Food allergies aren’t just a dietary preference or a passing health trend. For millions of people, they’re a serious medical condition that can turn a simple bite of food into a hospital visit or worse. Whether it’s a splash of milk in a sauce or a trace of peanut dust on a cutting board, even the tiniest exposure can trigger severe allergic reactions. And when you’re running a kitchen or manufacturing facility, that’s a responsibility you simply can’t afford to ignore.

Undeclared allergens are one of the top reasons for food recalls globally.

I’ve talked to restaurant owners blindsided by allergic reactions because a staff member wasn’t trained. The truth is, in this increasingly allergen-aware world, you need to be aware of the Big 9 food allergens to keep your business resilient.

In this guide, I’ll explain the Big 9 allergens, why they matter, and how you can confidently manage them across your food operations.

What Are the Big 9 Food Allergens?

You must have likely heard the phrase “Big 9 allergens” more times than you can count. But do you know where it comes from and why it matters to your operations?

The term “Big 9” comes from the Food Allergen Labelling and Consumer Protection Act (FALCPA), passed in 2004. The U.S. Food and Drug Administration (FDA) identified these nine foods responsible for 90% of all serious allergic reactions in the United States. Since then, they’ve become the cornerstone of allergen labelling laws and food safety protocols nationwide.

For manufacturers like yours, every ingredient you use and every process you implement must precisely account for the Big 9. One undeclared allergen or cross-contact incident can endanger lives and lead to costly recalls, fines, or brand damage.

The Big 9 Food Allergens (And What They Include)

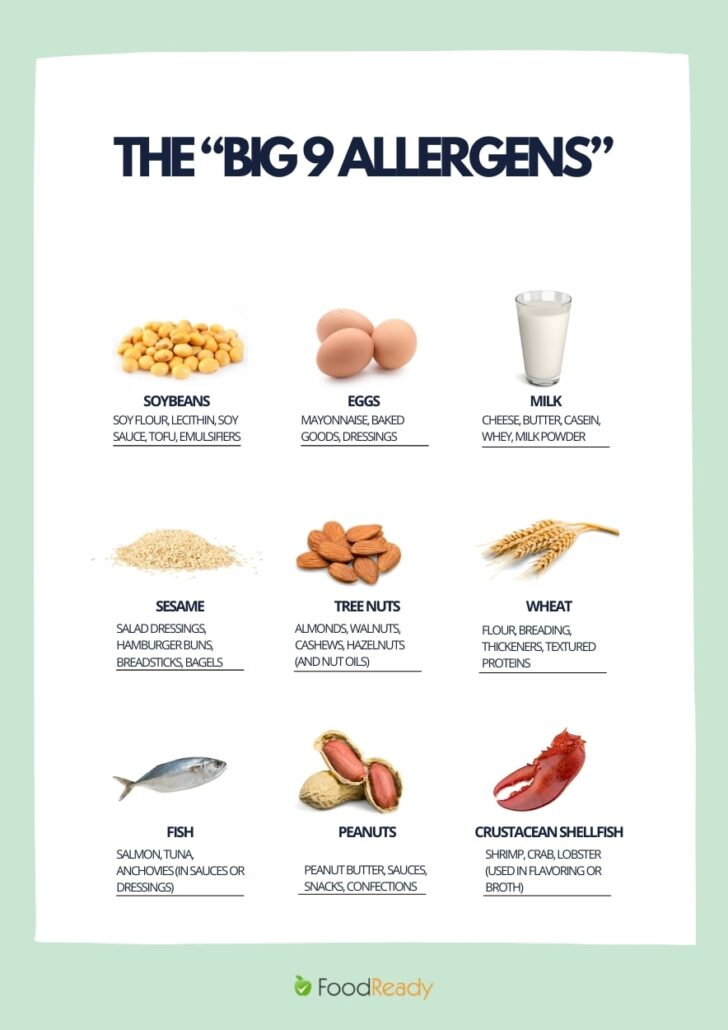

Here’s a breakdown of the Big 9 allergens you must manage in your facility:

| Allergen | Common Sources in Manufacturing |

|---|---|

| Milk | Cheese, butter, casein, whey, milk powder |

| Eggs | Mayonnaise, baked goods, dressings |

| Fish | Salmon, tuna, anchovies (in sauces or dressings) |

| Crustacean Shellfish | Shrimp, crab, lobster (used in flavoring or broth) |

| Tree Nuts | Almonds, walnuts, cashews, hazelnuts (and nut oils) |

| Peanuts | Peanut butter, sauces, snacks, confections |

| Wheat | Flour, breading, thickeners, textured proteins |

| Soybeans | Soy flour, lecithin, soy sauce, tofu, emulsifiers |

| Sesame | Salad dressings, hamburger buns, breadsticks, bagels |

Tip: Cross-check your ingredient specs and supplier data regularly. Even shared equipment from suppliers can introduce allergen risks. If you need help managing this, our FoodReady traceability tools are built precisely for this purpose.

Why It Matters to Your Manufacturing Line?

The Big 9 aren’t just a consumer issue but an operational concern. From bulk storage to batching and packaging, every step of your production line must be assessed for allergen exposure. And if you’re running multiple product lines with different allergen profiles, the risk of cross-contact rises significantly.

An effective Food Safety Management System, supported by allergen SOPs, visual controls, and thorough employee training, can shield both your consumers and your business from potential risks.

Why the Big 9 Matter in the Food Industry?

As a food safety consultant working with manufacturers of all sizes, I can confidently say this: If you’re not prioritising allergen control, you’re taking a risk you can’t afford. The Big 9 allergens don’t just pose a health risk; they also carry serious regulatory, reputational, and operational consequences.

The Growing Prevalence of Food Allergies

Food allergies are no longer rare. In the U.S. alone, the CDC confirms that approximately 8% of U.S. children have a diagnosed food allergy. And these aren’t just mild sensitivities. We’re talking about life-threatening anaphylactic reactions caused by trace exposures.

As a manufacturer, you operate in a market where allergen awareness is rapidly growing. Your customers, whether distributors, restaurants, retailers, or end consumers are demanding transparency, safety, and trustworthy allergen labelling.

Legal Implications & FDA Requirements (FALCPA)

The Food Allergen Labeling and Consumer Protection Act (FALCPA) has been in effect since 2006, and it mandates clear labeling for the Big 9 allergens on packaged foods sold in the U.S.

This means:

- If your product contains even a trace of a Big 9 allergen, it must be declared using plain English terms (e.g., “Contains: Milk”).

- If your product is not properly labelled, it can be considered misbranded under federal law.

- Failing to meet allergen labelling requirements may result in recalls, enforcement actions, or legal liability.

In my experience, some teams have faced unexpected recalls because allergens weren’t properly disclosed, the result of supply chain issues or outdated recipe data. It’s a painful and expensive mistake, one that’s entirely preventable with the right systems.

Risks of Cross-Contamination and Poor Labeling

Even if your product doesn’t intentionally contain allergens, the risk of cross-contact during processing is very real. Think about shared mixers, air ducts, scoops, or packaging lines. One improperly cleaned surface can lead to contamination, and one contaminated unit can trigger a recall or lawsuit.

Poor communication across teams, outdated batch sheets, and lack of verification protocols only add to the danger. I’ve helped facilities identify critical allergen control points they never considered, like how allergens are handled during product changeovers or where ingredient bags are stored in the warehouse.

Understanding Each Allergen in Your Production Line

Over time, I’ve discovered that understanding how each allergen behaves in your workflow is one of the most important factors in preventing contamination. Here’s a detailed breakup for each:

1. Milk

- Sources: Milk powders, whey, caseinates, butter, cheese.

- Hazard: Fine milk powders can aerosolize and settle on non-dairy lines.

- Control Tips: Use dedicated lanes or schedule dairy runs last, then deep-clean with validated testing.

2. Eggs

- Sources: Whole egg or yolk powders, albumin in coatings and baked goods.

- Hazard: Similar to milk powders, stick to surfaces and utensils.

- Control Tips: Color-code utensils and store eggs away from general ingredients.

3. Fish & Shellfish

- Sources: Fillets, seafood broths, flavor extracts.

- Hazard: Oils and residues cling to equipment even after washing.

- Control Tips: Mandatory separation of fish/shellfish production zones, labeled drains.

4. Tree Nuts & Peanuts

- Sources: Whole nuts, nut flours, nut oils.

- Hazard: Airborne dust, oil carryover, and shared grinder use.

- Control Tips: Install HEPA filters, use fat-fraction testing, and train staff to prevent cross-contact during changeovers.

5. Wheat

- Sources: Flours, bran, starches, gluten.

- Hazard: Dust spreads easily, lingering granules can contaminate sweet production.

- Control Tips: Enforce complete sweep-clean protocols and track production run schedules.

6. Soybeans

- Sources: Soy flour, lecithin, soy protein concentrates.

- Hazard: Lecithin in coatings is often overlooked.

- Control Tips: Always verify supplier specs and include soy in allergen risk assessments.

Why These Allergen Profiles Matter?

Each of the Big 9 behaves differently in your facility powders cling, oils linger, proteins get airborne. Without tailored controls you risk:

- Cross-contact during shared equipment runs.

- Mislabeling due to hidden ingredients.

- Inadequate cleaning leaving residue unseen and untested.

How Allergens Behave in Your Production Line?

As a food safety professional who’s walked the floors of countless food manufacturing plants, I can tell you this: the danger of allergens doesn’t just lie in the ingredients list.t’s in how those ingredients move through your facility. The way allergens behave during processing, storage, and changeovers can introduce hidden risks that many operations don’t even realize exist.

So instead of repeating what the Big 9 are, let’s talk about how they show up operationally, and how you can manage them proactively.

1. Airborne Allergen Risks: It’s Not Just What You Touch

Ingredients like milk powders, wheat flour, and egg proteins don’t need direct contact to cause problems. These fine particles can become airborne during mixing, sifting, or dumping, and settle on surfaces across zones.

Example: I once audited a bakery where egg powder was used in one mixer, but it tested positive for residue two zones away, simply due to unfiltered airflow.

Solution: Use HEPA filters, implement physical barriers, and schedule high-risk allergen processing when fewer lines are active.

2. Cross-Contact via Shared Equipment & Utensils

Shared slicers, conveyors, totes, and even scoops can be a major source of cross-contact, especially with sticky allergens like peanut butter or nut oils that cling to surfaces.

Tip: Oils and pastes require more than just a standard rinse. You need validated allergen-specific cleaning protocols, and yes, sometimes visual inspection just isn’t enough.

Use FoodReady AI’s sanitation to assign and verify deep-cleaning tasks between allergen runs.

3. Packaging Errors & Labeling Breakdowns

Allergen exposure doesn’t always happen in production, it often happens at the very end, in labeling and packaging. A mismatched label or outdated ingredient deck is all it takes to land your product on the recall list.

Common Scenario: Labels were updated in R&D, but production was still using old inventory rolls. The result? Undeclared allergens and a costly product withdrawal.

4. Hidden Allergens in Compound Ingredients

Soy lecithin in chocolate coatings, casein in seasoning blends, or fish-based Worcestershire sauce, these “stealth allergens” often get overlooked, especially in compound ingredients or imported raw materials.

Always request updated allergen declarations and spec sheets from your suppliers. Better yet, build a centralized supplier documentation system to keep everything traceable and audit-ready.

5. Human Error & Lack of Allergen Training

No matter how good your SOPs are, one improperly trained team member can undo everything. From scooping allergen flour into the wrong bin to skipping a cleaning step, human error is still the top cause of allergen incidents in facilities I’ve reviewed.

Schedule regular team allergen training sessions, track completion, and test knowledge using digital logs or QR-code based assessments, features we’ve embedded into FoodReady AI’s mobile FSMS tools.

Final Thoughts

Managing food allergens is about protecting lives, earning trust, and safeguarding your brand, it isn’t just about ticking boxes for compliance.

The Big 9 allergens are responsible for the vast majority of serious food allergy incidents, and they require your unwavering attention at every stage of your production. From procurement and processing to packaging and people, every aspect of your facility must be aligned with allergen awareness and control.

Remember: it only takes one missed label, one improper cleaning, or one untrained employee to turn a batch into a liability.

The Big 9 allergens: milk, eggs, fish, crustacean shellfish, tree nuts, peanuts, wheat, and soybeans; account for around 90% of all serious food allergies in the U.S. They are recognized by the FDA and must be clearly labeled on all packaged foods. Managing them properly helps you protect consumers and avoid costly recalls.

From time perspective, sesame is considered the 9th major allergen in the U.S., following the FASTER Act, which took effect in 2023.

Preventing cross-contact requires a combination of strategies:

– Segregated storage and dedicated equipment.

– Validated cleaning procedures

– Proper production scheduling (non-allergen runs first)

– Employee training and allergen-specific SOPs

Tools like FoodReady’s FSMS can help track, train, and verify these controls.

Yes. Under FALCPA, if an ingredient or processing aid contains a Big 9 allergen (even in trace amounts), it must be declared clearly using plain English terms like “Contains: Milk.” Relying on “may contain” statements alone is not considered good practice.

Hidden allergens are ingredients that contain Big 9 allergens but may not be obvious. Common examples include:

– Whey or casein in spice blends

– Soy lecithin in coatings

– Fish-based flavorings in sauces

These can slip through if you don’t regularly review supplier specs and compound ingredient declarations.

At a minimum, allergen training should be done:

– During onboarding

– Whenever processes or product lines change

– At regular intervals (quarterly or biannually)