin with a thorough self-assessment. This internal review should examine how your current practices measure against the BRC standard, ensuring you are following requirements set out in the BRC standard. Focus areas include:

- Food safety culture across your organization

- Allergen management procedures

- Personal hygiene protocols

- Documented food safety and quality systems

- Internal audit procedures

Once gaps are identified, take action. Develop a corrective action plan to resolve non-conformities and strengthen your systems. Each fix should have a clear timeline, responsible team members, and measurable goals.

Training is another cornerstone of audit success. Ensure all staff are familiar with the BRC standard and your internal policies. Understanding and meeting food safety culture requirements is essential as part of BRC audit preparation. To build confidence and consistency, consider providing:

- Targeted training sessions on food safety culture

- Allergen awareness courses

- Hygiene and sanitation best practices

Aligning your team’s knowledge with global food safety expectations improves audit readiness and operational performance. Proactive planning now leads to smoother audits, fewer surprises, and a higher chance of certification success.

BRC Audit Prep? We Have the Software + the Team.

Let FoodReady’s software and consulting team create your audit roadmap.

Preparing for the BRC Audit: Checklist & Best Practices

Effective preparation for a BRC audit is essential for achieving and maintaining certification. Food manufacturers should begin by thoroughly reviewing the BRC standard and conducting a self-assessment to pinpoint any gaps in their current systems.

Utilizing a BRC audit checklist is a helpful resource, as it highlights the key requirements and focus areas for the audit. Best practices include keeping all documented procedures current and accurate, scheduling regular internal audits to monitor ongoing compliance, and providing comprehensive food safety training for all employees.

It’s also important to ensure that facilities and equipment are well-maintained and meet the necessary standards for food safety and quality. By following these best practices and leveraging a BRC audit checklist, food manufacturers can approach the audit process with confidence, ensuring a successful outcome and upholding the highest standards in the industry.

Maintaining BRC Audit Certification

Maintaining BRC certification requires ongoing commitment. It’s not a one-time achievement but a continuous process to uphold food safety and quality standards. Companies must remain vigilant in updating systems and addressing potential issues proactively.

Key steps to maintain BRC certification include:

- Regularly updating your Food Safety and Quality Management Systems, including your HACCP plan

- Conducting internal and external audits to monitor compliance and uncover improvement opportunities

- Providing ongoing training to all personnel on current procedures and updated food safety standards

- Referencing resources like the BRCGS Food Safety Standard and the Gluten-Free Certification Program to guide updates

When audits reveal non-conformities, companies must:

- Take prompt corrective actions

- Document improvements and preventive measures

- Demonstrate a proactive approach to continuous improvement

It is essential to review audit results to identify areas for improvement and ensure all findings are addressed. After corrective actions are taken, the closing meeting serves as the formal conclusion of the audit, where the auditor presents findings and outlines the next steps for certification.

For continuous improvement, referencing the previous audit helps guide ongoing updates and compliance strategies, ensuring lessons learned are incorporated into future practices.

By actively maintaining certification, companies protect their reputations, ensure consistent product safety, and retain access to major retailers and brand partners.

The British Retail Consortium supports certified businesses through:

- Routine audit services

- Specialized training courses

- A suite of certification programs tailored to evolving industry needs

Staying certified means staying competitive and trusted in the global food market.

FAQs

BRC Standard #8 is the previous version of the BRC Global Standard for Food Safety, focusing on a comprehensive framework for ensuring the production of safe food. BRC Standard #9, published in August 2022, builds on this foundation with updated requirements and best practices reflecting the latest trends and technologies in food safety. It likely includes more rigorous standards for emerging risks, enhanced traceability systems, and stronger emphasis on culture and food safety management systems.

BRC audits are typically conducted annually, but the frequency can vary based on the certification body’s requirements and the previous audit’s outcomes. Unannounced audits are also part of the BRC’s approach to ensure continuous compliance and readiness among certified entities.

The preparation time for a BRC audit can vary greatly depending on the existing level of compliance with the BRC standards, the complexity of the food safety management system, and the size of the operation. Companies new to the BRC standards may need several months to a year to prepare, whereas those with established systems might require less time to ensure they meet the latest standards and requirements.

If you don’t meet some of the crucial requirements, you can fail the BRC audit. Some of the most common mistakes that lead to a low score or a failed audit are hygiene-related ones.