In a world where food security and safety are paramount concerns, the significance of proper food storage and transportation practices cannot be overstated. Every year, a staggering amount of food is lost or wasted due to inadequate handling, storage, and transport methods.

This not only worsens hunger and environmental issues but also poses serious health risks. Ensuring proper food storage and transportation is essential for public safety, as it helps keep food fresh, uncontaminated, and safe for consumers. In this blog, you’ll learn about the crucial practices and innovations shaping the landscape of food storage safety and food safety during transportation, with a focus on the need to avoid contamination as a core goal of best practices.

Why Is Food Storage and Transportation Safety Important?

Unsafe food containing harmful bacteria, viruses, parasites, or chemical substances causes more than 200 diseases, ranging from diarrhea to cancer.

According to the World Health Organization (WHO), an estimated 600 million – almost 1 in 10 people in the world – fall ill after eating contaminated food, and 420,000 die every year.

Even small temperature fluctuations, poor hygiene, or careless handling can spoil food products and cause contamination.

This is especially true for perishable foods such as meat, dairy, and seafood. Strengthening every step of the food transport process helps prevent safety issues, protect product safety, and maintain compliance across the supply chain.

- Operational costs: Spoiled or contaminated shipments lead to product loss, fines, and transportation inefficiencies.

- Public health: Improper transport and storage can cause bacteria to multiply rapidly, increasing the risk of foodborne illnesses such as Listeria, Salmonella, or E. coli.

- Brand reputation: One food safety incident is enough to erode consumer trust. Safe storage and delivery practices build confidence and loyalty.

What Are the Types of Food Transportation?

Different foods have unique needs when it comes to transportation. Understanding the right method for each product helps reduce food safety risks and ensure compliance with food safety requirements. Choosing the appropriate way to transport food is essential for moving food products safely and maintaining their quality throughout the supply chain.

- Dry Goods Transport is used for non-perishable foods such as canned goods, grains, flour, and packaged snacks. These items travel best in clean, dry, and pest-free trucks or containers where humidity and temperature are controlled to prevent spoilage.

- Refrigerated and Frozen Transport is great for perishable items like dairy products, meats, seafood, and frozen meals. These vehicles are specifically designed to maintain cold or freezing temperatures for perishable goods and are temperature controlled to prevent spoilage, ensuring food safety and quality during transit.

- Hot Food Delivery is commonly used in catering, foodservice, and meal delivery operations. Cooked or ready-to-eat meals are transported in insulated carriers or hot-holding units with temperatures above 135°F (57°C) to keep the food safe until it’s served.

- Bulk liquid transport is used for beverages, edible oils, syrups, and other liquid food ingredients. These are transported in sealed, food-grade tanks or containers that prevent leaks, contamination, and exposure to external elements.

What Are the Food Storage Types?

Each food category requires specific storage conditions. Let’s take a look at what storage types fit best for the food you make:

- Dry Storage: Ideal for items that don’t require refrigeration, such as grains, pasta, canned foods, and baking ingredients. These should be kept in clean, cool, and moisture-free spaces with proper airflow.

- Chilled Storage: Used for storing perishable foods, including dairy products, meat, and fresh produce. Temperatures just above freezing keep bacteria from multiplying while preserving taste and texture.

- Frozen Storage: Ideal for foods that require long-term preservation, such as seafood, frozen meals, and meat. Keeping temperatures below freezing preserves quality and stops microbial growth.

- Controlled Atmosphere Storage: Common for fresh fruits, vegetables, and certain packaged goods. The air composition inside the storage area is adjusted to extend shelf life and slow ripening.

- Heated or Hot Holding Storage: Designed for cooked or ready-to-eat meals that require maintaining a hot temperature until serving. It’s essential for preventing bacteria from growing in prepared foods.

- Liquid or Bulk Ingredient Storage: Used for storing products such as oils, beverages, or syrups in large, sealed, food-safe containers or tanks to prevent contamination and maintain purity.

What Are the Common Issues When Storing and Transporting Food?

While food businesses understand hygiene in kitchens, they often overlook transit challenges:

- Temperature Control: Perishable foods must remain in the “safe zone” (usually between 40°F and 140°F). A brief lapse in temperature control during a hot summer delivery can lead to bacterial growth and spoilage.

According to the CDC’s latest analysis, time–temperature control failures remain one of the main causes of foodborne outbreaks. 13,1% of cases were linked to foods left out of proper temperature control during preparation, while another 11,5% occurred during food service or display.

- Cross-Contamination: Shared vehicles, unsealed or damaged containers, and poor segregation between raw food and ready-to-eat items can spread pathogens and allergens

- Vehicle Hygiene: Dirty cargo areas, rodent infestations, or leftover spills can silently contaminate food shipments, which poses a significant risk to food safety. Keeping vehicles clean through routine cleaning and maintenance is crucial to prevent contamination and maintain hygiene standards.

- Documentation and Tracking: The absence of real-time monitoring systems or data loggers makes it difficult to identify issues when they arise.

Best Practices in Food Storage Safety

Proper food storage controls temperature, packaging, and hygiene to prevent contamination and maintain product quality. These practices keep foods safe and extend their shelf life during handling and transport.

- Temperature Control:

- Refrigeration and Freezing: Keeping food at the right temperature is vital. Perishable goods, such as dairy, meat, and seafood, require refrigeration at or below 40°F (4°C) and freezing at 0°F (-18°C).

- Dry Storage: Non-perishable items, such as grains and canned foods, should be stored in a cool, dry place, away from direct sunlight and moisture.

- Packaging and Containment:

- Use airtight containers to prevent contamination and extend shelf life.

- Innovative packaging solutions like vacuum packing and modified atmosphere packaging (MAP), help maintain food quality and freshness.

- Cross-Contamination Prevention:

- Separate raw and cooked foods to prevent bacterial transfer.

To learn more about cross-contamination and how to avoid it, read our cross-contamination blog.

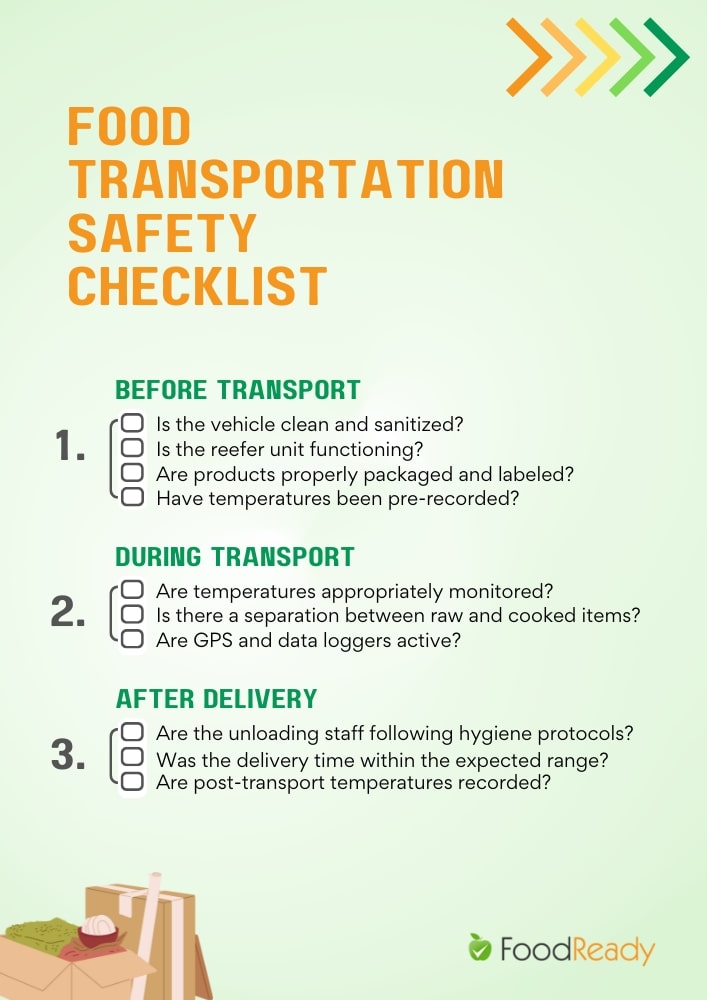

Transporting Food Safely: Key Aspects to Know

- Maintaining the Cold Chain:

- For perishables, it’s crucial to maintain a consistent temperature throughout the journey. GPS-enabled temperature monitoring and IoT (Internet of Things) devices are increasingly being used for real-time tracking.

- Hygiene and Sanitation:

- Vehicles and containers must be regularly cleaned and sanitized to prevent the spread of pathogens and to eliminate any attractants of pests.

- Drivers and handlers should be trained in proper hygiene practices.

- Vehicles used for transporting food should be regularly inspected for signs of pests and for any damage to the vehicle’s integrity. Pests can not only contaminate food but also spread diseases. Lack of vehicle integrity may result in potential foreign material contamination.

- Ensuring that vehicles are well-sealed and maintained to prevent pest entry.

- Implementing integrated pest management (IPM) practices to proactively address potential infestations.

- Educate all personnel involved in storage and distribution about the importance of vehicle cleanliness and maintaining pest-free environments.

- When planning transportation routes, it is important to consider food miles to minimize environmental impact and ensure food quality. Reducing food miles by optimizing routes and choosing suitable transportation methods helps maintain freshness and supports sustainability.

- Regulatory Compliance:

Regulatory compliance in the context of food safety during storage and transportation is a multifaceted issue that requires a thorough understanding and strict adherence to both local and international standards.

This includes familiarization with various food safety regulations, such as:

- Hazard Analysis Critical Control Point (HACCP) system,

- Food Safety Modernization Act (FSMA) in the United States,

- European Union’s General Food Law.

Each of these frameworks outlines specific requirements for handling, storing, and transporting food products, aimed at minimizing the risk of contamination and ensuring the highest standards of food safety.

Compliance is not just a matter of legal requirement; it also instills trust and confidence among consumers. Businesses that demonstrate a commitment to regulatory compliance are often viewed as more reliable and responsible, which can be a significant factor in consumer decision-making. Moreover, non-compliance can lead to severe consequences, including legal penalties, product recalls, and damage to a company’s reputation.

To maintain regulatory compliance, organizations involved in food storage and transportation should take proactive measures. This includes conducting regular audits and reviews of their processes to ensure they align with current regulations. Staying abreast of any changes or updates in food safety laws is also crucial, as these regulations can evolve in response to new health research or food safety incidents.

Furthermore, investing in staff training and development is vital. Employees at all levels, from management to frontline workers, should be educated about the importance of food safety regulations and trained in best practices for compliance. This includes understanding the critical control points in their operations, proper documentation procedures, and how to respond to food safety incidents.

Through diligent adherence to regulatory standards and a proactive approach to compliance, organizations can significantly contribute to the overall safety and quality of the food supply chain, thereby protecting consumers and enhancing the integrity of the food industry.

What Digital Tools Can You Use for Food Transport and Storage?

Digital systems help food businesses monitor conditions, verify compliance, and respond quickly to risks during storage and transit. You can use these tools instead of manual checks or paper logs. This way, you get continuous data and traceability across the supply chain.

- GPS Tracking and Real-Time Monitoring can help you keep constant visibility over location and temperature control.

- Digital Checklists and Logs replace paper logs with mobile apps to track food storage, vehicle cleanliness, and loading and unloading.

- Cloud-based food safety compliance software, such as FoodReady AI, enables you to manage food safety plans, assign checklists, and store compliance records in one centralized location.

FoodReady’s digital checklist tool allows you to customize checks based on your product type and destination. If you’re already using our mobile food safety app, you can integrate these checks into daily routines with reminders and team access.

Innovations and Future Trends

If you manage food storage or transportation, you know how tough it can be to keep products safe, meet regulations, and avoid costly mistakes. The good news is that technologies are making it easier to stay in control, protect your brand, and build customer confidence.

- Blockchain in food traceability: Blockchain technology is revolutionizing food traceability, providing a transparent and immutable record of the food’s journey from farm to fork.

- Smart packaging: Developments in smart packaging, including sensors that monitor food freshness and temperature fluctuations, are promising.

- AI and predictive analytics turn real-time data into actionable insights so you can prevent breakdowns, delays, or temperature abuse before they cause waste or compliance issues.

- Automation and robotics reduce manual errors and streamline repetitive tasks, such as loading, cleaning, and monitoring, to save time and improve consistency.

- IoT monitoring systems let you see what’s happening with your products 24/7, no matter where they are, giving you peace of mind and stronger control over food safety.

Strengthening Food Safety in Storage and Transportation for a Safer Future

In conclusion, as the global population grows and the demand for food increases, the need for robust food safety practices in storage and transportation becomes more critical. By implementing effective strategies and embracing innovative technologies, we can significantly reduce food waste, ensure food security, and protect public health.

Remember, food safety is everyone’s responsibility. From farm to table, each step in the food supply chain plays a crucial role in maintaining the quality and safety of our food.

Ready to strengthen your food hygiene program?

Customize the digital solution to

your exact business operations

FAQs

Effective strategies include using GPS-enabled temperature monitoring devices for real-time tracking, investing in high-quality refrigerated vehicles, training drivers on the importance of temperature control, and implementing strict protocols for loading and unloading perishable goods to minimize exposure to non-optimal temperatures.

Smart packaging plays a critical role in food safety by monitoring the condition of food products in real-time, including temperature, humidity, and freshness. Businesses can adopt this technology by collaborating with packaging innovation companies to explore suitable smart packaging solutions for their products and integrating these technologies into their packaging processes to enhance product safety and quality.

To minimize risks, businesses should conduct due diligence on 3PL providers by reviewing their food safety certifications, audit results, and compliance records. Establishing clear contracts that specify food safety requirements and conducting joint training sessions on specific safety protocols can also help. Regularly reviewing performance and conducting surprise inspections can ensure ongoing compliance.

Digital tools, such as real-time monitoring systems, mobile checklists, and data loggers, make it easier to detect issues early, prevent contamination, and ensure regulatory compliance.

Some of the most frequent slip-ups include failing to calibrate temperature monitors, overlooking cleaning schedules for cargo areas, mixing raw and ready-to-eat items in shared space, and relying on paper records that can get lost or damaged. A well-structured transportation system identifies and prevents these issues before they escalate.

FoodReady’s software simplifies compliance by helping you build transport SOPs, assign food safety checklists, track conditions in real time, and centralize audits to make transporting food safely easier and more efficient.

Act quickly — record what happened, separate the affected food, identify the cause (such as a broken fridge or a delay), resolve the issue, and document everything. This process is part of what’s called “corrective and preventive action.” You can easily handle it with CAPA software.

When food is stored and transported safely, less of it spoils. That means less waste, lower costs, and a more sustainable supply chain. Good food safety practices protect both your business and your customers.

Keep food at the right temperature from start to finish. Use refrigerated trucks, monitor temperatures with sensors, and avoid delays when loading and unloading. Regular checks and audits help make sure the cold chain stays strong.