In the food safety world, the margin for error is razor thin. One small oversight, whether in compliance, training, or traceability, can lead to recalls, reputational damage, or public health crises. Yet many food businesses struggle to pinpoint where their systems fall short until it’s too late. This is where gap analysis becomes invaluable.

By offering a straightforward method to evaluate current operations against regulatory or performance standards, gap analysis helps food safety professionals uncover blind spots, prioritize risks, and take focused action.

This article walks you through how to apply gap analysis to drive continuous improvement in your operations, ensuring your facility stays compliant, competitive, and consumer safe.

Introduction to Gap Analysis

Gap analysis helps companies identify the space between their current performance and future goals. Businesses analyze internal and external factors that influence performance. This process shows teams where they stand and where they need to go. It offers a clear path forward. Strategic teams use gap analysis to find weak points. Then they build effective plans to close those gaps and improve. Tools like SWOT and PEST analysis can support this process and add depth to findings.

Understanding the Current State

Your current state shows how your business performs right now. This includes customer feedback, financial records, and market share.

You must collect data from various sources, including surveys, industry benchmarks, and internal reports. By reviewing this information, you can highlight strengths and expose weaknesses. You must know where you stand before you plan to move forward.

Evaluating current operational processes, workforce capabilities, and customer experience metrics gives insight into your baseline.

When Should You Conduct a Gap Analysis?

Gap analysis is most useful during periods of transition, such as:

- Launching a new product or service

- Preparing for audits or shifting strategies

- Rebranding or restructuring

- Experiencing stagnation or performance decline

You should also perform one when facing performance issues or planning for future growth. Timing matters.

Choose moments when data is available and leadership is ready to act.

Defining Desired States

The desired state defines what the business wants to achieve. These goals include better customer satisfaction or higher profits.

Set clear, specific, and realistic goals. Use measurable targets that align with business priorities; factor in external influences like market trends and internal aspects such as team culture and available resources. Well-defined goals drive direction and help teams stay focused.

Consider a food packaging company aiming to reduce contamination complaints by 40%, a concrete, measurable target aligned with operational capacity and brand promise.

When setting your targets, factor in external influences like market trends and internal variables such as team culture, budget, and training levels. Engaging cross-functional leaders in this step ensures broader buy-in and more explicit expectations.

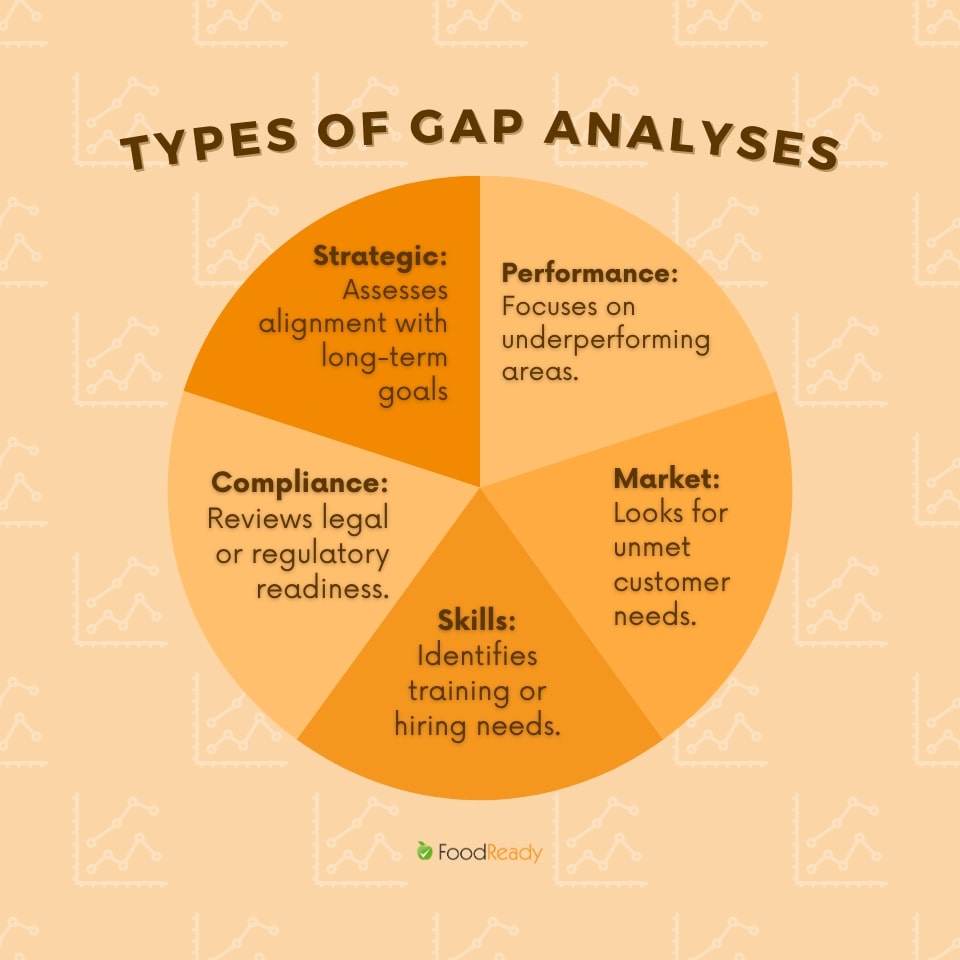

Types of Gap Analyses

Gap analysis applies to different business needs:

- Strategic gap analysis assesses alignment with long-term goals

- Performance gap analysis focuses on underperforming areas.

- Market gap analysis looks for unmet customer needs.

- Skills gap analysis identifies training or hiring needs.

- Compliance gap analysis reviews legal or regulatory readiness.

Knowing the type helps tailor your process.

Each type has its tools and data sources, so choose based on what you need to improve.

Conducting Gap Analyses

Start your gap analysis by comparing the current state with your desired outcome.

Review your performance.

Check if you meet your targets.

If not, find out why. Use SWOT analysis to uncover strengths and weaknesses.

PEST analysis can help assess external threats and opportunities. Apply this method across various functions such as customer satisfaction, financials, or operations. Repeat the process regularly to stay aligned with evolving goals. Internal stakeholders are consulted during this step to validate assumptions and refine findings.

Fundamental Components

Every gap analysis includes three elements: current state, desired state, and the gap between. You must review your data. Focus on both internal practices and external market conditions. Identify what you’ll need to move forward—people, tools, budget, or training. Use these parts to build a thorough and practical analysis. These components also form the foundation of strategic reports and action plans.

| Component | Description |

| Current State | Evaluates present performance through data such as customer satisfaction, financials, and operations. |

| Desired State | Defines future goals, including targets like market share, customer feedback, or process improvements. |

| The Gap | Identifies discrepancies between current and desired performance and outlines needed resources. |

Identifying Gaps

Look at where your company falls short. These gaps show what’s holding you back. Apply tools like SWOT or PEST to sharpen your understanding. Collect updated records, customer surveys, and market performance data. Rank these gaps by importance. Address the most critical ones first. Use visual mapping techniques or dashboards to communicate findings across departments.

One practical example? Munot Plastics, a thermoformed packaging manufacturer, needed to tighten its food safety documentation. They weren’t operating poorly, but the gap between good and audit-ready was widening. Their internal review surfaced inconsistencies in recordkeeping and unclear SOP ownership. Once these were charted, their team could prioritize fixes instead of scrambling under pressure. With the help of a FoodReady consultant and customized digital tools, they closed those gaps and passed their next audit with zero findings. That clarity doesn’t come from guessing; it comes from knowing where you stand.

Need Help Spotting Operational Gaps?

Let a FoodReady expert walk you through a gap analysis tailored to your facility’s needs.

Common Challenges in Gap Analysis

Some teams struggle with vague goals or incomplete data. Others rush the process or skip stakeholder input. To avoid these issues:

- Clarify your objectives early.

- Involve all key departments.

Conduct stakeholder interviews. - Cross-reference with historical data and trends.

Review past projects for lessons learned. Real progress requires honesty and collaboration.

Business Goals and Gap Analysis

Use gap analysis to move closer to your goals. It maps the space between where you are and where you should be. This method highlights performance problems, market weaknesses, or missing resources. SWOT and PEST tools offer insights for deeper analysis. Gap analysis guides your strategic planning and keeps your team focused. It ensures actions remain tied to clear business outcomes and measurable milestones.

Developing an Action Plan for Gap Analysis

Once you’ve found your gaps, develop a plan to close them. Outline steps, assign responsibilities, and estimate the resources you’ll need.

Make each action SMART:

- Specific

- Measurable

- Achievable

- Relevant

- Time-bound.

Continue tracking progress. Adjust the plan if necessary. Integrate checkpoints or reviews to keep momentum strong and redirect when necessary. Our food safety plan templates can help shape a solid strategy if you’re starting from scratch.

How to Use a Gap Analysis Template?

Templates streamline the process. Most include columns for current state, desired state, the gap, and proposed actions. Customize the template to your business. Fill it in during team workshops or planning sessions. Templates keep everyone aligned and make reporting easier. Consider digital versions for real-time collaboration.

1. Future State Considerations

To define your future state, consider what success means for your business. Study market trends, customer needs, and your internal performance. Set realistic expectations. Use tools and templates to organize your insights. These steps help you build a strategic roadmap to guide your team. Consider external disruptions like regulations or tech shifts while outlining future goals.

2. Bridging the Gap

Create a timeline to close the gap between your current and future states. Assign tasks, track progress, and gather metrics for accountability. Use frameworks like McKinsey’s 7S to evaluate key areas such as strategy, systems, skills, and staff. Evaluate often. As goals shift, so should your plans. Stay flexible. Regular review helps teams keep up with change and meet targets.

FoodReady can support this process by helping you organize tasks, monitor compliance milestones, and maintain a digital record of corrective actions. Its customizable tools streamline evaluations, simplify documentation, and ensure your team stays aligned with regulatory expectations and strategic objectives. Reinforce this process through regular training and celebrating milestones as you achieve them.

Conclusion

Gap analysis isn’t just a business exercise; it’s a practical tool for driving targeted improvement in high-stakes industries like food safety. By systematically comparing where you are with where you want to be, your team can identify blind spots, reallocate resources effectively, and build a clear, measurable path forward. Whether seeking compliance with new regulations, improving internal performance, or preparing for audits, a structured gap analysis keeps your strategy grounded in data and aligned with your goals. In the food industry, where safety and precision are everything, closing the proper gaps can make all the difference.

FAQs

A gap analysis helps you identify the differences between your current performance and desired goals. It’s used to uncover inefficiencies, assess resource needs, and guide strategic planning.

In food safety, gap analysis helps facilities identify compliance issues, training gaps, or process weaknesses that could lead to contamination, audit failures, or recalls.

Standard tools include SWOT (Strengths, Weaknesses, Opportunities, Threats), PEST (Political, Economic, Social, Technological) analysis, and the McKinsey 7S Framework. Templates and digital checklists also streamline the process.

Conduct a gap analysis during any significant transition, new product launches, regulation changes, audit prep, or at least once yearly to align your strategy with industry standards.

Absolutely. Small and midsize businesses often benefit the most, as gap analysis clarifies and prioritizes environments with limited time, staff, or resources.