Identify food safety hazards, set critical limits, and document procedures with our customizable chocolate HACCP template and AI HACCP builder.

Create a USDA-approved HACCP plan for chocolate products.

Chocolate products currently fall under the regulatory rules of the U.S. FDA’s Food Safety Modernization Act (FSMA) for Preventive Controls for Human Food and local State Health Departments.

Here, you’ll find the essential steps to create a food safety plan that satisfies both state and federal regulations.

Worried about your special business needs? You can customize the template with FoodReady consultants.

A HACCP plan is vital to your food safety system, but is not the only part. Prerequisite programs, such as GMPs (Good Manufacturing Practices), must be in place to support your HACCP plan. USDA Section 402(a)(3) mandates safe food processing practices under sanitary conditions, including:

Here is an example of a process flow diagram for chocolate manufacturing:

Steps:

Monitoring records and logs must include the actual values or observations that document the actual implementation of a food safety plan.

For example, it should be the exact temperature recorded, not just a checkmark that the temperature complied with the critical limit.

To comply with regulations, you must record the information when you observe it.

Recommended logs for chocolate facilities:

The safety of your product goes beyond your facility.

If an ingredient has a history of association with a specific hazard, a supply chain program may be required to control that risk within your food safety plan.

Many companies also implement broader supplier programs to monitor performance and ensure compliance beyond food safety.

Required documentation may include:

SOPs are related to GMPs and controls of hazards in a food safety plan.

SOPs define the steps of how GMPs and Controls of Hazards mitigate food safety hazards and define a repeatable process.

Recommended SOPs include:

The following associated food safety components are recommended to achieve compliance with State and Federal rules and regulations.

According to the Food Safety Modernization Act (FSMA), Preventive Controls for Human Food regulation requires a written Recall Plan when a hazard analysis identifies a hazard requiring a preventive control.

Recalls are actions an establishment takes to remove an adulterated, misbranded, or violative product from the market.

In other words, a product for which the FDA or a state could take legal action against the company would be recalled.

Verification is essential to the supply chain, sanitation, allergen, and critical controls. It confirms that the HACCP Plan is operating as intended.

Validation confirms the effectiveness of the HACCP Plan. The purpose of verification is to make sure that the HACCP Plan is:

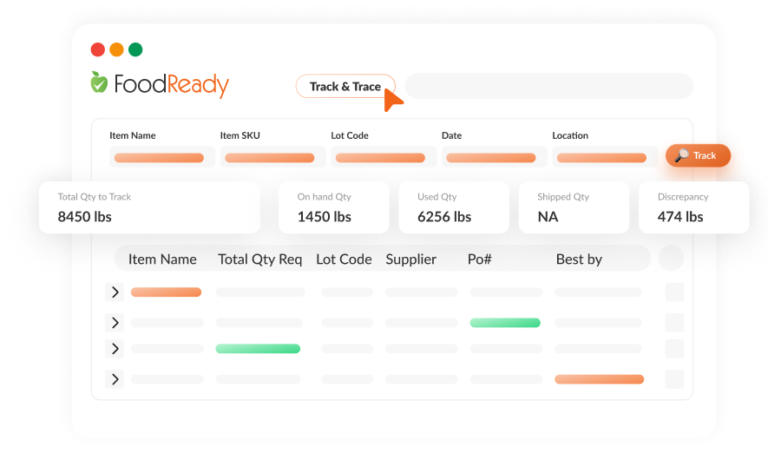

Stop relying on spreadsheets or outdated systems.

Use FoodReady to automate inventory tracking, improve traceability, and reduce waste.

© FoodReady 2026. All Rights Reserved.