In the early days of manufacturing automation, material requirements planning (MRP) transformed businesses’ approach to food production.

Decades later, MRPs evolved into strategic engines that help food manufacturers reduce waste, avoid costly shortages, and synchronize production with real-time demand.

Whether you’re producing craft beverages, ready-to-eat meals, or frozen snacks, an effective MRP system ensures your operations run like clockwork, even when the supply chain doesn’t.

In this guide, I’ll cover everything you need to know about MRP in the food and beverage world, from its meaning and evolution to how it works in food manufacturing.

What Is Material Requirements Planning (MRP)?

Material Requirements Planning, or MRP, is a system that helps food manufacturers plan, schedule, and manage inventory and production processes.

Its core goal is to ensure materials and products are available for timely production and delivery, minimize stockouts and overstocking, and streamline production.

Food MRP answers three essential questions:

- What materials are needed?

- How much of them is required?

- When are they needed?

How Does MRP Work in Food Manufacturing?

In food and beverage, material requirements planning (MRP) helps ensure the right ingredients are available at the right time without overstocking or missing production deadlines.

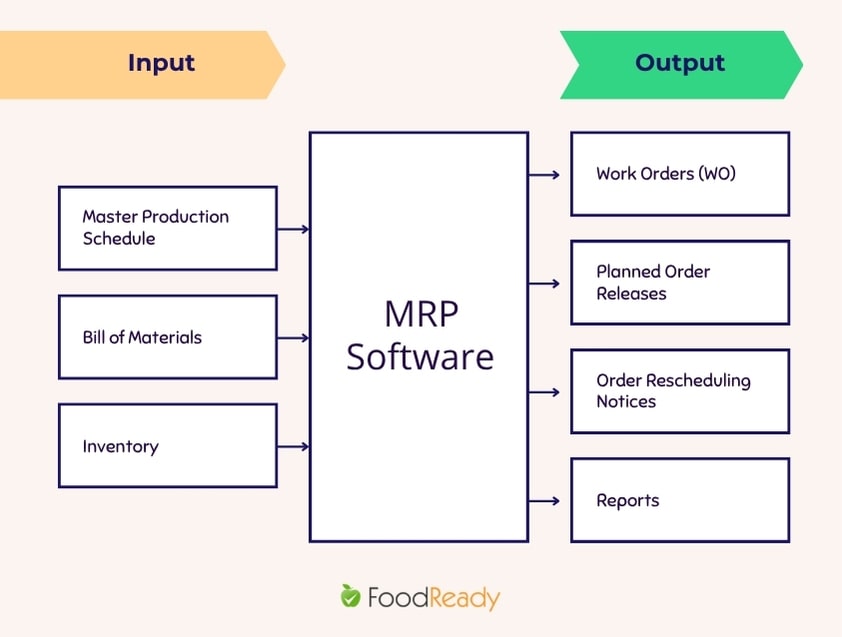

The process begins with three core MRP inputs:

- Master Production Schedule (MPS). It outlines what finished products must be produced, the quantities, and the deadline.

- Bill of Materials (BOM). BOMs list items that must be purchased, indicate their quantity, and when they must be ordered.

- Inventory: Inventory records provide a real-time overview of what’s in stock, including raw ingredients, packaging materials, work-in-progress items, and even finished goods.

The system then “explodes” the BOM to calculate total material needs, subtracts available stock, excluding near-expiry items, and schedules procurement and production based on lead times.

Key outputs of the MRP process include:

- Work Orders (WO): MRP gives the instructions for the production floor to manufacture specific quantities, mentioning the required materials and timelines.

- Planned Order Releases: The MRP details what materials are needed, in what quantities, and when they should be ordered or produced.

- Order Rescheduling Notices: MRP can ask to adjust existing orders to respond to changes in demand forecasts or inventory levels.

- Reports that include exception reports highlighting discrepancies, performance reports analyzing key performance indicators (KPIs), and planning reports outlining production schedules, material requirements, and capacity planning.

Apart from that, MRP can provide purchase orders and inventory projections. MRP outputs help food manufacturers manage production schedules, optimize inventory levels, ensure timely material procurement, and adapt to demand fluctuations.

The History of Material Requirements Planning in the Food Industry

Interesting fact: the global MRP software market was estimated at 6.63 billion dollars in 2024 and is supposed to double by 2033. Still, the success story started long ago.

Joseph Orlicky developed and implemented the first MRP system at Black & Decker in the 1960s. However, the system was expensive, difficult to manage, and occupied much space, making it accessible mainly to large corporations.

The food industry was slower in adopting MRP because of its unique challenges, including product perishability, shelf-life management, recipe complexity, and regulatory requirements.

Over time, food manufacturers began customizing MRPs to track expiration dates, manage batches, and reduce spoilage.

These adaptations boosted the development of food-specific features like lot traceability, allergen tracking, and recipe management.

Today, food MRP systems are essential in food manufacturing, as they ensure safety, compliance, efficiency, and sustainability across the entire supply chain.

Why Is MRP Important for Food Manufacturers?

The food manufacturing industry is very regulated and includes specific processes that require much attention.

Manual inventory management is a recipe for disaster in the food industry. Paper logs and spreadsheets can’t keep up with modern production and sales volumes, supplier variability, and regulatory demands.

Here’s how MRP helps maintain compliance and prevent stockouts or overproduction.

1. MRP Enforces FIFO of Ingredients

The FIFO method helps food handlers ensure that older inventory is used before newer stock, minimizing spoilage and ensuring food freshness.

MRP tracks the receipt date or batch code of raw materials and ingredients and automatically prioritizes older inventory in production planning based on expiration or manufacturing dates.

Food MRP also integrates with barcode and lot tracking systems to flag stock that needs to be used first.

This is how MRP helps avoid ingredient waste while maintaining food quality standards.

2. Controlling Shelf Life of Finished Products

Limited product shelf life requires food manufacturers to manage it properly. Products can expire before reaching stores or customers, leading to lost revenue or recalls.

MRP helps manage shelf life dynamically based on production date and product-specific rules. The system also flags batches expiring soon to prioritize them or discount them.

Products with shorter shelf lives will also be shipped first, as MRP synchronizes with sales and distribution planning.

This way, you sell finished products on time, and customers consume them safely.

3. Traceability of Dispatched Stock

FSMA 204 rule requires food businesses to maintain traceability to trace quickly dispatched stock back to its origin in case of a recall.

For this purpose, MRP maintains lot-level traceability for raw materials, work-in-progress (WIP), and finished goods.

It also helps create a transparent audit trail by linking each dispatched unit to a specific production batch and ingredient lot.

Benefits of an MRP System in the Food Industry

Here’s what you can get from a material requirements planning system:

- Enhanced Production Planning. An MRP system allows manufacturers to plan production more accurately, making the right products available at the right time.

- Improved Traceability. As we discussed, MRP is an efficient way to ensure backward and forward traceability.

- Resource and Inventory Optimization. MRP helps you reduce stockouts and overproduction, as you only order what you need and when.

- Process Automation. MRP helps reduce manual tasks and replace them with technologies for more automation and error reduction.

- Streamlined Food Manufacturing Process. MRP provides a holistic view of the operations, enabling better coordination between departments.

- Customer Satisfaction. MRP helps manufacturers consistently deliver high-quality products on time, which builds stronger customer relationships and improves their brand reputation.

The Example of Material Requirements Planning in Action

Imagine a fictional mid-sized juice manufacturing company producing preservative-free cold-pressed juices with a 7-day shelf life. Let’s call it a FictionBev company.

Facing frequent ingredient spoilage, packaging material shortages, and production delays, FictionBev implemented a food and beverage MRP system to streamline operations.

To plan weekly production, for instance, 10,000 bottles of orange juice, the system collected inputs: sales forecasts (MPS), the recipe (BOM), and real-time inventory, including expiration dates.

It calculates required materials, checks real-time stock, excluding near-expiry items, and schedules procurement based on supplier lead times.

The material requirements planning system generates work orders, purchase orders, and rescheduling alerts to align materials and production with demand. It helps reduce ingredient waste, increase on-time production, and improve inventory accuracy.

It also enhances traceability, allowing the company to identify which batches used recalled ingredients. Overall, the MRP system helped our fictional company run more efficiently while maintaining food safety and regulatory compliance.

Best Practices for Successful MRP Implementation

I hope now you want an MRP solution in your organization. But how to implement it? Let’s break down the key aspects contributing to successful MRP implementation and get the most out of it.

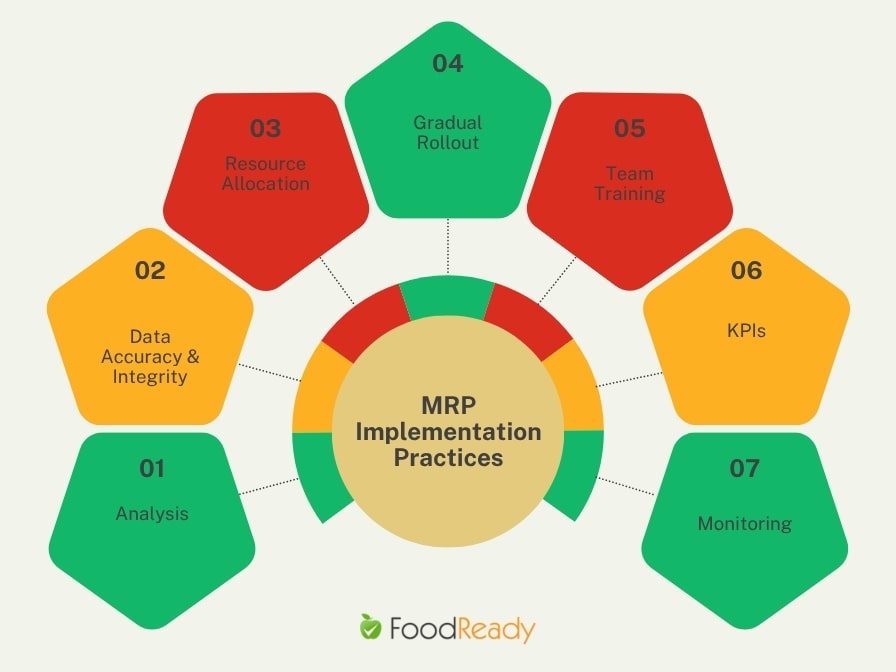

1. Everything Starts With a Needs Analysis

To align MRP software with your goals and challenges, such as perishable inventory and compliance needs, you should thoroughly assess your processes, find the pain points, and highlight the requirements.

2. Ensure Data Accuracy and Integrity

Clean and organize your data. Before migrating to the new system, double-check all inventory, bills of materials (BOM), supplier, and recipe information.

You can implement barcode scanning and regular audits to maintain data integrity, reduce errors, and enhance decision-making.

3. Allocate the Resources

Dedicate adequate budget, time, and personnel to the process. You should assign the task to a professional with experience in MRP systems and involve cross-functional teams to improve collaboration and address department concerns.

4. Work in Phases

Don’t do everything at once. Instead, MRP should be rolled out gradually, starting with the most critical production lines.

This is how you will make manageable adjustments, minimize disruptions, and address arising issues promptly.

5. Train the Team

Professional training is a must to equip your employees with the necessary skills to use the MRP system effectively.

6. Set Clear KPIs

Define your goals and what your progress should look like. For instance, you want to reduce ingredient waste by 15%.

7. Continuous Monitoring

Once you implement the system, monitor its performance and gather user feedback. Use this information to make adjustments, optimize processes, and ensure the MRP system continues to meet your evolving business needs.

Four Food MRP Challenges

The food manufacturing sector presents its requirements and complexities. This makes implementing the material requirements planning (MRP) system more challenging. Let’s see the obstacles you may face.

1. Industry Regulations

The food industry revolves around food safety compliance. Standards such as HACCP and FSMA require MRP systems to integrate documentation and other processes. Following regulatory requirements is critical to avoid penalties and protect consumer health.

2. Perishability and Shelf-Life Management

Unlike non-food products, food often has a limited shelf life, which obliges companies to control inventory precisely to minimize waste and spoilage. MRP systems must account for expiration dates and manage inventory using methods like FIFO (First In, First Out) to ensure product freshness.

3. Complex Recipe and Formula Management

Intricate recipes with multiple ingredients and processing steps are typical for food manufacturing. MRP systems must handle variable formulations, ingredient substitutions, and version control to maintain product consistency and quality.

Read our blog if you want to understand recipe management better.

4. Supply Chain Complexity

The food supply chain involves multiple stakeholders, such as suppliers, manufacturers, distributors, and retailers. MRP systems must be adaptable and capable of handling dynamic changes in supply and demand.

Misconceptions About Material Requirements Planning (MRP)

Misconceptions exist everywhere, but I want to help you understand the real picture of MRP. Let’s look at some theories and discuss if they are true.

Myth 1. It’s only an inventory management tool

MRP is not just a fancy inventory tool. It goes beyond inventory tracking by supporting procurement, production planning, supplier scheduling, etc

Myth 2. MRP doesn’t respond to real-time demand

It can be true for traditional systems, but modern MRP, especially within ERP, can react way more responsively thanks to real-time data integrations and smart automation.

Myth 3. MRP software is only for large enterprises

Cloud-based MRPs have evolved into solutions suitable for small and mid-sized food businesses. Software vendors offer powerful planning tools without needing a whole IT department.

Myth 4. MRP is obsolete because ERP exists

In reality, MRP is a core component of a food ERP system. While the second one handles a broader scope of tasks, MRP copes with inventory control, scheduling, and raw material planning.

Myth 5. MRP doesn’t work for perishable inventory

That’s what we’re proving wrong in this article. Food manufacturers can use MRP to manage food inventory and product demand efficiently.

MRP vs. ERP

Although material requirements planning (MRP) and enterprise resource planning (ERP) may be considered interchangeable, they serve different (but still connected) functions in manufacturing.

I know how confusing it can be when deciding what you need. Let me explain it in more detail.

MRP systems are perfect for production planning and inventory management. They are more standalone systems that can be a part of ERP.

On the other hand, ERP is a broader system connecting core business functions, such as manufacturing, finance, HR, quality control, etc.

Here are some of the key aspects highlighted in both systems to compare:

| MRP (Material Requirements Planning) | ERP (Enterprise Resource Planning) | |

| Scope | Focused on production and inventory planning | Concentrates on core business processes across departments |

| Key Modules | Inventory management, purchasing, production scheduling | Compliance, HR, CRM, inventory, manufacturing, etc. |

| Typical Users | Production planners, procurement teams | Entire company |

| Implementation | Generally simpler and faster to implement | More complex and time-consuming to deploy |

| Cost | Lower initial costs, as it’s a standalone solution | Higher costs but more features |

| Data Integration | The focus is on manufacturing data | Centralized data overview across the departments. |

MRP or ERP System: What To Choose?

The answer to this question will depend on your needs and business focus. If you need a tool for food manufacturing, production scheduling, inventory control, etc., you might benefit more from MRP.

On the other hand, if you want to cover the whole company’s operations, food ERP software will be better for you.

Not sure which one you need?

Book a strategy call with our MRP/ERP specialists and get clarity.

FoodReady MRP Software for the Food and Beverage Industry

Staying ahead of demand while managing inventory, raw materials, and production schedules is a constant challenge in the fast-paced food industry. Still, MRP software can drive real change and transform your approach.

FoodReady MRP software is designed by food industry experts for food and beverage manufacturers. It understands the industry’s unique requirements, such as food safety compliance, batch production, expiration tracking, or allergen segregation.

Why is FoodReady the right option for you?

The platform offers various features, including ingredient-level planning, recipe and batch management, real-time inventory control, production scheduling, and compliance support.

We’re user-friendly, so your staff will learn the ropes quickly. The intuitive interface makes the user experience easy and stress-free. Moreover, you can feel safe as FoodReady offers full-time customer support to help you out.

FoodReady is a customizable solution that is ready to scale with your business. The software integrates with other platforms and ERP modules if you need more.

Book a demo to see the full FoodReady MRP functionality and benefits for you!

Shaping the Future of Food Manufacturing with MRP

Despite the industry specifics, MRPs evolved into a comprehensive system that helps food manufacturers plan, schedule, and manage inventory and production processes efficiently.

MRPs enforce the FIFO method, help control the shelf life of perishable products, and trace dispatched stock, resulting in multiple advantages, from improved production planning to customer satisfaction.

Still, double-check whether you need a material requirements planning solution or the whole ERP system. Our consultants can help you figure it out.

At FoodReady, we combine deep regulatory knowledge with intuitive tools that simplify compliance, scheduling, and inventory control.

Are you interested in learning more or seeing FoodReady in action? Request a demo to start your MRP journey.

FAQs

MRP II stands for manufacturing resource planning. It’s an extension of an MRP system that adds capacity planning, shop floor control, financial planning, and labor scheduling.

Demand-driven MRP (DDMRP) is a modern planning method that combines traditional MRP with lean principles and real-time demand signals. Instead of planning based only on forecasts, DDMRP uses actual demand to trigger replenishment.

The method is built on five pillars that buffer demand variability and improve supply chain responsiveness:

1. Strategic Inventory Positioning

2. Buffer Profiles and Levels

3. Dynamic Adjustments

4. Demand-Driven Planning

5. Visible and Collaborative Execution

It is suitable for highly variable or fast-moving food manufacturing environments, as it helps reduce inventory, lead times, and the “bullwhip effect” when small shifts in demand cause larger disruptions.

Both terms are mostly interchangeable. The slight difference is that MRP software refers specifically to the digital application or tool. In contrast, the MRP system can refer more broadly to the entire planning framework, including the software, processes, inputs, and team.

Food material requirement planning will benefit small and large food manufacturers, distributors, warehouses, and restaurants.

You might also need MRP if you work in a procurement, production, inventory management, or quality control department.