When you first step into the food industry, you will quickly understand that food safety isn’t just about following a set of rules. Rather, it is about making it a culture where every one understands the importance of their role in delivering safe, high-quality food.

This journey leads you to understand and implement a food safety management system (FSMS), a comprehensive system that is designed to manage food safety risks and assist with regulatory standards.

What Is a Food Safety Management System?

FSMS meaning refers to a systematic approach that involves various processes and procedures to control food safety hazards throughout the food production chain. This food management system is dynamic and moves along with your business, as it’s not just about documentation or a checklist – it requires dedicated time and efficient team members to execute the thorough process.

Food Safety Management System Definition

A food safety management system definition encompasses a structured framework designed to manage, monitor, control and identify potential hazards throughout food operations. The purpose of food safety management system is to ensure food safety at every level of production, from raw materials to final consumer delivery, while maintaining regulatory compliance and protecting public health.

To mange, monitor, control and identify the potential hazards, FSMS is the core for effective food safety management.

Why FSMS Matters?

If you’re running a food business or planning to, you need to think seriously about putting a food safety management system in place.

As someone who’s worked closely with food manufacturers of all sizes, I can tell you firsthand that this is one of the most important steps you can take to protect your product, your customers, and your brand.

Implementing an FSMS isn’t about ticking boxes or making regulators happy (though it does help with that too).

What is the purpose of food safety management system? It’s about building a strong foundation that helps your operations run smoother and makes food safety second nature for your team.

What Are the Core Components of an Effective FSMS?

Let me break it down for you. One of the first and most important benefits you’ll see is easier compliance. Local, national, and international food safety regulations are only getting stricter. And rightly so.

But trying to stay on top of them manually?

That becomes a full-time job.

With a well-structured food safety management system, you can map out your food safety controls in one system, audit them regularly, and stay ahead of inspections. It makes your life easier and builds real confidence with auditors and customers.

Speaking of customers, having an FSMS in place has made it easier to build confidence in our products. By being transparent about the processes we follow and the safety protocols in place, we’ve reassured our customers that their health and safety are always our top priority. The more we focus on keeping things clear and visible, the more our customers trust us to deliver safe, high-quality food every time.

At the core of our food management system are several key components that keep everything running smoothly. The first step in our system is hazard analysis, where we identify potential risks whether biological, chemical, or physical, that could affect the food we produce. This proactive approach helps us pinpoint areas of concern before they become problems.

Hazards can be controlled or eliminated if we heavily focus on (CCPs) Critical Control Points that are the key stages in the food production process. Identifying these points is crucial for minimizing risks and ensuring safety. Once we’ve pinpointed those control points, we establish clear procedures to monitor them regularly and ensure things are always on track.

In case things don’t go as planned, our FSMS includes corrective actions. If any part of the process deviates from the established guidelines, we have a clear plan in place to correct it right away. When challenges arise this helps us maintain high standards consistently.

To keep everything in check, we perform regular verification procedures. This ensures that the food safety management system is working as intended and allows us to make adjustments if necessary. And of course, keeping track of everything through thorough documentation and record-keeping is essential. These records allow us to prove compliance and allow us to review our process continuously.

Having these components in place doesn’t just keep us compliant; it builds a system that ensures food safety at every level. As we continue to improve our FSMS, we know that we’re not just meeting standards; we’re raising the bar for what food safety should look like in our industry.

What Are the Principles of a Food Safety Management System (FSMS)?

When it comes to food safety, having the right systems in place isn’t just a regulatory checkbox; it’s about protecting your brand, your customers, and your peace of mind. That’s where the principles of a Food Safety Management System (FSMS) come in. Think of them as the backbone of any operation that takes food safety seriously.

At the heart of any effective food safety management system is Hazard Analysis and Critical Control Points (HACCP). This principle helps you identify potential risks like contamination or spoilage and put controls in place to stop them before they become a problem. But HACCP alone isn’t enough. That’s why we also rely on Prerequisite Programs (PRPs) like sanitation practices, pest control, and personal hygiene. These are your day-to-day basics that keep the environment clean and operations consistent.

Management commitment is another core principle. Without leadership backing food safety efforts, systems tend to fall apart. When top management invests in resources, training, and culture, food safety becomes part of how the whole business thinks and operates.

The principles of communication and continuous improvement is added to that. To ensure that everyone is on the same page clear communication between departments, teams and every suppliers is necessary.

What is food safety management system improvement?

That’s about learning from audits, feedback from customers, and performance reviews.

Together, these principles aren’t just guidelines. They’re how you build a reliable, proactive, and compliant food operation that customers can trust.

Real-World Food Safety Management System Example

A study in Singapore evaluated the impact of implementing food safety management systems in food catering service establishments.

There were 42 foodborne disease outbreaks and 521 food hygiene violations associated with catering service establishments from 2012 to 2018.

The research found that 18 months after FSMS implementation, there was a 78.4% decrease in the average level of foodborne disease outbreaks in these operations. This major reduction emphasizes the effectiveness of a properly implemented food safety management system in improving food safety standards.

Take Control of Your Food Safety Like the Pros

Just like Singapore’s catering businesses dramatically reduced foodborne outbreaks with their food management system, your operation can achieve similar results.

With FoodReady AI’s FSMS software, you can easily build digital HACCP plans, run internal audits, and monitor critical control points in real time.

Our FSMS software helps you:

- Stay compliant

- Prevent costly mistakes

- Build customer trust

Explore how FoodReady can simplify your food safety management system implementation today!

Make FSMS Work for You, Not Against You

Set up smart workflows, hazard tracking, and automated alerts – all in one system.

Who Is Responsible for Implementing a Food Safety Management System (FSMS)?

The short answer? Everyone involved in food handling plays a role but leadership holds the key.

Ultimately, senior management or business owners are responsible for establishing food safety objectives, allocating resources, and integrating a food safety culture into daily operations. While food safety may seem like a quality control issue, its implementation begins with them.

If you’re starting a food business, whether it’s a cloud kitchen or a manufacturing plant, you’re the one responsible for putting a food management system in place.

How to Get Started with FSMS in Your Business?

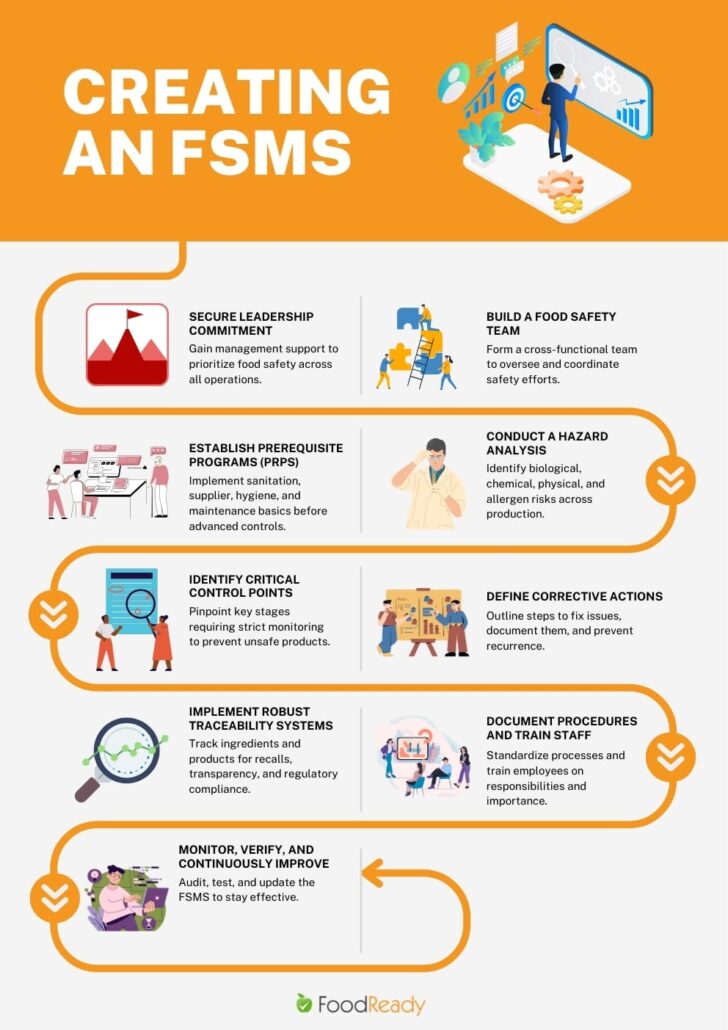

Getting your food safety management system (FSMS) up and running might feel overwhelming at first, but once you break it down into steps, it becomes more approachable and practical. Each stage builds on the previous one, creating a system that protects consumers, strengthens operations, and supports regulatory compliance.

1. Secure Leadership Commitment

The first step is one that cannot be skipped: gaining real commitment from your leadership team. Without their support, it becomes difficult to prioritize food safety across departments or allocate the right resources. When leadership actively supports the FSMS, it sends a clear message to every employee that food safety is a fundamental part of how the business operates every day.

2. Build a Food Safety Team

Once leadership buy-in is secured, the next step is to assemble a dedicated food safety team. This group should represent different areas of your operation, such as production, quality control, sanitation, and logistics. They don’t all need to be food safety experts, but together they should be capable of setting clear goals, coordinating responsibilities, and responding quickly when issues arise.

3. Establish Prerequisite Programs (PRPs)

Before diving into detailed hazard controls, organizations need a strong foundation of prerequisite programs. PRPs are the everyday practices that keep facilities clean, organized, and compliant.

These include:

- Sanitation procedures

- Supplier approval and management

- Equipment calibration and maintenance

- Personal hygiene standards

- Pest control measures

By putting these building blocks in place, you create an environment where hazards are less likely to occur, making later stages of the FSMS more effective.

4. Conduct a Hazard Analysis

With the foundation established, it’s time to review your processes. Walk through each stage of production and ask, “Where are the risks?” Hazard analysis involves identifying potential biological, chemical, or physical threats, along with allergen risks. Every step—receiving raw materials, processing, packaging, and distribution—should be evaluated for vulnerabilities.

5. Identify Critical Control Points

Once hazards have been identified, determine the critical control points (CCPs). For each CCP, set up monitoring procedures to track performance consistently. By doing so, your team can catch deviations early and take action before they escalate.

6. Define Corrective Actions

Even the best systems encounter problems. Corrective actions outline exactly what steps to take when a CCP is not under control. For example, when cooking temperatures are not achieved or allergen labeling errors occur. These procedures should clearly state how to fix the issue, document it, and implement measures to prevent recurrence.

7. Implement Robust Traceability Systems

Traceability is a vital part of a modern FSMS. It ensures you can track ingredients and finished products one step back (to your suppliers) and one step forward (to your customers). This ability is critical when responding to recalls or quality issues.

Under regulations like the FDA’s FSMA 204 rule, certain high-risk foods now require enhanced recordkeeping for traceability. This means documenting Key Data Elements (KDEs) such as:

- Lot codes

- Supplier information

- Dates of production and shipment

- Transformation events (e.g., mixing, cooking, repacking)

- Final distribution details

A strong traceability program allows you to:

- Quickly isolate affected lots in the event of contamination

- Minimize the scope and cost of recalls

- Provide transparency to regulators and customers

- Build consumer confidence by showing accountability

Traceability is about protecting your brand and responding quickly when safety is at stake.

8. Document Procedures and Train Staff

Every process, such as PRPs, hazard analysis, CCP monitoring, corrective actions, and traceability, must be documented. Clear procedures and records demonstrate compliance with regulators and auditors while ensuring consistency across shifts and facilities.

Equally important is staff training. Employees should understand not just what to do but also why it matters. When training links daily tasks to the bigger picture of protecting consumers, food safety becomes a shared responsibility across the organization.

9. Monitor, Verify, and Continuously Improve

An FSMS is not a static system. Monitoring ensures controls are working as intended every day, while verification activities like internal audits, product testing, and management reviews confirm its effectiveness.

Continuous improvement can take several forms, such as:

- Updating procedures when new hazards are identified

- Incorporating lessons learned from corrective actions

- Adapting to new regulatory requirements

- Leveraging technology for real-time monitoring and reporting

By treating your FSMS as a living system, you can stay ahead of risks, maintain compliance, and strengthen consumer trust.

FSMS Certification: What You Need to Know?

Getting certified isn’t just about getting a certificate to hang on your wall. It’s about proving to regulators, partners, and your customers that your food safety management system practices are real, tested, and effective.

Here are the most recognized FSMS certification schemes:

- ISO 22000 – A global standard integrating HACCP principles with broader management systems. Ideal for international food operations.

- SQF (Safe Quality Food) – GFSI-benchmarked and recognized by many U.S. retailers.

- BRCGS – Common in the UK and Europe, often required for export.

- FSSC 22000 – ISO-based and widely accepted in large-scale food manufacturing.

Each certification involves:

- A formal audit of your FSMS

- Evidence of compliance (HACCP plans, SOPs, monitoring)

- Staff training and documentation

Pro tip: Start with digital FSMS software like FoodReady to organize all your food safety documentation in one place. It saves time, stress, and helps you get audit-ready fast.

Make FSMS Part of Your Daily Operations

Verification is another important piece of the puzzle. Every so often, step back and ask: is this system working the way it should? Are your checks being done properly? Are the control points still relevant? Regular internal reviews or audits help you stay on track and adapt when things change, like if you switch suppliers or introduce a new product.

Finally, you’ll need a reliable way to keep records. This doesn’t mean filling binders with paper logs that never get looked at. It means setting up a system, digital FSMS software or otherwise; that lets you track procedures, checks, incidents, and improvements over time. Good documentation not only keeps you compliant but also gives you a clear picture of how your processes are performing.

Building and running a food safety management system isn’t about creating more paperwork or slowing down production, it’s about creating structure, reducing risk, and protecting everything you’ve worked hard to build. Once the system is in place and becomes part of your routine, you’ll find that it gives you more control and confidence in your operations. It doesn’t need to be perfect from day one, it just needs to start. And from there, you can build it into something strong and reliable.

Impact of FSMS Implementation in Food Businesses (General Industry Data)

| Area of Improvement | Before FSMS Implementation | After FSMS Implementation | Source/Insight |

| Food Safety Audit Scores | ~70–75% | ~90–95% | Based on internal data from FSMS providers and client reports |

| Customer Complaints | High (frequent issues) | Reduced by 40–60% | Industry benchmarks from foodservice audits |

| Order Accuracy | 80–85% | 95–98% | Observed in cloud kitchens using FSMS tools |

| Regulatory Compliance Failures | 2–3 per quarter | 0–1 per quarter | Post-audit evaluations from third-party certifiers |

| Operational Efficiency | Moderate (manual tracking) | High (automated systems) | FSMS digital platform user feedback |

Continuous Improvement

An FSMS is not a one-time setup; it’s a continuous cycle of improvement. Staying updated with audits and training as per regulatory requirements are essential to keep systems running smoothly.

Challenges in Creating and Implementing a Food Safety Management System

Rolling out a food safety management system (FSMS) is not simply about writing policies; it’s about aligning your operations with recognized standards such as ISO 22000, FSSC 22000, SQF, BRCGS, or IFS. These frameworks provide structure and credibility, but adopting them often reveals challenges that require careful navigation.

Leadership and Culture Alignment

International benchmarks like ISO 22000 emphasize leadership commitment, yet many businesses struggle to secure genuine buy-in. Management may agree to certification goals but hesitate to allocate the time, staff, and financial investment needed. Without strong cultural reinforcement from leadership, food safety risks being overshadowed by production targets.

Cross-Department Coordination

Standards recognized by the Global Food Safety Initiative (GFSI), such as SQF or BRCGS, require evidence that food safety is embedded across departments. Quality teams often carry the weight while production or logistics see food safety as a secondary concern. Breaking down silos and fostering shared responsibility is a common hurdle.

Resource and Technical Demands

Compliance with Codex HACCP principles or certification under FSSC 22000 demands resources for training, laboratory testing, and continuous monitoring. Smaller companies, in particular, may lack technical expertise or budget, making it difficult to meet the rigorous documentation and verification requirements that these schemes mandate.

Training and Workforce Engagement

Schemes like SQF and IFS expect organizations to demonstrate effective training and staff competence. However, consistent training across shifts and facilities is challenging. Employees may revert to old habits, especially under time pressure, and management must find ways to make food safety part of everyday culture.

Traceability and Recordkeeping

Modern traceability rules—particularly under FSMA 204 in the U.S.—go beyond traditional one-step forward, one-step back requirements. Entities like BRCGS and FSSC 22000 also place heavy emphasis on accurate records. Paper-based systems often fall short, making digital traceability solutions essential for compliance and for quickly isolating affected products in case of a recall.

Balancing Safety and Efficiency

Across all FSMS frameworks, a recurring challenge is balancing rigorous safety protocols with production efficiency. Whether complying with SQF audit criteria or preparing for a BRCGS inspection, companies must find ways to integrate food safety requirements into workflows without disrupting throughput. This balance is often what separates successful systems from those that fail under pressure.

Conclusion

To transform the way you handle your operations can be smooth with implementing an FSMS, its proactive approach to food safety and quality. Its a complete journey abd the rewards can be amazing in terms of customer trust, compliance and excellence on products production, all worth the effort.

If you’re considering implementing or enhancing your FSMS, I encourage you to explore resources and training programs that can provide guidance tailored to your specific needs and you always contact us for us to handle the tasks easily for your production houses.

FAQs

It’s a structured system for making sure the food you serve or sell is safe to eat, using procedures like hazard checks, documentation, and regular audits.

While not always legally required, FSMS is often essential to meet government regulations and retail partner expectations.

Hazard identification, control measures (like HACCP), monitoring, and continuous improvement.

Choose a standard (like ISO 22000), build your system, document everything, and get audited by a certification body.

Platforms like FoodReady help manage HACCP plans, automate audits, assign team responsibilities, and ensure food safety compliance.

Implementation typically takes 3-6 months for small businesses and 6-12 months for larger operations, depending on complexity, existing processes, and team readiness. The timeline includes planning, staff training, system setup, and initial monitoring phases

Costs vary widely but typically range anything from $5,000 upwards for food businesses, including training, documentation, initial audits, and FSMS software subscriptions. Long-term benefits often outweigh initial investments through reduced compliance issues and improved operational efficiency.