Best Food Traceability Software

Food traceability is a crucial element in ensuring food safety and operational efficiency. Food traceability software can help you comply with FDA FSMA, SQF, BRC, and GFSI and mitigate recall risks. Feel lost about what solution to choose? Here are some food traceability platforms to help you meet your food manufacturing safety goals.

What Is Food Traceability Software for Manufacturing?

Traceability software for food manufacturing is a digital solution that helps build an efficient food traceability system and improves transparency in the food supply chain.

Using a food traceability solution, companies will promptly respond to food safety issues and maintain regulatory standards, including FSMA compliance.

How Does Food Traceability Software Work?

Food traceability software helps manufacturers track and trace the materials and ingredients in their food.

The software helps you spot supply chain issues and isolate the problem’s source, such as a contaminant.

This way, you prevent further problem development. Moreover, you create a document trail to ensure food safety, compliance, and quality.

Why Is Food Traceability So Important?

You should be aware that food traceability and recall management are some of the most critical aspects of food safety. Suppose one of the ingredients of a food product ends up being mislabeled or contaminated with pathogenic bacteria, chemicals, or physical hazards.

In that case, it’s crucial to make the buyer and end consumer aware of the recall and remove possibly dangerous food from the shelves and consumers’ mouths.

Our Criteria for Evaluating the Software Solutions

After reviewing different food traceability solutions, our expert team focused on features that drive safety, compliance, and operational efficiency.

Here are the key criteria we considered to identify the best solutions for your business:

- Key Features: Core capabilities for food traceability, such as lot tracking, recall management, data integration, and real-time monitoring.

- Platform Support: You need multi-platform support to manage traceability tasks from any device.

- Compliance & Regulatory Support: Ability to meet industry standards like FDA, FSMA, HACCP, and GFSI. Regulatory compliance is crucial to align with food safety laws and maintain consumer trust.

- Support: Comprehensive support ensures users can resolve issues promptly and fully use the software.

- Integration: Integrating with other systems (e.g., ERP, inventory, and accounting) facilitates data consistency, enhancing operational efficiency.

What Are Some of the Best Food Traceability Software Solutions?

When it comes to food manufacturing traceability software, there are a lot of options out there.

Here’s an overview of 10 food manufacturing traceability software that can help you ensure the safety and quality of your products.

Best All-in-One food traceability software for all business sizes.

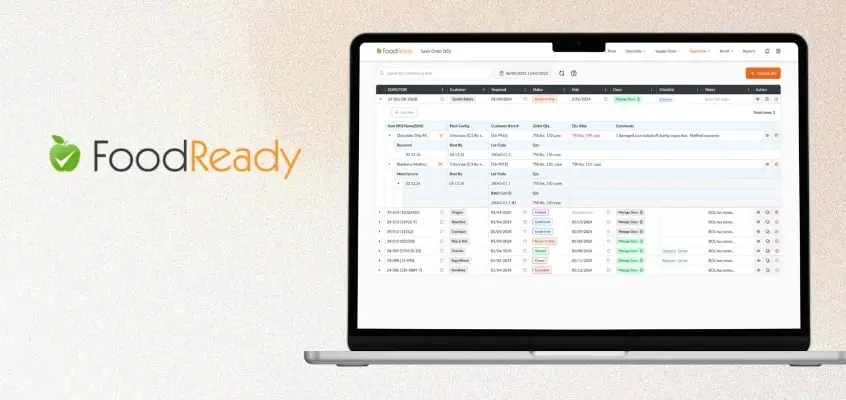

1. FoodReady AI

Pricing: Contact FoodReady AI for more information

Platforms supported: Web, iOS, and Android

Why use FoodReady AI?

FoodReady food traceability software is an excellent food safety software solution for managing your lot traceability with shipping and receiving logs. These logs are also associated with sales and purchase orders to track the inventory coming in from suppliers and going out to customers.

Develop recall plans and practice mock recalls, which can be triggered by product complaint tracking. The recall system is associated with lot numbers stored in the inventory database.

FoodReady AI Food Traceability Software Features:

- Recall Plan & Mock Recall Management – Create, test, and refine recall plans and conduct mock recalls to reduce response time and risks during recalls.

- Product Complaint Tracking – Capture customer complaints for trend analysis and corrective actions.

- Receiving & Shipping Lot Traceability and Sales Order and Purchase Order Tracking – You can link each shipment to a lot and its related orders to ensure traceability and quick identification in case of a product issue.

- Receiving GS1 Barcode Scanning – FoodReady enables GS1 barcodes to log product data automatically at receiving points.

- Inventory Management With Traceability – Ensure inventory accuracy by monitoring stock levels and lot history.

- Batch Management With Traceability – Track ingredients and materials through production batches to support traceability and food safety standards.

- Traceability Data Management – Benefit from centralized and structured traceability data.

- Supply Chain Management – Get comprehensive control and visibility over supplier performance, logistics, and product flow.

- Analytics and Reporting – Get real-time actionable insights from traceability and quality data, enabling data-driven decisions and continuous improvement.

- Regulatory Compliance – The software supports compliance with the FDA, FSMA, USDA, and global food safety standards.

- Secure Online Platform – Businesses can work safely with cloud-based secure access.

- Real-time Monitoring – Benefit from real-time tracking, improving response time to deviations or bottlenecks.

- Audit Preparation Tools and Services – Organize documentation, procedures, and historical data to ensure audit readiness and reduce stress during regulatory inspections.

How Can Our Software Help Your Food Manufacturing Business?

FoodReady food traceability platform for manufacturing is a universal tool that will help you build and manage your food traceability program with the help of a digital platform and expert FSMA 204 consultants.

We will help you comply with the FSMA 204 rule. Our professionals will assist you with creating and implementing your food traceability program.

Our software builds a transparent, efficient food traceability system, helping you manage mock recalls, inventory, and real-time monitoring. With automated reports, you can keep your supply chain transparent and compliant.

Moreover, our partnership with GS1 US brings our customers even more benefits, such as verifiable product data and easier supply chain management in compliance with regulations.

We will help you minimize costly recalls, improve your brand reputation, and grow your profitability—all with one solution and without extra paperwork and platforms. Visit our website to learn even more about our functionality and services!

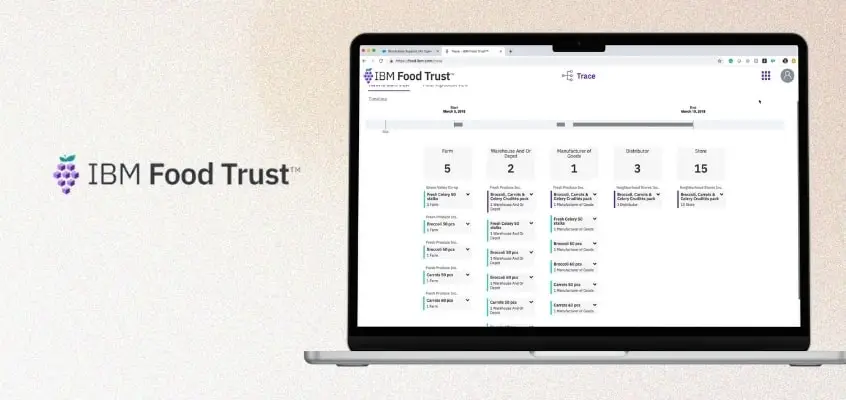

2. IBM Food Trust

Pricing: Contact IBM Food Trust for more information

Platforms supported: Web

Why use IBM Food Trust?

IBM Food Trust provides end-to-end traceability throughout the supply chain, allowing you to track products easily using identifiers like Product ID, Lot Number, or Purchase Order Number. To ensure security, data owners can control access to their data by selecting specific policies.

IBM Food Trust Features:

- Automation of Traceability Data Exchange

- End-to-end visibility and Transparency for the Supply Chain

- Validate Quality Provenance with Food Trust Network

- Streamlined Recall Management Solution

- Establish a Secure, Distributed Ledger Technology Platform

3. SAP

Pricing: Contact SAP for more information

Platforms supported: Web

Why use SAP?

SAP Business Network Material Traceability empowers food producers with comprehensive traceability across multi-tier supply chains. Tracking products from farm to shelf enables precise, efficient recalls, sustainability insights, and compliance with industry standards.

Real-time alerts, integration with SAP, and data-sharing capabilities foster transparency, reduce waste, and enhance consumer trust in food safety.

SAP Features:

- Product Tracking Across the Entire Supply Chain

- Advanced Lot Tracking

- Expiration Date Tracking

- Compliant Recall Capabilities

- Effective Analysis and Reporting

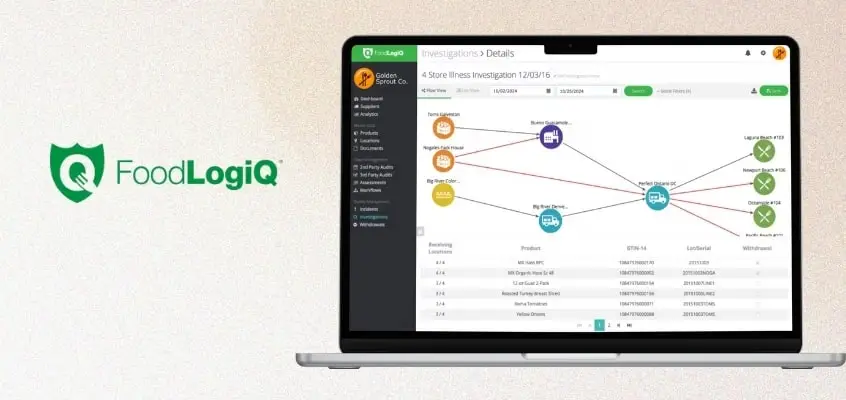

4. FoodLogiQ Connect

Pricing: Contact FoodLogiQ for more information

Platforms supported: Web, iOS, and Android

Why use FoodLogiQ Connect?

FoodLogiQ Traceability by Trustwell empowers food companies to trace products from farm to fork, ensuring FSMA 204 compliance. The software captures critical tracking event (CTE) data, enabling lot-level, GS1-aligned traceability.

Real-time alerts streamline recalls, and mobile-accessible reporting enhances audit readiness. FoodLogiQ supports grocers, manufacturers, and distributors in building supply chain transparency and consumer trust.

FoodLogiQ Connect Features:

- Automated Traceability for Raw Materials

- Real-Time Product Visibility Across the Entire Supply Chain

- Integrated Recall Management System

- Risk Analysis Tool to Identify Potential Issues Before They Occur

- Streamlined Regulatory Compliance

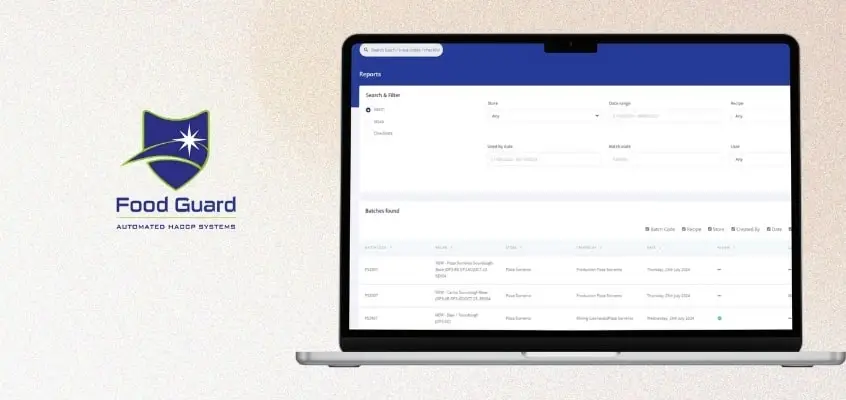

5. Food Guard

Pricing: Contact Food Guard for more information

Platforms supported: Web, Android

Why use Food Guard?

Food Guard helps manufacturers track products across the supply chain, ensuring food safety, quality, regulatory compliance, transparency, and operational efficiency.

The software enables efficient batch tracking, rapid recall management, and real-time data analytics, helping food businesses minimize risks and build consumer trust.

Food Guard Features:

- Streamlined Operations

- Real-Time Tracking

- Recall Management

- End-to-End Visibility

- Data Analytics and Insights

- Batch Tracking

6. FoodChain ID Traceability

Pricing: Contact FoodChain ID for more information

Platforms supported: Web

Why use FoodChain ID Traceability?

inSYTE™ by FoodChain ID helps retailers, suppliers, growers, finished food manufacturers, and others create and maintain a traceable global supply network.

Their cloud-based platform enables farm-to-fork and seed-to-shelf tracing, ensuring regulatory compliance on product traceability and supply chain monitoring.

FoodChain ID Traceability Features:

- End-to-End Traceability Solution

- Lot Tracking Capabilities

- Automated Data Exchange with Multiple Stakeholders

- Quality Assurance Tools and Reports

- Batch Management and Recall System

7. Sphera (Formerly SupplyShift)

Pricing: Contact Sphera for more information

Platforms supported: Web

Why use Sphera?

Sphera brings transparency and resilience to supply chain management. Its traceability tools help businesses capture Scope 3 emissions, monitor risks, and score suppliers on sustainability metrics.

For companies prioritizing ESG alignment, Sphera offers a reliable solution to meet global compliance and strengthen brand trust through sustainable practices.

Sphera Features:

- Track Products in Real Time

- Automatically Exchange Data With Partners

- Manage Recalls and Traceability Across the Supply Chain

- Track Material Sourcing and Provenance of Ingredients

- Monitor Quality Assurance Throughout the Entire Process

8. TraceGains

Pricing: Contact TraceGains for more information

Platforms supported: Web

Why use TraceGains?

TraceGains, now integrated with Veralto, is invaluable for FSMA compliance and ingredient traceability in food manufacturing.

It helps monitor Critical Tracking Events (CTEs) and supplier data, creating a connected digital system that simplifies compliance and safety across the supply chain.

TraceGains Features:

- Real-Time Tracking Capabilities

- Lot Tracking of Products

- Automated Data Exchange with Business Partners

- Integrated Recall and Compliance Management

- Quality Assurance Tools and Reports

9. Infor Supply Chain Management

Pricing: Contact Infor Supply Chain Management for more information

Platforms supported: Web

Why use Infor Supply Chain Management?

Infor CloudSuite Food & Beverage is built to meet the complex traceability and compliance needs of today’s food companies.

With capabilities to track ingredients and monitor every stage of the supply chain, this cloud solution enhances product safety, improves yield, and shortens Time to Market. Real-time data visibility and AI tools make it easier for F&B brands to respond swiftly to quality concerns while optimizing processes for consistent results.

Infor Supply Chain Management Features:

- Real-Time Inventory Tracking

- Automated Data Exchange with Partners

- Lot and Batch Traceability to Monitor Quality Assurance

- Regulatory Compliance Monitoring

- Streamlined Recall Management Solution

10. Farmsoft

Pricing: Contact Farmsoft for more information

Platforms supported: Web

Why use Farmsoft?

FarmSoft’s traceability tools are well-suited for agricultural operations focused on compliance.

With QR codes for tracking products from farm to table and support for USDA and HACCP standards, the platform offers real-time visibility and simplified inventory management. It could be valuable for those seeking greater efficiency and customer trust.

Farmsoft Features:

- Real-Time Traceability

- Automated Data Collection & Record Keeping

- Recall Management & Notification

- Lot & Batch Code Scanning

- Auditing, Reporting & Analysis Tools

- QR Code and RFID Traceability

- Blockchain Traceability Option

- Inventory Management with FIFO & Barcode/RFID

These 10 food traceability solutions are designed to help food companies ensure product safety, comply with FDA regulations, and help you pass a 3rd-party audit like SQF, BRC, and FSSC 2200.

Here is a comparison table highlighting some key aspects of each traceability solution.

Software | Deployment | Trial / Demo | Customer Support | Pricing Info |

FoodReady | Cloud, Mobile | Free 14-day trial, Demo | Dedicated Support, Phone, Email | Contact for pricing |

IBM Food Trust | Web | Demo | Chat, Ticket | Starting from $2000/month |

SAP | Cloud | Demo | Dedicated Support, Contact | Contact for pricing |

FoodLogiQ Connect | Cloud, Mobile | Demo | Phone, Email, Ticket, Knowledge Base | Contact for pricing |

Food Guard | Cloud | Free trial, Demo | Phone, Email | Contact for pricing |

FoodChain ID Traceability | Cloud | No | Phone, Email, Ticket | Contact for pricing |

SupplyShift (Sphera) | Cloud | Demo | Chat, Phone, Email | Contact for pricing |

TraceGains | Cloud | Demo | Ticket | Contact for pricing |

Infor Supply Chain Management | Cloud, On-premise | Demo | Chat | Contact for pricing |

FarmSoft | Cloud | Demo | Dedicated Support | Starts at $84/week |

How To Implement Traceability Software for Food Manufacturing?

First, your team must thoroughly assess your current operation and determine where tech can add the most value. It could be tracking raw materials, monitoring finished goods, or responding to potential recalls.

Involve cross-functional teams early on to ensure every department understands how traceability impacts their workflow. The teams’ contributions would smooth out the integration phase, especially when aligning new software with existing inventory or ERP systems.

Employee training is key to successful implementation. Start by identifying “traceability champions” from each department—these are team members who receive advanced training and can support others. Create hands-on sessions focusing on:

- Logging product information

- Tracking shipments

- Real-time data

- Purchase management

What about follow-up questions, easy-to-follow guides, or cheat sheets?

Well, as long as it reinforces learning, everything is acceptable.

Also, as your traceability system improves, consider ongoing, small refresher sessions every quarter to keep skills sharp and introduce new features.

Keep in mind that real-time data is only as reliable as the information entered, so emphasize the importance of precise entries. For that reason, your company needs to establish best practices by setting clear guidelines around data entry and reporting accuracy.

With a well-planned setup and committed training program, your team will be well-prepared to leverage traceability software for improved business operations.

9 Key Food Traceability Software Benefits for Manufacturers

Food manufacturers want to know more about the solution’s benefits when choosing food traceability software.

However, you can be 100% sure food traceability software has various advantages (beyond improved traceability, obviously) that include:

1. Ensure Regulatory Compliance With Food Traceability Software

The FDA FSMA 204 compliance date is approaching, and food traceability software can help you meet the established traceability recordkeeping requirements.

The solution can automatically generate reports and other documents and store them in the cloud, making them easily accessible and manageable.

Traceability software’s features help you prepare for food safety audits such as SQF, BRC, etc., stay compliant with regulations, and reduce non-compliance risks.

2. Food Traceability Software Enhances Quality Control and Food Safety

Food safety and quality are the fundamental aspects of food manufacturing, and businesses must establish a proactive approach to handling food safety risks and ensuring high product quality.

A great benefit of traceability software for manufacturing is that it helps prevent low-quality and hazardous foods from reaching the consumer.

The solution lets you track, spot, and quickly eliminate contaminated products, avoiding foodborne diseases.

3. Become Recall-Ready With Food Traceability Software

Recalls are scary and undesirable because they are expensive and undermine your reputation. However, food traceability software helps avoid them or make them more manageable.

The solution gives you the visibility you need to react to recalls swiftly.

Indeed, it will help you catch the issue in the supply chain, withdraw the affected batch, and prevent further contamination.

To learn more, read our detailed guide on managing FDA recalls.

4. Food Traceability Software Saves Your Time

The software automates the processes, helping you do regular and repetitive tasks faster, create traceability logs in seconds, generate documents, and access the system in no time, saving you precious time.

As a result, food traceability software helps you and the team focus on other essential tasks without scattering their attention on routine tasks.

5. Achieve Complete Transparency in the Food Supply Chain

The software tracks the movement of products in the supply chain, increasing awareness of what is happening.

It also integrates with other systems and technologies, such as food ERP and IoT devices, to give you a more holistic view of the situation in food production.

6. Revolutionize Inventory Management With a Traceability Solution

Food traceability software enables real-time ingredient and product tracking, helping you control stock levels and expiration dates.

You will be able to prevent overstock, reduce waste, and optimize the usage of perishable products.

With the inventory management feature, the software will help you save money, minimize spoilage, and improve efficiency and resource utilization,

7. The Software Enables Supply Chain Optimization

Food traceability software helps achieve visibility, identify bottlenecks, and optimize processes overall.

Moreover, the software streamlines collaboration with suppliers and shortens the response time to disruption and market demands.

An automated solution like food traceability software helps you digitize and streamline operations, establishing better collaboration and work processes in the supply chain.

8. Food Traceability Software Helps Boost Operational Efficiency

You can significantly automate and optimize the production processes with food traceability software.

The solution eliminates manual recordkeeping, improves data exchange and decision-making, and reduces labor and administrative costs.

Properly implemented, food traceability software will significantly streamline operations, improving efficiency.

9. Traceability Software For Brand Reputation and Business Growth

Food traceability software helps you create a quality product to win customers’ trust and strengthen your brand name.

In addition, you’ll be able to enter new markets where traceability is a must and will overtake your competitors in your current market.

The more serious your approach to food safety, company efficiency, and compliance regulations is, the more successful and reputable you are.

3 Common Challenges in Food Traceability Software Implementation

While food traceability platforms offer valuable benefits, companies must navigate several challenges to implement them successfully.

1. Costs

Cost is often a primary concern, especially for small to mid-sized businesses. Some solutions are priced at tens of thousands of dollars and require additional customization fees.

2. Complex Implementation Process

Beyond cost, implementing a new solution demands time and effort, as workflows need adapting and staff training becomes essential.

3. Security

Data security is another critical factor; software handling sensitive information must have robust encryption and access controls to prevent breaches. Addressing these hurdles from the start can help companies achieve a smoother integration and avoid costly setbacks.

Why Is Food Traceability Software Essential for Meeting Regulatory Standards?

Meeting regulatory standards, such as SQF certification, requires rigorous food traceability.

Consider companies like True Essence Foods, which prioritize clean, natural ingredients and sustainable methods. For them, traceability solutions aren’t just helpful—they’re essential for maintaining transparency and meeting regulatory and environmental goals.

Using FoodReady’s software, True Essence Foods established real-time tracking for ingredient sources and product movement, which is critical for SQF compliance. This solution made it simple to document batch data accurately and easily access records during audit processes.

“The traceability FoodReady provided with recording, tracking, and the ability to search historical data was excellent to aid in our SQF goal.”

Built-in tools like task managers and checklists streamlined team operations and cut costs by reducing the need for additional hires as they scaled. For companies with high standards, robust traceability software enhances both compliance and consumer trust.

Conclusion

No matter which food manufacturing traceability software system you choose, it’s essential to ensure that your products remain safe and compliant with all regulations. The right food traceability platform can help you maintain the safety and quality of your products while streamlining processes like recalls, lot tracking, data sharing, and more.

One of these food traceability solutions, like FoodReady food manufacturing traceability software, can help you with food traceability and recall management, ensuring that your customers receive safe, high-quality products every time. With the right software tools, you can be confident in keeping your business running safely and smoothly.

Gerry Galloway

Looking for Food Traceability Software?

Try out FoodReady Software

Frequently Asked Questions:

Is food traceability software necessary for FSMA?

A robust food traceability platform is essential for meeting the stringent requirements of the US Food and Drug Administration (FDA)’s Food Safety Modernization Act (FSMA).

What does a food traceability system do?

It allows you to track each ingredient at every supply chain step and quickly and easily detect issues.

Do you need to have a recall plan in place before selling to the consumer?

The FDA requires that an effective food recall plan be in place before a product reaches consumers. This means that manufacturers must have detailed records of their suppliers, customers, and all transactions between them.

How does traceability software help with FSMA requirements?

Having reliable traceability software provides the visibility needed to comply with FSMA requirements and helps ensure consumer safety by allowing for faster recalls when issues arise.

What technologies are used in food traceability?

Food handlers can use food traceability technologies like IoT devices, blockchain technology, or radio-frequency identification (RFID).

What is the FDA's definition of food traceability?

The Food and Drug Administration defines traceability as tracking & tracing the movement of food products throughout the supply chain, backward and forward.

How does a food traceability solution help manage allergens and cross-contamination risks?

The software creates a robust ingredient traceability system that will help track allergens and allergen-related data. Additionally, it enables better visibility, helping manufacturers catch and isolate allergens and contaminated products on time.

What is the difference between cloud-based and on-premise food traceability platforms?

Cloud-based food traceability software solutions are more flexible and scalable and perfectly fit multi-location or remote businesses searching for agility. On-premise food traceability solutions are hosted locally and can provide more security.

How does food traceability software reduce food fraud risks?

Food traceability solutions help minimize food fraud risks by enabling real-time product tracking, detailed documentation, and enhanced transparency.

With the food traceability software, you can detect mislabeling, counterfeiting, and other fraudulent activities.

How to choose the best food traceability software?

You should look for features like batch management, lot tracking, document control, analytics and reporting, barcode scanning, etc. Apart from that, review the case studies of the software provider, check reviews, and compare prices.

How does food traceability software handle data security?

Modern software solutions implement advanced encryption, user authentication, and secure access controls. Moreover, the providers often adhere to cybersecurity compliance frameworks.

What food industry segments can benefit the most from food traceability software?

Any branch of the food supply chain can find the software helpful and benefit from it.

Speak with our

Expert Consultants

Get a Free Consultation With Our Food Safety

and Quality Experts Today!