If you’re running a food manufacturing operation, kitchen or any food establishment, you probably already know that managing your food inventory isn’t just about knowing what’s in the cold room. It’s about ensuring profitability, reducing waste, maintaining food safety, and keeping your operations smooth as butter.

Dealing with daily deliveries, changing customer needs, food getting spoiled, and those puzzling moments when ingredients seem to vanish can make managing food stock feel like a constant struggle.

In this blog, we’ll explore the different types of food inventory control and the most effective methods you can use—all in a friendly, easy-to-digest way.

Why Does Food Inventory Control Matter?

Before we dive into the how, let’s quickly chat about the why.

- Profit Margins Matter: Food ingredients is one of the highest-cost areas in any food business. Poor control means money lost on overstocking, spoilage, theft, or mismanagement.

- Food Safety: Expired or improperly rotated ingredients isn’t just wasteful; it can be a safety risk.

- Customer Satisfaction: Running out of ingredients on the production line or during service? That’s something to be avoided at all costs.

- Operational Efficiency: Knowing your inventory helps you plan better, order smarter, and streamline your food establishment operations.

Types of Food Inventory Control Systems

1. Periodic Inventory Control

This is the old-school method, and it still mostly works.

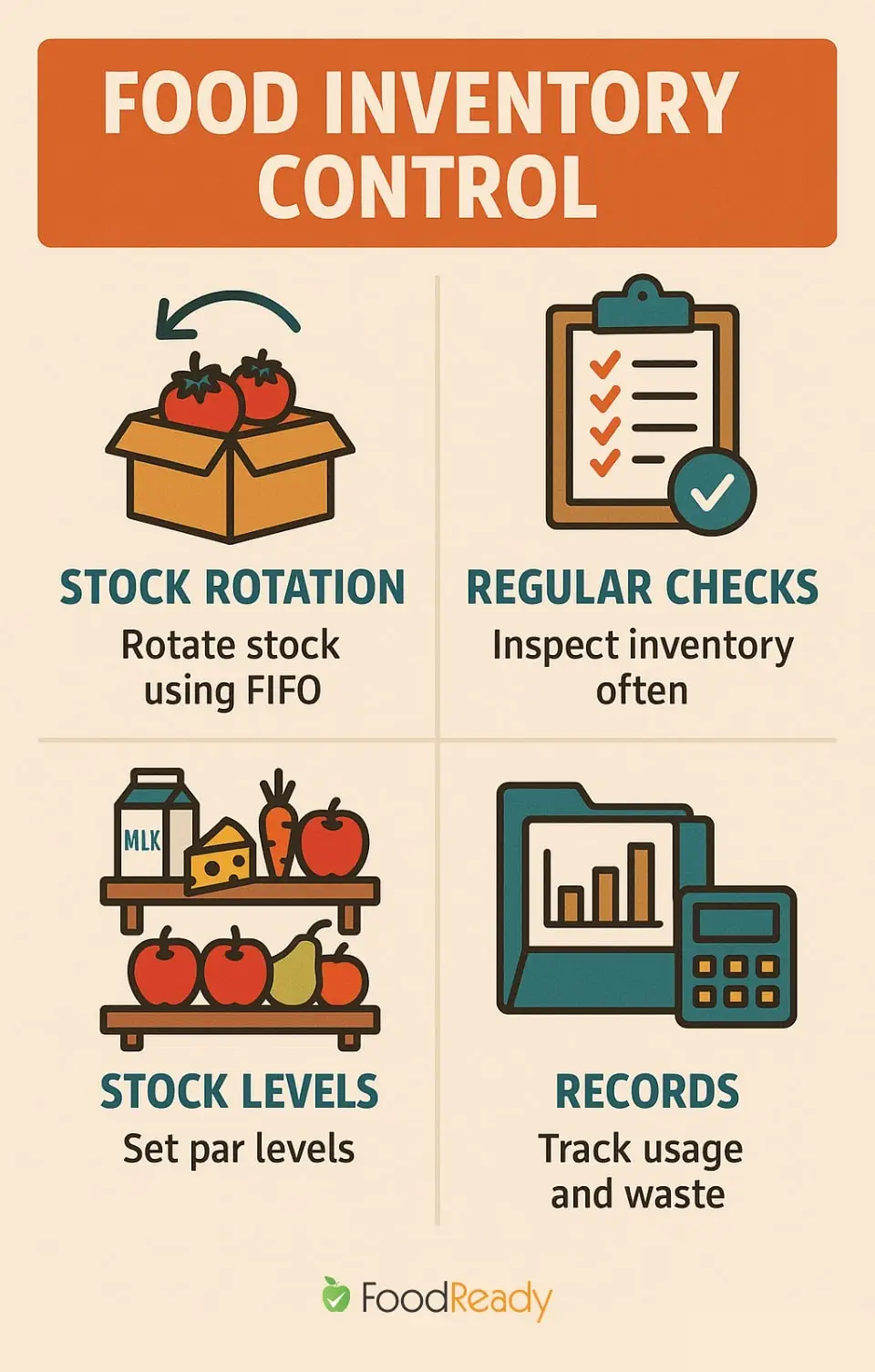

You (or your team) physically count your stock at set intervals—daily, weekly, monthly, or however often you need. You then compare the count to your records and make necessary adjustments.

Pros:

- Simple and cost-effective.

- Works for small operations with limited inventory.

Cons:

- Labor-intensive and time-consuming.

- Gaps between counts can lead to inaccuracies.

- Harder to spot shrinkage or spoilage quickly.

Tip: If you’re using periodic control, consistency is key. Schedule inventory counts at the same time and under the same conditions each period.

2. Perpetual Inventory Control

Think of this as your inventory on autopilot.

Every time you receive goods or use them, the inventory is updated in real-time (often through POS or inventory software like FoodReady). You always have a clear picture of what you have, what’s running low, and what’s going to waste.

Pros:

- Real-time accuracy.

- Helps reduce overstocking or stockouts.

- Easier to catch theft, spoilage, and usage patterns.

Cons:

- Requires reliable systems and disciplined input.

- Needs staff training and technology investment.

Pro Tip: Combine perpetual control with regular spot-checking (cycle counts) to ensure your numbers match the real-world stock.

3. Par Level System

You establish a minimum stock level (the par) for each ingredient. When stock falls below that, you reorder to bring it back up to par.

Pros:

- Simple and effective for high-turnover items.

- Prevents over-ordering and ensures you never run out.

Cons:

- Doesn’t account for fluctuating demand (like seasonal changes or promotions).

- Can still lead to overstock if not combined with sales forecasting.

Best Practice: Review your par levels regularly and adjust them based on sales data, production seasonality or menu changes.

Methods of Food Inventory Control

Now, let’s get into the most critical part—the methods you can apply to control your inventory effectively.

1. First-In, First-Out (FIFO)

This is by far the golden rule of food inventory.

FIFO means using the oldest stock first to ensure nothing expires or goes bad before you use it.

How to do it:

- When stocking shelves or coolers, place new items behind the older ones.

- Label all products with received dates.

Benefits:

- Reduces waste due to spoilage.

- Supports food safety compliance.

2. ABC Inventory Method (Always Better Control)

Also known as the Pareto Principle applied to inventory.

You categorize items into three groups:

- A items: High-value, low-quantity (e.g., expensive meats and fats).

- B items: Mid-range items in cost and volume (e.g., oils and spices).

- C items: Low-cost, high-quantity (e.g., packaging, salt, ketchup).

How it helps:

- Focus more control and monitoring on A items.

- Automate or simplify control for C items.

3. Just-In-Time (JIT) Inventory

This method aims to have stock arrive right before it’s needed.

Benefits:

- Reduces storage space and holding costs.

- Keeps stock fresh.

Risks:

- Supply chain disruptions can leave you empty-handed.

- Needs very reliable suppliers and precise forecasting.

Pro Tip: Use JIT for specialty items or perishables that have a short shelf life, but always have a Plan B.

4. Cycle Counting

Rather than doing massive, exhausting inventory counts, cycle counting is far more effective and involves counting a small portion of your ingredients and packaging stock each day or week.

For example:

- Mondays: Dairy products.

- Tuesdays: Proteins.

- Wednesdays: Dry goods.

Benefits:

- Less disruptive.

- Easier to spot discrepancies early.

- Keeps inventory data fresh.

Tech to the Rescue: Using Software for Smarter Inventory Control

Frankly speaking, manual methods can only get you so far.

Today’s inventory management software (like FoodReady’s Inventory Module) lets you:

- Track inventory in real-time.

- Generate automatic reports.

- Set par levels and get alerts when items are low.

- Predict future inventory needs based on sales trends.

Bonus: It saves you hours of admin work and helps you make smarter purchasing decisions.

What’s Best for You?

At the end of the day, there’s no one-size-fits-all method for inventory control. The best system for you depends on:

- The size of your business.

- Your food production or menu complexity.

- The volume and type of ingredients and packaging that you handle.

- Your tech comfort level and what is most user friendly for you and your staff.

Pro Tip:

Most successful operations combine several methods. For example, using FIFO for food rotation, par levels for daily ordering, and perpetual inventory software for tracking big-picture stock.

Remember, good inventory control isn’t just about spreadsheets. It’s about creating a food establishment that runs efficiently, profitably, and sustainably.

How FoodReady Simplifies and Supercharges Food Inventory Control

Frankly speaking, most operators don’t have time for complicated spreadsheets, endless manual counts, or tech that requires expert-level usage.

That’s where FoodReady comes in. Here’s how we make food inventory control feel like less of a chore, and more like a food establishment’s secret weapon.

1. Easy-to-Use Digital Inventory System

FoodReady’s mobile-friendly platform lets your team count inventory directly from their phones or tablets. Walk around the kitchen, fridge, or bar, and log items in real-time. No more scribbled notes or missed counts.

2. Real-Time Inventory Tracking (Perpetual System)

Our system updates inventory levels the moment items are used, sold, or received. It syncs with your POS system, purchase orders, and recipe database.

Bonus: You’ll always know what’s on hand, and the system will alert you when stock runs low.

3. Recipe & Ingredient Cost Tracking

FoodReady ties your recipes directly to inventory, giving you real-time insight into:

- Cost per serving.

- Ingredient usage.

- Potential margin leaks.

Imagine being able to spot a menu item that’s dragging down your profits with just a few clicks.

4. Waste & Shrinkage Tracking

Our platform allows you to log waste events easily—overcooked steaks, spoiled produce, staff meals. This data empowers you to spot patterns and make smarter purchasing or prep decisions.

5. Smart Par Level Management

Set custom par levels per item, per location. FoodReady tracks usage trends and helps you adjust par levels automatically based on data, not guesswork.

6. Inventory Turnover Reports

Remember that formula from earlier? FoodReady runs these reports for you, providing clear, actionable dashboards. You’ll know exactly which ingredients are flying off the shelves and which are gathering dust.

7. Compliance & Safety Tools Built-In

FoodReady keeps an eye on expiration dates, lot codes, and food safety documentation so you will never get caught off guard during an inspection or third party audit.

Simplify Inventory, Maximize Profit

Stop drowning in spreadsheets and sticky notes. FoodReady gives you real-time tracking, smart alerts, and cost control – all in one easy-to-use system.

How Did One Restaurant Cut Waste by 30%?

The Situation:

A popular mid-sized farm-to-table restaurant in Chicago struggled with over-ordering produce and running out of proteins on busy weekends.

The Fix:

They implemented FoodReady’s inventory control system, digitized their counts, and used the par level tools to adjust orders in real time.

The Result:

- Food waste dropped by 30%.

- No more running out of stock during weekends when supply isn’t readily available.

- Profit margins improved by 12%.

The Bottom Line.

Food inventory control doesn’t have to be overwhelming or time-consuming. By understanding the types, using proven methods, and leveraging digital software like FoodReady, you can:

- Largely reduce waste.

- Significantly improve your profits.

- Make smarter ordering decisions and procurement.

- Keep your food establishment running like a well-oiled machine.

And the best part? You can focus more on what you love – creating fabulous food products and dishes with much less headache of stock counts.

FAQ’s

For best results:

– Do weekly cycle counts by product type (e.g., dairy, proteins, dry goods).

– Conduct a full inventory audit monthly or quarterly.

– Perform daily spot checks on high-value or fast-moving items.

This layered approach ensures accuracy while minimizing operational disruption.

Some key red flags include:

– Running out of ingredients or overordering

– Frequent spoilage or waste

– Mismatches between recorded and actual stock

– Unexplained food cost spikes

– Constant last-minute supplier orders

If you’re seeing these, it’s time to reassess your process or adopt better tools.

Yes! Digital inventory tools aren’t just for big operations. Even small food businesses benefit from:

– Real-time tracking

– Reduced waste

– Smarter ordering

– Cost control

Platforms like FoodReady are designed to be affordable, mobile-friendly, and easy to scale.

Inventory control ensures:

– FIFO is followed to reduce expired stock

– Lot numbers and expiration dates are tracked

– Stock movements are logged in real time

This makes passing health inspections and third-party audits much easier and safer.

– Definitely. FoodReady links your:

– Recipes with ingredient inventory

– Sales data with cost per plate

– Usage trends with waste tracking

This gives you actionable insights to optimize menu pricing, reduce margin loss, and increase profitability.