Imagine running your food production business by juggling multiple spreadsheets, disparate documents, and random notes. You would be way more efficient and productive with a food ERP software system.

An Enterprise Resource Planning (ERP) software solution brings all the parts of your business into one place, making the processes smoother and faster.

ERP software solutions are now one of the most essential tools for food manufacturers and food production business owners.

But what is a food ERP software solution, and how does it help companies stay competitive, compliant, and profitable?

In this blog, I’ll unpack the essentials of ERP in the food and beverage industry, explore its benefits, describe how it works, and help you find the answers to other important questions. Let’s get it started!

What Is a Food ERP Software Solution (Enterprise Resource Planning)?

ERP stands for Enterprise Resource Planning, designed to manage business operations from a single system.

ERP software for food manufacturing combines functions like procurement, production, inventory management, quality control, and distribution into one seamless interface.

This integration helps food businesses operate more efficiently and make data-driven decisions.

Think of it as your business’s central nervous system. It automates processes, eliminates siloed information, unifies departments, and provides real-time data.

The history of food ERP started in the 1960s when ERP was created as an inventory control system.

In the 1980s, it evolved from MRP (Material Requirements Planning) to MRP II (Manufacturing Resource Planning), forming the basis for modern ERP software systems.

Gartner officially introduced the term “ERP” in the 1990s. It started to cover wider functionality, connecting all departments across an organization.

The Smart AI ERP Solution for Food Businesses

Digitize operations, simplify compliance, and get audit-ready with FoodReady’s next-gen AI ERP software tailored for the food industry.

This is how we know food manufacturing ERP software today.

ERP evolved over the decades and became even more powerful with cutting-edge features like artificial intelligence and cloud computing.

Moving to the cloud made ERPs more accessible, empowering large and small businesses to stay competitive in a fast-changing digital world.

The North American ERP Market size is now estimated at USD 22.23 billion in 2025. It is also expected to reach USD 35.01 billion by 2030.

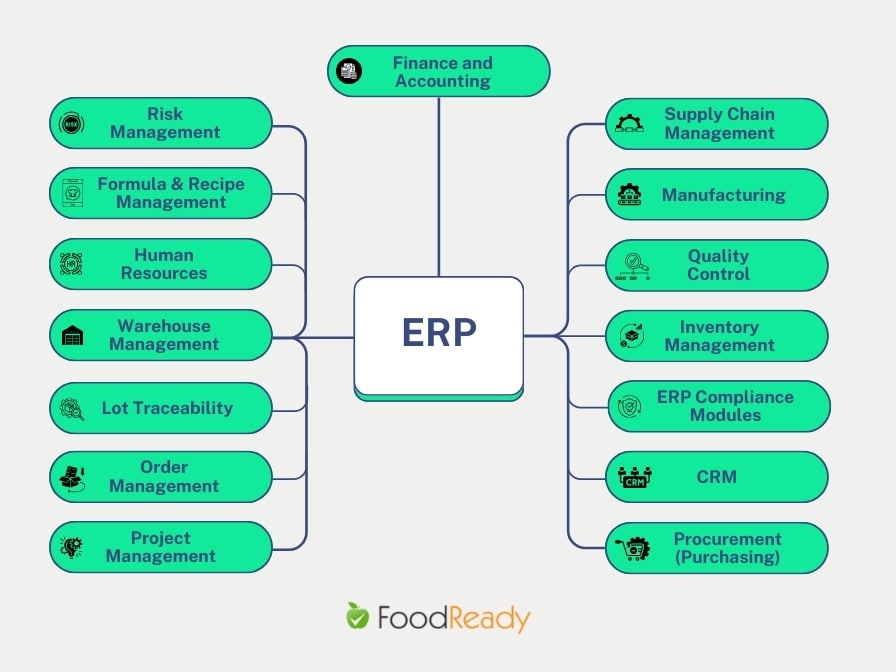

Essential ERP Software Modules for the Food Manufacturing Industry

Food ERP software is a comprehensive system consisting of multiple inventory management modules and features. Let’s look at some of them and see how they can help your business.

1. Finance and Accounting

This module manages budgeting, forecasting, accounts payable and receivable, and financial reporting.

It’s the heart of food ERP software, ensuring clean financial records, supporting audit readiness, and helping the company understand its economic situation.

2. Supply Chain Management

It monitors goods from raw materials to delivery, and its capabilities include procurement, demand forecasting, supplier management, shipping logistics, and warehouse coordination.

3. Manufacturing

The manufacturing module provides real-time production control, plans and manages production, and optimizes factory operations.

But how about MES software? Doesn’t it cover manufacturing? Yeah, but there are differences. Read our blog about ERP vs. MES and find out!

4. Quality Control

Being another pillar of food and beverage ERP, it automates quality checks, maintains food safety plans, handles deviations, minimizes recalls, and ensures compliance with industry standards.

5. ERP Compliance Modules

ERP compliance modules help food and beverage manufacturers meet FSMA, GFSI, SQF, BRC, and other regulatory requirements.

You will efficiently handle digital audit trails, SOPs, document control, and real-time compliance monitoring.

6. Inventory Management

The inventory module tracks what’s in stock, on order, and what needs to be replenished. It also helps reduce waste, prevents stockouts, and improves food traceability.

7. Customer Relationship Management (CRM)

CRM module helps store customer and prospect data, helping sales and service teams stay on top of relationships.

It allows you to contact and track leads, manage sales pipelines, handle customer support, and use marketing campaign tools.

8. Procurement (Purchasing)

The procurement module manages the entire purchasing lifecycle, from supplier selection to goods receipt.

It helps automate, control, and analyze quote requests, prepare and send purchase orders, and fosters more strategic sourcing decisions.

9. Project Management

The project management module helps plan, track, and complete projects on time and within budget.

You can assign tasks, track time, manage budgets, and analyze progress dashboards to increase productivity, control costs, and improve accuracy.

10. Order Management

This module organizes and connects everything in one place, including orders placed online, through a sales team, or via distributors.

It helps track, process, and fulfill sales orders from start to finish, ensuring smooth operations.

11. Warehouse Management

The module efficiently optimizes warehouse operations by leading employees through the processes.

It centralizes sales order data and integrates with other food ERP modules for accurate and efficient order handling.

12. Human Resources

HR module handles employee records, payroll, hiring, and performance.

You can use it to track payroll and benefits, handle attendance and leave management, benefit from recruitment tools, and track employee performance.

13. Risk Management

Food and beverage ERP software combined with AI helps companies identify, assess, monitor, and respond to potential risks related to finance, operations, regulatory compliance, etc.

You will centralize risk-related data and processes, which allows you to create a proactive, company-wide risk management strategy.

14. Formula and Recipe Management

Food and beverage ERP can help you standardize and optimize recipe management.

You can store and manage recipe and formula versions and adjust ingredients based on batch size, yield, or nutritional requirements.

15. Lot Traceability

ERP helps track product journeys from farm to table, ensuring full forward and backward traceability.

It enables efficient batch and lot tracking for recall and audit readiness and can integrate with inventory, production, and quality modules for end-to-end tracking.

How Does ERP Work in the Food and Beverage Industry?

We already know that ERP consists of modules, which all share the same database and are connected by it.

It allows them to synchronize and access real-time data that provides a complete overview of departments’ performance.

Suppose you’ve received an order for 5,000 loaves of whole-grain bread.

The sales module will capture an order and update demand forecasts, while the inventory module will check ingredient availability in real time. For instance, if there’s enough flour or packaging.

Then, the procurement module will trigger purchase orders for missing supplies.

The production module schedules baking, enables batch tracking, and ensures recipes and allergen controls are followed, while the quality management module maintains compliance with safety standards.

The finance module records the transaction, updates accounts, and reflects it in revenue reports.

This is how ERP modules contribute to the whole task, helping you eliminate paperwork and streamline operations.

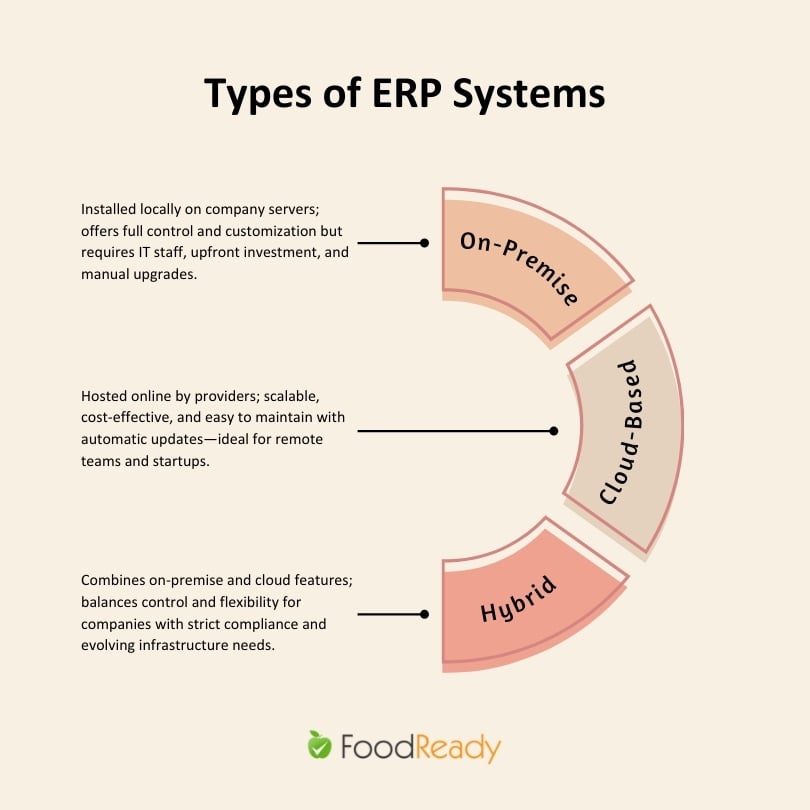

Types of Food ERP Systems

Food ERP software can be of three deployment types:

- Сloud

- On-premise

- Hybrid

On-premise ERP is installed on your company’s own servers. You must have an IT team to maintain it.

Its benefit is that it offers control of data and infrastructure, is customizable, and doesn’t need ongoing subscription costs.

It’s an excellent choice for companies following strict regulations. However, it still requires significant upfront investment and an IT team and can be time-consuming to upgrade and maintain.

On the contrary, cloud-based food ERP software is hosted via the Internet, and the solutions are managed by their providers. Because of that, they are less expensive, offer automatic updates, and are more scalable.

Companies with remote teams without an IT team will benefit from cloud software.

Still, you need to remember that cloud software is subscription-based and depends on the Internet network.

However, modern solutions have developed strategies to protect you from inconveniences and ensure security.

Hybrid ERP is a combination of both cloud and on-premise ERP solutions. This way, you can handle some ERP modules in the cloud while keeping the others on a local server.

Combining cloud and hybrid platforms is becoming more widespread. Gartner estimates that by 2027, 90% of organizations will adopt a hybrid cloud approach.

This ERP type is an excellent fit for food and beverage companies with unique compliance needs transitioning from on-premise to cloud. It offers both control and flexibility.

Still, it can be challenging to manage as it requires more coordination between IT and vendors.

7 Common Myths About Food ERP

There are many misconceptions about ERP, but I want to debunk these myths so you feel more confident about implementing the solution in your business.

Myth 1: ERP Is for Big Food Businesses Only

Originally, ERP solutions were built for big corporations, but now they are scalable and accessible to small and medium-sized businesses.

Software providers now offer different packages based on your business size and needs. For instance, you can look at FoodReady’s pricing for flexible offerings.

Myth 2: Food ERP Software Is Hard to Use

Modern ERP software for food manufacturers is user-friendly, and you don’t need to be an IT guru to understand and use it.

In many cases, software vendors also provide comprehensive training and onboarding.

You can learn to use ERP by watching built-in tutorials, receiving vendor support, and accessing online resources.

Myth 3: You Must Replace All Existing Systems With Food ERP Software

You don’t need to replace your systems. ERP can integrate with other business applications, streamlining the workflow and creating a centralized environment.

Myth 4: A Single Food ERP Solution Fits Everyone

As a food manufacturer, you should look for industry-specific solutions that meet your goals, needs, company size, etc.

Food ERP platforms are highly customizable and built to address your unique workflows, compliance needs, and challenges.

Myth 5: ERP, MRP, SCM, and CRM Are the Same

The solutions are related, but each one serves a different purpose for the business.

ERP integrates various business functions, SCM manages supply chains, CRM handles customer relationships, and MRP focuses on production planning.

They can still work together, and many food industry ERP software solutions have SCM, CRM, and MRP as integrated modules.

Myth 6: Food ERP Software Is Only for Managers

Enterprise resource planning systems benefit the whole company, including management and other employees, whether in the warehouse, customer service, or processing invoices.

Myth 7: Food ERP solutions are only to impress customers

Well, it’s not the purpose of ERP but rather a positive outcome.

ERP improves internal operations, streamlines workflows, reduces errors, and boosts productivity, contributing to a smoothly running business. It naturally leads to satisfied customers.

What Are the Benefits of Food ERP Software Solutions?

ERP is an indispensable tool nowadays, but to understand how it helps, let’s explore the advantages of food ERP software more.

1. Regulatory Compliance

We all know how valuable regulatory compliance is for food and beverage manufacturers.

Food and beverage ERPs have built-in compliance modules to help you prepare for audits, monitor regulations, and maintain records.

2. Improved Operational Efficiency

A synchronized and multifunctional working environment helps you streamline workflows, automate repetitive tasks, and save time.

Meanwhile, you can focus on your core competencies, ultimately boosting productivity.

3. Food ERP Platforms Promote Collaboration Across Departments

A single ERP solution helps centralize data and communication between departments.

Everyone involved will be notified of whatever happens in a module, eliminating duplicate data and miscommunication.

For instance, the production, sales, and quality assurance departments can coordinate efforts, share insights, and quickly respond to market changes or production issues, leading to a more cohesive operational strategy.

4. Cost Savings

According to a survey by Ultra Consultants, reducing operational costs is a key goal for 46% of businesses, making it one of the top three priorities in their ERP strategy.

Increased productivity, automation, audit readiness, etc., help you save costs, which is another food ERP benefit.

Although you must invest in the food ERP platform, it brings financial benefits in the long run.

5. Data Security

Modern food and beverage ERP solutions follow strict security protocols, protecting sensitive data. ERP providers now work harder to offer more safety than storing multiple paper records or using various platforms.

6. Scalability and Flexibility

Food ERP software is designed to be scalable, allowing food manufacturers to add new functionalities or accommodate increased production capacity easily.

It lets you choose what to work with first and customize the system to avoid cluttering your ERP with unnecessary modules.

7. Single Source of Truth and Better Decision-Making

The absence of ERP data leads to decision-making delays, according to 71% of businesses.

ERP software for food manufacturing shares the database over its modules and provides valuable insights that support strategic decision-making.

Food manufacturers can analyze trends, forecast demand, and identify areas for improvement, leading to more informed and effective business strategies.

8. Improved Customer Service

With food ERP software managing critical business processes, food manufacturers can respond to customer inquiries and orders more quickly and efficiently.

Access to accurate inventory levels, order histories, and production schedules enables businesses to provide better service and consistently meet customer expectations.

This improvement in customer satisfaction can lead to increased loyalty and repeat business.

9. Upgraded Quality Control

ERP software for food manufacturers plays a key role in embedding quality control directly into the heart of production, ensuring that every product meets standards before it leaves the facility.

By tracking quality metrics in real time and automating essential reports, food manufacturers can spot potential issues quickly and take action early.

This proactive approach not only boosts product quality but also helps lower the risk of food recalls.

How To Incorporate Food Safety Compliance in ERP Software?

Integrating compliance into your food manufacturing ERP system is necessary, considering increasingly strict regulations such as FDA’s FSMA, USDA standards, and GFSI-recognized certifications like SQF, BRC, and FSSC 22000.

How can you tailor your food ERP platform to support compliance?

The key is the food ERP’s compliance-oriented functionality.

The system is customizable enough to implement quality and compliance modules that will allow you to document standard operating procedures (SOPs), manage HACCP plans, track corrective actions (CAPA), and monitor critical control points (CCPs).

Also, integrated IoT sensors can help monitor temperature, sanitation schedules, logs, and ingredient traceability records.

This allows quicker identification of deviations before they become food safety hazards.

The system allows you to configure workflows to trigger alerts or approval steps when compliance issues occur so you don’t miss the smallest detail.

Other software features like document management and automated reporting make implementing robust safety measures easy.

Also, remember to train your team to keep them updated with food safety protocols and ensure their audit readiness.

Implementing food safety compliance into your food manufacturing ERP infrastructure creates a proactive culture of quality and accountability across your entire operation.

AI-Powered Food ERP Software That Simplifies Safety, Inventory, and Production

Unify inventory, production, compliance, and more with FoodReady’s scalable, AI-powered ERP software solution.

What Are the Challenges of Food ERP Software?

To get the benefits from an ERP, you must be ready for some challenges and drawbacks. So, what can happen while implementing and managing the ERP software?

1. Risks of Poor Strategy

Misaligned ERP strategies and high failure rates can become an obstacle for businesses. According to Gartner, over 70% of ERP initiatives won’t fully meet their original business goals by 2027, and up to 25% may fail.

What is the reason?

According to the survey, poor alignment between ERP strategy and overall business objectives is a problem for 75% of organizations. It highlights the importance of a clear ERP strategy.

2. ERP Costs Money

Another pitfall is high upfront costs, especially when talking about on-premise ERP. Yes, it’s not cheap, but it is an investment in your company’s future profit.

If you are contemplating implementing an ERP solution, you can compare different offerings based on your budget or choose a cloud solution.

3. Dealing With Resistance to Change

Another obstacle you might face is that workers may feel reluctant or nervous about using a new technology because it’s “complex.”

You must reassure the personnel that this is a myth and they can easily acquire a user-friendly ERP interface.

4. Deployment Requires Time and Effort

Deploying food manufacturing ERP software can be complex and time-consuming. However, it still depends on many factors, as each company is unique and has specific requests.

That’s why patience is key, and an implementation strategy to avoid delays is even more critical.

5. Data Migration to ERP

Data migration from legacy systems can also be a pain in the neck. You must devote time to organizing, cleaning, reorganizing, and transferring data to a new system.

6. Regulatory Compliance

Food businesses are subject to specific regulations, so you must put more effort into configuring and customizing the system to meet your compliance requirements.

That’s why I strongly recommend you choose an industry-specific solution.

Some of the Best Food ERP Software Systems

Choosing the right ERP is essential but can be difficult.

I have prepared a list of the best food ERP solutions to meet your needs.

1. FoodReady AI

FoodReady AI food ERP software is a versatile AI-powered tool featuring core modules like inventory, production, sales, procurement, finance, and advanced food safety management.

The software operates in the cloud, enabling the management of inventory, production, sales, purchasing, and quality. It includes smart lot tracking and full traceability to meet FDA and FSMA rules. Recent updates added AI HACCP planning and better recall tools, making record-keeping and audit preparation faster and easier.

More than 1000 companies now use the platform, which has helped them save up to 70% of their time on document management.

Best for: Small to large food and beverage manufacturers and co-packers that require an easy way to manage production, track ingredients, comply with food safety regulations, and maintain quality control.

ERP Software for Food Safety-Driven Teams

FoodReady AI combines food safety, production, inventory, and quality control into a single ERP solution that’s trusted by 1000+ facilities.

2. Microsoft Dynamics 365

Microsoft Dynamics 365 ERP is a customizable, secure, and scalable solution preferred by top companies like Nestlé. Its autonomous agents and an AI assistant drive automation and generate actionable insights.

The suite oversees finance, supply chain management, customer service, sales, human resources, and other key areas.

D365 can track lots, serial numbers, and expiration dates right away. It also supports FEFO (first-expired, first-out) and shelf-life planning through Business Central and Supply Chain tools.

Best for: Food and beverage companies of all sizes that require a scalable ERP with seamless integration into Microsoft 365 tools and a familiar interface.

3. NetSuite ERP

Built for food and beverage manufacturing and wholesale distribution, NetSuite provides maximum visibility into operations by managing accounting, inventory, orders, supply chain, and many other aspects.

It includes recipe management, quality checks, and recall workflows. Add-on apps help with lot and serial tracking as well as FEFO (first-expired, first-out) planning.

The software will help automate financial processes, gain inventory visibility, optimize the supply chain, improve order management, and streamline warehouse efficiency.

Best for: Mid-sized to large businesses that want one cloud system to manage perishable inventory and connect multiple operations in one system.

4. Oracle ERP Cloud

Oracle Fusion Cloud ERP provides AI, analytics, and automatic updates to streamline core business processes. The software deals with analytics, project and risk management, and other critical aspects.

Oracle ERP Cloud also covers finance, procurement, projects, and compliance. Food and beverage companies often utilize Oracle Supply Chain tools for enhanced traceability, logistics, and effective recall management. It also integrates with Oracle’s POS systems for restaurants and hospitality.

Best for: Large or global food businesses that need advanced finance, supply chain, and compliance features in one system.

5. SYSPRO

Established in 1978, SYSPRO is one of the longest-running privately owned ERP vendors globally.

SYSPRO supports full lot tracking, genealogy, and quick recalls. It includes recipe and batch management for industries like dairy, meat, and sauces. The software has flexible cloud or on-premise options and is easy to use on the plant floor.

This food manufacturing ERP software is designed to meet the unique needs of the food industry. It enables informed decisions quickly, contributes to profit growth, ensures food safety and supply chain visibility, and provides other benefits.

Best for: Small to mid-sized manufacturers that need strong compliance, traceability, and flexible deployment options.

6. Katana

Katana will help you manage inventory, production, and orders. The solution combines MRP elements with key ERP features like purchasing, sales, and warehouse management, making it an excellent fit for food manufacturers.

Katana tracks batches and expiration dates with simple tools and offers FEFO-style planning through an add-on. It connects easily with Shopify, accounting, and sales apps. The system is quicker to implement compared to traditional ERP. It takes only 6 weeks, while other ERPs take several months to a year.

Best for: Small-to-medium manufacturers and CPG startups that need easy inventory and production control without complex compliance features.

7. ERPNext

ERPNext offers a range of modules, including accounting, procurement, sales, CRM, and more.

It’s an open-source ERP with batch and expiry tracking, recipes, and quality checks. It can be cloud-based or self-hosted. Companies often customize it for compliance and recall reporting.

Best for: Smaller manufacturers or tech-savvy companies that want a low-cost, flexible ERP that they can adjust themselves.

8. QAD

QAD Adaptive ERP helps manage local and global operations. It’s an adaptable and scalable solution that focuses on industry-specific functionality, supporting everything from production to compliance.

The software caters to various food industry segments, encompassing fresh and frozen foods, as well as wine and spirits. It also helps you grow while maintaining sustainability and ESG.

QAD offers full traceability with lot and serial control, as well as FIFO/LIFO/expiry-based picking. It’s built for multi-site, multi-language operations and supports fast recalls. Cloud templates help standardize processes across plants.

Best for: Mid-sized to large manufacturers that operate across multiple sites and need global traceability and compliance.

9. DELMIAWorks (formerly IQMS)

The company offers a comprehensive ERP solution for food manufacturers. It connects all the facets of the business, including HR, finance, warehousing, QA, and more.

DELMIAWorks combines ERP with shop-floor monitoring, scheduling, and quality tools. It manages lots, serial numbers, and recalls in real time, which makes audits easier.

The industry-oriented solution will help you reduce costs, simplify audits, and efficiently handle inventory. DELMIAWorks is helpful if you want a unified solution that connects enterprise resource planning and manufacturing execution.

Best for: Mid-market manufacturers seeking an integrated ERP and MES solution to streamline production and compliance tracking.

10. BatchMaster ERP

BatchMaster offers two types of ERP: the ERP SME Edition, designed for emerging and growing manufacturers, and the ERP Enterprise Edition, built upon the SAP Business One platform, for larger enterprises.

BatchMaster adds recipe and formula management, compliance labeling, and mobile warehousing to SAP Business One. It supports FDA, FSMA, and GHS requirements.

Their ERP solutions help food businesses produce high-quality products, comply with industry regulations, and guarantee smooth workflow globally.

Best for: Food, nutraceutical, chemical, and pharmaceutical manufacturers that need an ERP built for formula-based production.

Considerations for Selecting Food ERP Software

Choosing the right food ERP platform is key for food manufacturers aiming to leverage technology for improved efficiency and growth.

You should consider various factors to ensure the selected system aligns with specific business needs and industry requirements.

Below are key considerations that can guide businesses when selecting an ERP solution.

1. Scalability

Food businesses require a solution that can grow with them, accommodating increased production volumes and expanding operations. Food manufacturing ERP system should be flexible enough to adapt to changing business needs.

2. Industry-Specific Features

Food industry ERP software must have batch tracking, quality control, compliance management, and other features to address specific industry standards.

An ERP system designed for food manufacturers will better support your business than a general manufacturing ERP software.

3. User-Friendly Interface

Food industry ERP software is only as good as its usability. Search for an intuitive interface that employees can easily navigate and use.

Training and support are also critical factors, as they will determine how quickly your team can adapt to the new system.

4. Integration Capabilities

Integrating with existing systems and third-party applications is crucial for a seamless transition.

An ERP system that can connect with other software solutions will ensure data consistency and improve overall efficiency.

5. Cost and ROI

Finally, consider the total cost of ownership and potential return on investment (ROI).

While ERP systems can be a significant investment, the long-term benefits often outweigh the initial costs. Evaluate the expected ROI to ensure the solution aligns with your business goals.

Real-World Examples of Successful ERP Implementation

Nestlé’s Transformation

Nestlé, one of the world’s largest food and beverage companies, implemented an ERP system to streamline its global operations.

The ERP solution helped Nestlé standardize processes across its numerous subsidiaries, improving efficiency and reducing costs.

The real-time data provided by the ERP system also enhanced decision-making capabilities, allowing Nestlé to respond quickly to market changes.

McCormick & Company’s Flavorful Success

McCormick & Company, a leader in the global spice market, turned to ERP to manage its complex supply chain.

The ERP system enabled McCormick to optimize inventory management, reduce waste, and ensure product quality. By integrating all aspects of its operations, McCormick achieved greater transparency and improved customer satisfaction.

General Mills’ Efficiency Boost

General Mills, known for its popular brands like Cheerios and Betty Crocker, implemented an ERP system to enhance its supply chain management.

The ERP solution provided visibility into every production stage, from raw material procurement to finished product distribution.

This visibility helped General Mills improve forecasting accuracy, reduce lead times, and increase overall efficiency.

Key Food ERP Trends To Observe

Technology is evolving at an insane pace, and the future of ERP has many bright prospects.

What are the food ERP trends that can define the direction of technology?

Firstly, even though the FDA intends to postpone the FSMA 204 compliance deadline to July 2028, it doesn’t mean food businesses should postpone their compliance efforts. This is a major trend for manufacturers these days.

By leveraging blockchain technology, IoT devices, and other food traceability technologies, ERP can help you get FSMA 204-ready.

Overall, compliance management is crucial as food and beverage regulations grow more complex.

Food manufacturing ERP systems will continue to evolve and help businesses keep up by automating compliance tasks and managing records.

Also, software providers increasingly integrate artificial intelligence and machine learning into their products to reduce manual work, forecast demand, optimize supply chains, predict maintenance needs, and enhance decision-making.

Next, more companies are shifting to cloud ERP systems because of their cost efficiency, scalability, and flexibility.

Food ERP software solutions are heading towards strengthening cybersecurity.

That is why, for instance, FoodReady AI food and beverage software has recently passed a SOC 2 audit to ensure better data protection.

Automation is no wonder in ERP technology, but autonomy is. Some think ERP systems won’t need human input to operate specific processes.

There’s also a growing need for vertical-specific ERP modules tailored to different industries. This is particularly helpful for food and beverage manufacturers.

Of course, sustainability efforts are getting more welcomed.

ERPs will support sustainability and Environmental, Social, and Governance (ESG) initiatives.

ERP will have features to monitor waste management, energy consumption, and carbon emissions.

These trends and many others will create more intelligent and flexible ERP platforms.

Food businesses should follow the news and trends and embrace innovations to stay competitive and responsive.

Revolutionize Your Food Business With FoodReady ERP

Implementing food ERP is complex, but FoodReady AI is here to help!

Our ERP solution can make daily operations easier, smarter, and more connected.

FoodReady AI brings its best functionality in one intuitive platform to benefit large and small food manufacturers, multi-location distributors, or other food industry specialists.

The AI-powered food ERP software offers various modules, including sales, inventory, procurement, production, finance, etc.

This way, you eliminate disconnected spreadsheets, lost data, or surprise stockouts and transfer your food and beverage operations to a digital platform.

In one app, you can track orders, schedule production, manage suppliers, and generate reports.

Our food and beverage software is also scalable enough to start by adding essential modules and expand the functionality later.

Most importantly, we understand the unique challenges of the food and beverage industry and have designed our system to help you always stay compliant, organized, and audit-ready.

For example, Up at Dawn Bakery, a high-volume production facility of mini muffins, stumbled upon FoodReady by chance and was extremely satisfied with the software.

FoodReady helped reduce labor hours and costs and eliminated a lot of paperwork:

“…I love how much paper usage I have eliminated since switching over to using an app…” (Erika Wood, Up at Dawn Quality Manager).

Up at Dawn Bakery shifted to a solution that can grow with them and support environmentally conscious initiatives. Moreover, with FoodReady’s support and guidance, they passed a BRC audit with an AA+ score!

If you’re ready to take control of your business, reduce manual work, and make decisions based on real-time data, FoodReady ERP is here to support you.

Contact us to book a demo and get started!

Conclusion

Food manufacturing ERP systems are revolutionizing the food industry by streamlining food safety compliance, improving operational efficiency, and supporting better decision-making.

The ERP history has evolved into a comprehensive and customizable solution for the food industry, with modules that handle finance, inventory, quality, customer relationships, and other crucial aspects.

Implementing the system can be challenging, requiring costs, time, and effort. What’s more, you may face some confusing misconceptions.

However, awareness of them helps you better understand food ERP’s peculiarities and implement the system to get as many benefits as possible.

Implementing a cloud, on-premise, or hybrid ERP will bring food handlers various advantages, from increased operational efficiency and cost optimization to streamlined regulatory compliance and complete data overview.

The food ERP has excellent potential and will become an even more comprehensive, AI-driven, and secure platform.

It’s not just a tool; it’s a strategic asset that can drive success in the fast-paced and complex world of food manufacturing.

Implement ERP today to increase your business’s profit, save person-hours, and improve food quality and safety.

Book a demo with FoodReady to start your journey!

FAQs

ERP is a tool for businesses of all sizes. Common industry users are food and beverage companies, distributors, retailers, and food service providers.

Yes! ERP is not only for large enterprises. There are cloud and scalable solutions that can fit small businesses as well.

Yes, restaurants use ERP systems to manage inventory, finance, etc.

The signs include relying heavily on spreadsheets, struggling with duplicate data, weak department visibility, or frequent inventory issues.

Also, if you have trouble tracking orders or financials in real time, your systems don’t talk to each other, or your team spends more time fixing data than using it, it’s time to consider ERP.

While ERP helps manage different aspects of the business, CRM is responsible for customer relationship management, and it can be a separate ERP module.

Despite the user-friendly interface, some training is typically needed, especially during initial setup.

For a small food business generating between $200,000 and $500,000 in annual revenue, with profit margins of around 56% and startup costs of $50,000 to $200,000, choosing the right ERP solution involves careful consideration of both initial and long-term expenses.

Generally, cloud-based ERP solutions appeal to businesses seeking lower upfront investments, typically requiring around $20,000 to $30,000 in initial setup, running your business and juggling multiple spreadsheets, documents, and notes. I think you would be way more productive with an ERP system.

Enterprise Resource Planning (ERP) brings all the parts of your business into one place, making the processes smoother and faster.