HACCP stands for hazard analysis and critical control points. A food safety plan helps you identify potential hazards in your operation, determine the controls you need to prevent or minimize those hazards, and verify that those controls are working as intended. Using a HACCP plan makes it easier for your food business to identify, prevent and manage food safety risks in your production process. A CCP is any point in a process where something could go wrong (like spoilage) because of the way you handle food products.

This article will explain Critical Control Points (CCPs), how to identify them in a HACCP plan, and why they are essential to maintaining food safety in your business.

What Is a HACCP Plan, and Where Do Critical Control Points Fit In?

A HACCP plan is a documented system that pinpoints the steps in your operation where food-safety hazards must be controlled. Those steps are called Critical Control Points (CCPs): specific moments where a mistake could let a hazard slip through and reach the consumer.

CCPs focus on prevention, not after-the-fact detection. By asking where, why, and how hazards could arise, you evaluate your workflow, identify the most likely trouble spots, and set measurable controls before problems develop. In short, the strength of any HACCP plan rests on the CCPs you choose and manage.

When determining which steps qualify as CCPs for your business, consider all factors influencing food safety, from raw-material risks to processing conditions and final-product use. The right CCPs, correctly monitored, minimize the risk of foodborne illness and protect your customers and brand.

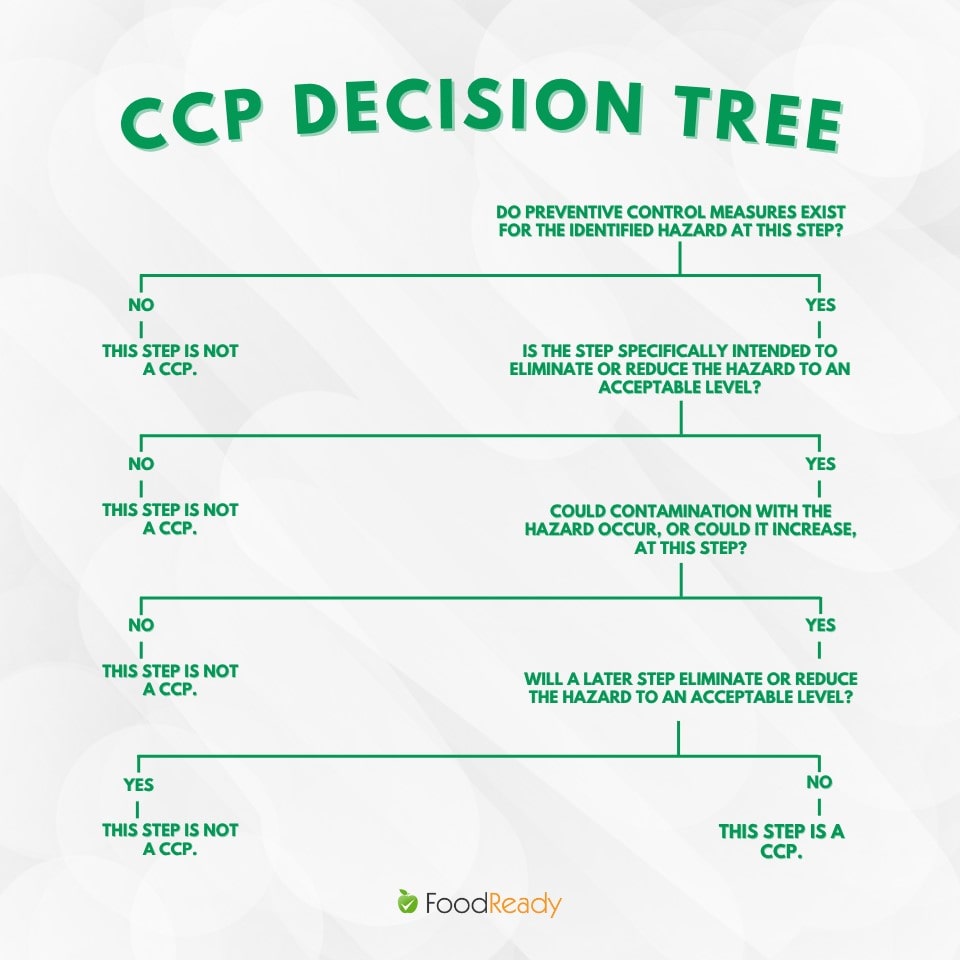

Identifying Critical Control Points Using the CCP Decision Tree

Once you understand what a Critical Control Point is, the next step is determining if a process step qualifies.

That’s where the CCP decision tree comes in.

The CCP decision tree is a structured series of yes-or-no questions used during hazard analysis. It helps food safety teams evaluate whether a specific step is critical to controlling a hazard. While not always required, the decision tree is a widely accepted method used in HACCP plans worldwide.

Here’s a simplified version of the four-question CCP decision tree:

- Do preventive control measures exist for the identified hazard at this step?

→ If no, this step is not a CCP. - Is the step specifically intended to eliminate or reduce the hazard to an acceptable level?

→ If no, this step is not a CCP. - Could contamination with the hazard occur—or could it increase—at this step?

→ If no, this step is not a CCP. - Will a later step eliminate or reduce the hazard to an acceptable level?

→ If no, then this step is a Critical Control Point.

This logical tool ensures that only the most essential steps are classified as CCPs, allowing for tighter monitoring and focused control where it matters most.

What Critical Control Points Do Not Include?

While Critical Control Points (CCPs) play a crucial role in controlling food safety hazards, it’s essential to recognize that not all food safety measures qualify as CCPs.

A CCP is a step at which control can be applied and is necessary to prevent, eliminate, or reduce a food safety hazard to an acceptable level. However, many activities that support a safe food environment fall outside this definition.

CCPs do not include:

- Employee training programs: They are essential for consistency, but are not a direct point of hazard control.

- Routine sanitation procedures are part of your facility’s foundational hygiene practices, not specific hazard eliminators.

- Supplier certifications or audits: While necessary for verifying incoming material quality, they do not represent a control step within your process.

- Traceability systems: Important for recalls and documentation, but not a point where hazards are actively managed.

- Visual quality checks: Attributes like appearance or texture are product quality concerns, not food safety measures.

These types of controls are known as Prerequisite Programs (PRPs). They establish the baseline conditions needed for a functioning HACCP plan, but are not considered Critical Control Points.

Clarifying this distinction strengthens your HACCP plan, improves audit readiness, and ensures monitoring efforts are focused where they matter most.

Examples of Common CCPs in the Food Industry

While the specific Critical Control Points in a HACCP plan depend on the product, process, and facility, certain CCPs are commonly used across various food industry segments.

Below are examples that illustrate how CCPs are applied in different food processing environments:

| Industry | Example CCP | Why It Matters |

|---|---|---|

| Meat processing | Final cooking step | Destroys pathogens such as E. coli, Salmonella, and Listeria. |

| Bakery | Metal detection before packaging | Identifies and removes physical hazards like metal fragments. |

| Beverage bottling | Pasteurization of juice | Eliminates microbial contaminants that can survive bottling. |

| Fermented foods | pH control during acidification | Prevents the growth of Clostridium botulinum. |

| Ready-to-eat salads | Wash water chlorination | Reduces surface contamination on fresh produce. |

These examples show how CCPs are targeted to control specific hazards that cannot be adequately addressed by prerequisite programs alone. Each CCP is selected based on the severity and likelihood of a food safety risk at that point in the process.

More Examples of Critical Control Points (CCPs) Across the Food Industry

While cooking, pH adjustment, and metal detection are some of the most familiar examples, many other steps in food production can serve as Critical Control Points. Below is a structured breakdown of additional CCPs by food category and processing stage, showing how each plays a crucial role in preventing, eliminating, or reducing hazards.

| Industry Sector | Example CCP | Hazard Controlled | Why It Matters |

| Poultry and Meat Processing | Cooking chicken to an internal temperature of 165°F (74°C) | Biological – Salmonella, Campylobacter | Ensures pathogens are destroyed through proper heat treatment. |

| Chilling cooked meats below 40°F (4°C) within two hours | Biological – Bacterial growth | Prevents the rapid multiplication of bacteria during cooling. | |

| Dairy Processing | Pasteurization of milk at 161°F (72°C) for 15 seconds | Biological – Listeria, E. coli | Eliminates harmful microorganisms before packaging. |

| pH control in cheese fermentation | Biological – Pathogen inhibition | Ensures acidity levels prevent microbial survival. | |

| Seafood Processing | Freezing fish intended for raw consumption at -4°F (-20°C) for at least seven days | Biological – Parasites | Kills parasites and ensures product safety for sushi and sashimi. |

| Bakery and Cereal Production | Metal detection before packaging | Physical – Metal fragments | Prevents contamination from broken machinery components. |

| Moisture control in baked goods | Biological – Mold growth | Maintaining proper water activity prevents spoilage. | |

| Beverage and Juice Manufacturing | Pasteurization and heat treatment | Biological – Spoilage organisms | Destroys pathogens and extends shelf life. |

| Filtration and microbial testing before bottling | Biological – Yeasts, molds, bacteria | Ensures microbial stability in the finished product. | |

| Produce and Salad Processing | Wash water chlorination at controlled concentrations | Biological – E. coli, Salmonella | Reduces surface contamination on raw produce. |

| Temperature monitoring during cold chain distribution | Biological – Bacterial growth | Maintains safe storage and transport conditions. | |

| Ready-to-Eat Foods | Allergen control through validated cleaning between product runs | Chemical – Allergen residues | Prevents cross-contact with allergenic ingredients. |

| Final product pH verification | Biological – Pathogen inhibition | Confirms that acidity levels remain within safe limits. | |

| Frozen Food Manufacturing | Rapid cooling from 135°F (57°C) to 41°F (5°C) within a set time frame | Biological – Spore-forming bacteria | Inhibits spore formation and ensures product integrity. |

What is a Food Safety Hazard or Biological, Chemical or Physical Agent?

A food safety hazard is a biological, chemical, or physical agent in, or added to food that may cause illness or injury. Food safety hazards can be natural or man-made. They are present either in raw materials, ingredients, the environment, and/or the processing environment.

Food safety hazards can be a result of:

- The organisms (bacteria) causing illness through poisoning (pathogenic bacteria) and infections (non-pathogenic bacteria). These pathogens include Salmonella, E. coli and Campylobacter.

- Poisonous plants like mushrooms that grow on trees as well as poisonous fish such as puffer fish contain tetrodotoxin which is lethal when consumed by humans with no antidote available to neutralize its effects once ingested!

Critical Control Point Examples in Food Production: Identifying and Managing a CCP

A common example of a critical control point (CCP) in a food production facility is the cooking step in preparing A typical example of a Critical Control Point (CCP) in food production is the cooking step for ground beef patties. Ground beef is especially susceptible to contamination with pathogens such as E. coli O157:H7. To eliminate this risk, a facility might designate a minimum internal temperature of 160°F (71°C) as a critical limit. Operators must verify this temperature using calibrated thermometers for every batch. If patties do not reach the required temperature, they must be recooked or discarded. This CCP ensures that harmful microorganisms are effectively destroyed before the product reaches consumers.

CCPs are not limited to thermal processing. They also apply to any step where a breakdown in control could lead to contamination. For example, the contamination risk is no longer managed if raw chicken is dropped on the floor and returned to storage without proper cleaning and sanitizing. Bacteria such as Salmonella can be transferred via hands, clothing, or contact surfaces to other products, potentially making consumers ill. In this case, the failure wasn’t simply poor hygiene; it was a missed opportunity to control a known hazard at a critical point in the process.

These examples highlight why CCPs must be clearly defined, consistently monitored, and strictly enforced to prevent foodborne illness and ensure regulatory compliance.

Ready to Identify Your CCPs with Confidence?

Use FoodReady’s AI-powered HACCP builder to map out Critical Control Points with precision and ease.

CCP vs. PRP vs. Quality Control: Quick Reference Table

In a HACCP system, it’s essential to distinguish between different types of controls. While all contribute to food safety or product quality, only Critical Control Points (CCPs) control significant hazards within the process.

This table provides a quick reference to help clarify those roles:

| Type | Purpose | Example | Is it a CCP? |

|---|---|---|---|

| CCP (Critical Control Point) | Prevent or eliminate food safety hazards | Cooking, pH adjustment, and metal detection | Yes |

| PRP (Prerequisite Program) | Maintain basic hygiene and operational conditions | Cleaning, sanitation, and employee training | No |

| Quality Control Check | Ensure the product meets brand or customer expectations | Texture check, labeling accuracy | No |

Understanding these categories helps you build a more precise and effective food safety plan. It also supports better compliance during inspections and audits by showing that you know where to focus your control and monitoring efforts.

Conclusion

Understanding and identifying Critical Control Points (CCPs) is fundamental to implementing an effective HACCP plan. By proactively monitoring key stages in your food production process where hazards can be controlled or eliminated, your facility enhances food safety, reduces risk, and ensures regulatory compliance. Whether it’s managing cooking temperatures, preventing cross-contamination, or verifying sanitation procedures, CCPs serve as the backbone of a preventive food safety system.

A well-designed HACCP plan, supported by clearly defined CCPs, not only protects consumer health but also reinforces brand trust and operational integrity. As the food industry continues to evolve, staying vigilant and data-driven in your approach to hazard analysis and control remains essential for long-term success.

FAQs

Bacteria and other pathogens that are heat or cold sensitive are controlled during a “kill step” where food temperature or other factors like acidity are controlled. Learn more about kill steps.

The most commonly used control in a critical control point is cooking.

Common CCPs include temperature control during cooking and cooling processes, pH control for acidification, allergen management, metal detection, and microbial testing.

The frequency of monitoring must be specified in the HACCP plan and should be based on the severity of the hazard, production volume, type of food, type of equipment used, etc. Generally speaking, CCPs need to be monitored at least once every four hours during continuous operations and after each batch processing.

The HACCP team should designate who in the organization will be responsible for monitoring the CCPs. The person or persons assigned to monitor CCPs must have the necessary skills and knowledge to carry out their duties effectively.

If a CCP is not being met, the HACCP team should perform an immediate corrective action to address the issue. This might involve adjusting processing parameters or rejecting the product until it meets safety standards. The corrective action should be documented and reviewed by the HACCP team to ensure that no further hazards occur.

Cooking chicken to an internal temperature of at least 165°F (74°C) ensures that harmful bacteria such as Salmonella are destroyed, making the product safe for consumption.

Critical limits are the maximum or minimum values that must be met at a Critical Control Point (CCP) to prevent, eliminate, or reduce food safety hazards to an acceptable level.

Adhering to established critical limits and documenting monitoring activities provides evidence of compliance with regulatory and certification requirements during audits and inspections.

Maintaining food at or below 40°F (4°C) prevents bacterial growth, while cooking or reheating above required temperatures ensures pathogens are destroyed.

Keeping water activity below 0.85 in shelf-stable foods prevents most bacteria from growing, which helps extend product shelf life and maintain safety.

Critical limits are set by identifying measurable parameters at each CCP, such as temperature, time, pH, or water activity, and ensuring they are scientifically validated to control the identified hazard.

A critical limit must be practical for real-time monitoring, directly linked to controlling the hazard, and quantifiable so operators can verify compliance during production.

Yes. A single Critical Control Point may require more than one critical limit, for example, both temperature and time controls, to ensure complete hazard reduction.

Critical limits must be grounded in scientific evidence, regulatory standards, or industry best practices to ensure they are defensible and effective during audits or inspections.

Quickly cooling cooked food from 135°F (57°C) to 41°F (5°C) within a defined timeframe prevents spore-forming bacteria from multiplying, helping maintain food safety and product integrity.